Dehydrating agent, preparation method and application thereof, and red mud dehydration method

A dehydrating agent, red mud technology, applied in water/sludge/sewage treatment, chemical instruments and methods, sludge treatment, etc., can solve the problems of long time, high energy consumption, poor dehydration effect, etc. Heat, increase evaporation rate, increase the effect of dehydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This embodiment provides a red mud dehydration method, the specific steps are as follows:

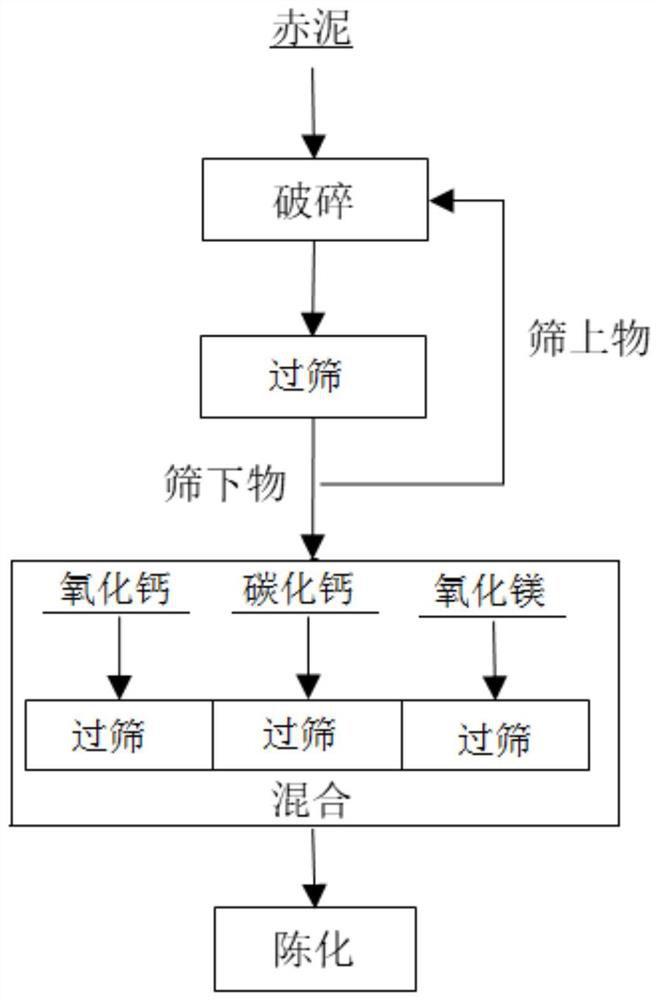

[0035] CaO, MgO, CaC 2 After crushing through a 200-mesh sieve, take the under-sieve according to CaO, MgO, CaC 2 The mass ratio is 2:2:1 and mixed evenly to obtain the dehydrating agent;

[0036]The red mud transported back from the red mud yard is placed in the red mud raw material warehouse (the red mud produced by the Bayer method to produce alumina), and then the red mud is crushed and passed through a 10mm sieve. Re-crushing, the underscreen is sent to the feeding area through the conveyor belt (after testing, the water content of the red mud is 25%), and the dehydrating agent is transported to the feeding area by a vibrating feeder; among them, the mass of the red mud in the feeding area is 100kg, dehydration The mass of the agent is 9kg; the red mud in the feeding area and the dehydrating agent are sent to the screw mixer for mixing evenly, and the mixed material is sen...

Embodiment 2

[0038] This embodiment provides a red mud dehydration method, the specific steps are as follows:

[0039] CaO, MgO, CaC 2 After crushing through a 200-mesh sieve, take the under-sieve according to CaO, MgO, CaC 2 The mass ratio is 2:2:1 and mixed evenly to obtain the dehydrating agent;

[0040] The red mud transported back from the red mud yard is placed in the red mud raw material warehouse (the red mud produced by the Bayer method to produce alumina), and then the red mud is crushed and passed through a 10mm sieve. Re-crushing, the underscreen is sent to the feeding area through the conveyor belt (after testing, the water content of the red mud is 24%), and the dehydrating agent is transported to the feeding area by a vibrating feeder; among them, the mass of the red mud in the feeding area is 100kg, dehydration The quality of the agent is 3kg; the red mud in the feeding area and the dehydrating agent are sent to the screw mixer to mix evenly, and the mixed material is sen...

Embodiment 3

[0042] This embodiment provides a red mud dehydration method, the specific steps are as follows:

[0043] CaO, MgO, CaC 2 After crushing through a 200-mesh sieve, take the under-sieve according to CaO, MgO, CaC 2 The mass ratio is 2:2:1 and mixed evenly to obtain the dehydrating agent;

[0044] The red mud transported back from the red mud yard is placed in the red mud raw material warehouse (the red mud produced by the Bayer method to produce alumina), and then the red mud is crushed and passed through a 10mm sieve. Re-crushing, the underscreen is sent to the feeding area through the conveyor belt (after testing, the water content of the red mud is 24%), and the dehydrating agent is transported to the feeding area by a vibrating feeder; among them, the mass of the red mud in the feeding area is 100kg, dehydration The quality of the agent is 6kg; the red mud in the feeding area and the dehydrating agent are sent to the screw mixer for mixing evenly, and the mixed material is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| dehydration rate | aaaaa | aaaaa |

| dehydration rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com