Highly environmental-friendly flame retardant reinforced PC (Polycarbonate)/ABS (Acrylonitrile Butadiene Styrene) blending material and preparation method thereof

An environmentally friendly and blending technology, applied in the field of polymer materials, to achieve high strength, short burning time, and high environmental protection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

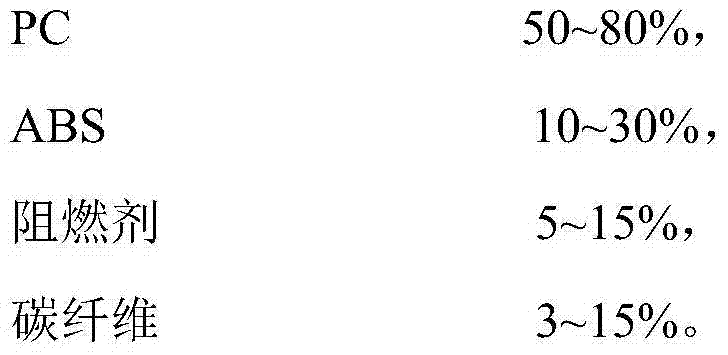

Method used

Image

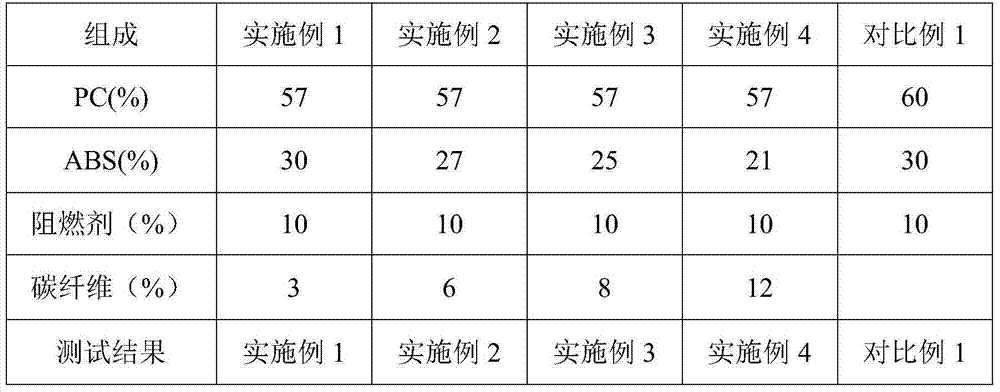

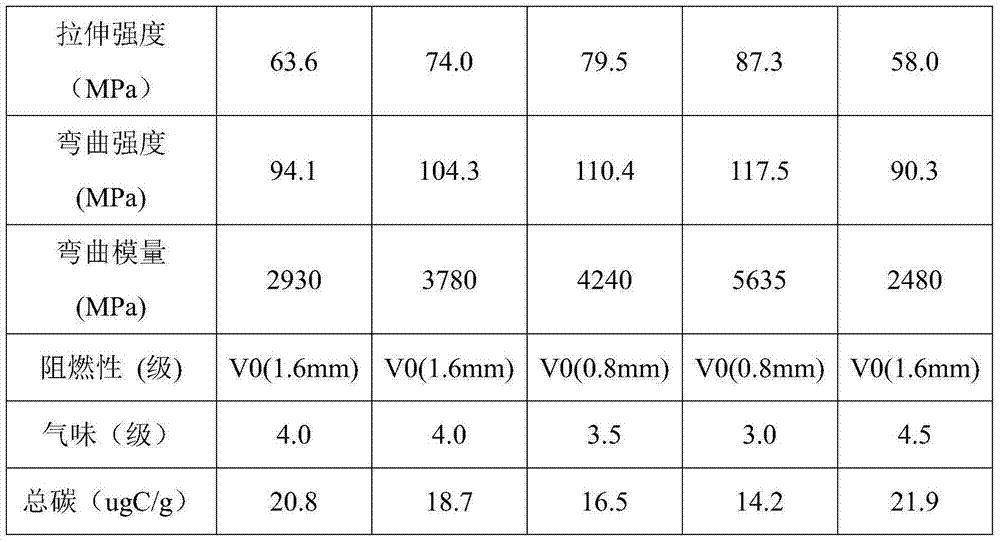

Examples

Embodiment 1

[0032] Soak 3g of carbon fiber in 1mol / L NaOH solution for 24 hours, take it out and filter it, put it into a muffle furnace, burn it at 600°C under aerobic conditions for 30 minutes, rinse it repeatedly with deionized water after cooling, and dry it The carbon fiber after surface activation treatment is obtained.

[0033] Weigh 57g of PC resin, 30g of ABS resin, and 10g of flame retardant, and put them into a high-speed mixer together with 3g of carbon fiber and mix them evenly. Put the obtained mixed raw material into the main feeding bin of twin-screw extrusion, and put it into the barrel of the main machine through the feeding screw. The diameter of the screw of the extruder is 35 mm, the ratio of length to diameter L / D=36, and the speed of the main machine is 400 rpm , the control temperature of each section of the main barrel (from the feed port to the outlet of the machine head) is 215°C, 220°C, 225°C, 230°C, 230°C, 230°C, and the speed of the main engine is 300 rpm. Af...

Embodiment 2

[0035] Soak 6g of carbon fiber in 1mol / L NaOH solution for 24 hours, take it out and filter it, put it in a muffle furnace, burn it at 600°C under aerobic conditions for 30 minutes, rinse it repeatedly with deionized water after cooling, and dry it The carbon fiber after surface activation treatment is obtained.

[0036] Weigh 57g of PC resin, 27g of ABS resin, and 10g of flame retardant, put them into a high-speed mixer together with 6g of carbon fiber and mix them evenly. Put the obtained mixed raw material into the main feeding bin of twin-screw extrusion, and put it into the barrel of the main machine through the feeding screw. The diameter of the screw of the extruder is 35 mm, the ratio of length to diameter L / D=36, and the speed of the main machine is 400 rpm , the control temperature of each section of the main barrel (from the feed port to the outlet of the machine head) is 215°C, 220°C, 225°C, 230°C, 230°C, 230°C, and the speed of the main engine is 300 rpm. After me...

Embodiment 3

[0038] Soak 8g of carbon fiber in 1mol / L NaOH solution for 24 hours, take it out and filter it, put it into a muffle furnace, burn it at 800°C under aerobic conditions for 30 minutes, rinse it repeatedly with deionized water after cooling, and dry it The carbon fiber after surface activation treatment is obtained.

[0039] Weigh 57g of PC resin, 25g of ABS resin, and 10g of flame retardant, and put them into a high-speed mixer together with 8g of carbon fiber and mix them evenly. Put the obtained mixed raw material into the main feeding bin of twin-screw extrusion, and put it into the barrel of the main machine through the feeding screw. The diameter of the screw of the extruder is 35 mm, the ratio of length to diameter L / D=36, and the speed of the main machine is 400 rpm , the control temperature of each section of the main barrel (from the feed port to the outlet of the machine head) is 215°C, 220°C, 225°C, 230°C, 230°C, 230°C, and the speed of the main engine is 300 rpm. Af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com