A kind of preparation method of water-based eva surface treatment agent

A surface treatment agent, water-based technology, applied in the field of preparation of water-based surface treatment agents, can solve the problems of high cost of hydroxyl-terminated polyolefins, health effects of operators, and environmental pollution, etc., to achieve good affinity and significant adhesion promotion Function, environment-friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

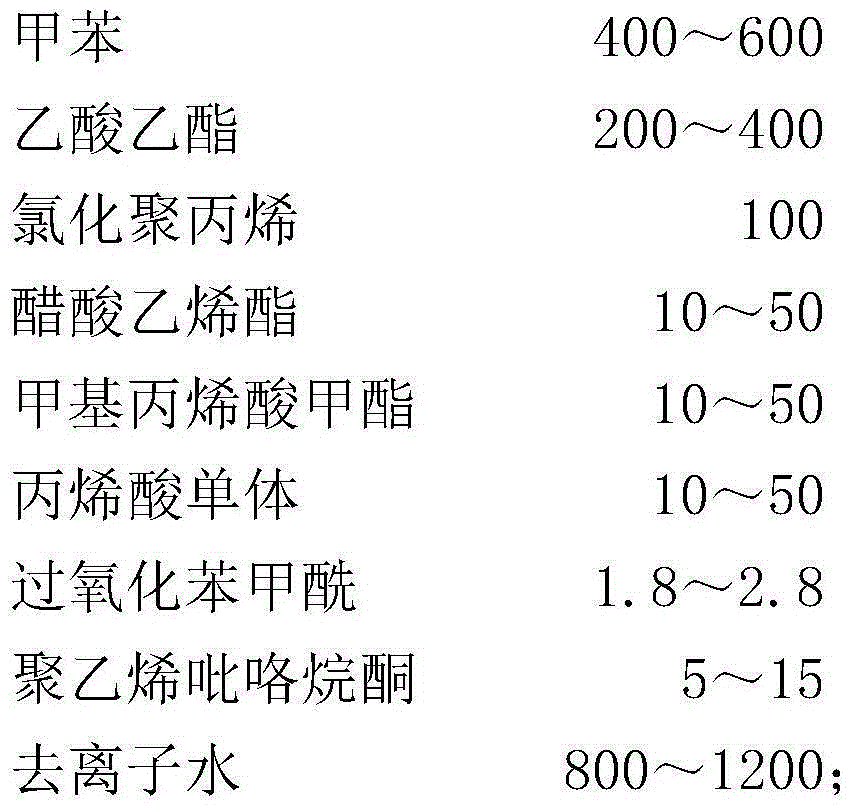

Embodiment 1

[0021] Add 400 grams of toluene and 200 grams of ethyl acetate into a reaction flask equipped with a thermometer, a nitrogen device, a mechanical stirring device, a vacuum device and a reflux device, then drop into 100 grams of chlorinated polypropylene, stir, and control the temperature at 60 ℃. After the chlorinated polypropylene is completely dissolved, fill the reaction flask with nitrogen, add 10 grams of methyl methacrylate and 10 grams of acrylic acid, and add 1.8 grams of benzoyl peroxide and 10 grams of acetic acid dropwise after heating up to 75°C A mixed solution of vinyl esters was polymerized; after 3 hours of polymerization, the nitrogen gas was turned off, the temperature was lowered to 50°C, and 50% of the solvent in the system was removed by distillation under reduced pressure, and then 10wt% triethylamine aqueous solution was added until the pH value of the system was 6.5, and the reaction 0.5 hours; gradually add 800 grams of deionized water at 50°C under hi...

Embodiment 2

[0023] 420 gram toluene, 220 gram ethyl acetate are added in the reaction flask that has thermometer, nitrogen device, mechanical stirring device, vacuumizing device and reflux device, then drop into 100 gram chlorinated polypropylene, stir, control temperature is 62 ℃. After the chlorinated polypropylene is completely dissolved, fill the reaction flask with nitrogen, add 15 grams of methyl methacrylate and 15 grams of methacrylic acid, and add 1.9 grams of benzoyl peroxide and 15 grams of methacrylic acid dropwise after heating up to 76 ° C. The mixed solution of gram vinyl acetate carries out polymerization reaction; After 3.5 hours of polymerization reaction, turn off the nitrogen gas, cool to 51 ℃, then remove 55% of the solvent in the system by distillation under reduced pressure, then add 10wt% dimethylaminoethanol aqueous solution to the pH value of the system 7. React for 40 minutes; gradually add 850 grams of deionized water at 51°C under high-speed stirring, and fina...

Embodiment 3

[0025] Add 450 grams of toluene and 250 grams of ethyl acetate into a reaction flask equipped with a thermometer, a nitrogen device, a mechanical stirring device, a vacuum device and a reflux device, then drop into 100 grams of chlorinated polypropylene, stir, and control the temperature at 65 ℃. After the chlorinated polypropylene is completely dissolved, fill the reaction flask with nitrogen, add 20 grams of methyl methacrylate and 20 grams of acrylic acid, and add 2.0 grams of benzoyl peroxide and 20 grams of acetic acid dropwise after heating up to 78°C A mixed solution of vinyl esters was polymerized; after 4 hours of polymerization, the nitrogen gas was turned off, the temperature was lowered to 52°C, and 60% of the solvent in the system was removed by distillation under reduced pressure, and then 10wt% triethylamine aqueous solution was added until the pH value of the system was 7.5, and the reaction 50 minutes; under high-speed stirring, gradually add 900 grams of deio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com