A kind of strapping for deep sea buoyancy material and preparation method thereof

A technology of buoyancy material and strapping, applied in the field of marine equipment, strapping and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

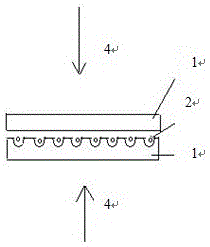

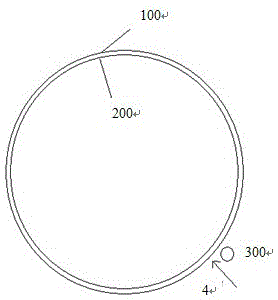

[0049] Take 100 parts of EPDM rubber (ethylidene norbornene is the third monomer), 40 parts of carbon black, 1 part of polyene-based radiation sensitizer TAIC, 10100.5 parts of antioxidant, plasticizer adipic acid di 0.5 parts of decyl ester, 0.5 parts of zinc stearate as a stabilizer, and 0.5 parts of a surface treatment agent were placed in a high-speed mixer in turn and stirred at a high speed for 5 minutes, 500 rpm, and the material did not exceed 60 °C. Take out the material and put it into a twin-screw extruder to extrude into a figure 1 Shown is EPDM 1 with grooved structure and a smooth belt without grooved structure. The carbon fiber is wound on a large heatable circular roller 200 of EPDM 1 with a grooved structure, and then attached with a smooth rubber band. Wherein the groove spacing is 1 mm, the rubber belt width is 5 cm, and the ring rubber belt diameter is 1.2 meters. Afterwards, the big roller is heated to 140°C, and the small roller 300 extrudes the three-l...

Embodiment 2

[0051] Take 100 parts of EPDM rubber (1,4-hexadiene is the third monomer), 50 parts of carbon black, 1.5 parts of polyene-based radiation sensitizer TMPTMA, 10100.5 parts of antioxidant, plasticizer Put 0.5 part of didecyl adipate, 0.5 part of zinc stearate as a stabilizer, and 0.5 part of surface treatment agent into a high-speed mixer and stir for 5 minutes at a high speed, 500 rpm, and the material does not exceed 60 °C. Take out the material and put it into a twin-screw extruder to extrude into a figure 1Shown is EPDM 1 with grooved structure and a smooth belt without grooved structure. The glass fiber is wound on a large roller 200 of EPDM 1 with a grooved structure, and then a smooth rubber band is attached. Wherein the pitch of the grooves is 2mm, the width of the rubber belt is 5cm, and the diameter of the annular rubber belt is 1.2 meters. Afterwards, the large roller 200 is heated to 140°C, and the small roller 300 extrudes the three-layer structure of the strappin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com