A kind of methyl phenyl silicone resin and preparation method thereof

A technology of methyl phenyl silicon and methyl alkoxy silane, applied in the field of methyl phenyl silicone resin and its preparation, can solve the problems of complicated operation, the heat resistance needs to be further improved, etc., and achieves a good heat resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] In a 250 mL four-necked flask were sequentially added 15 g of phenyltrimethoxysilane, 15 g of methyltrimethoxysilane, 0.07 g of potassium hydroxide, and 180 g of toluene. Then, 6ml of water was added dropwise for 10min. After the addition, the temperature was raised to 65°C and refluxed for 12h. After the reaction was completed, it was allowed to stand for layering. After the solution was cooled to room temperature, a white substance was obtained by filtration. Put the obtained white product into a vacuum oven at a temperature of 150° C. and a vacuum degree of -0.08 MPa, and dry for 5 hours to obtain a white powdery substance. The yield of the silicone resin obtained by this method is 65%.

[0033] The silicone resin obtained by the above method is tested, and the test method and conditions are as follows:

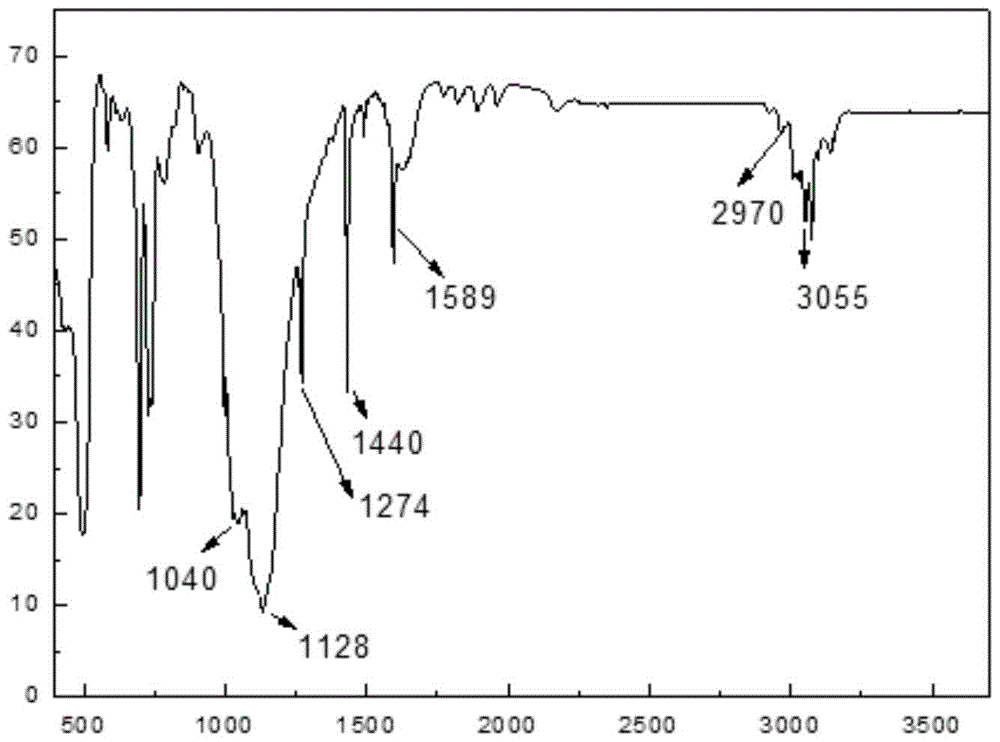

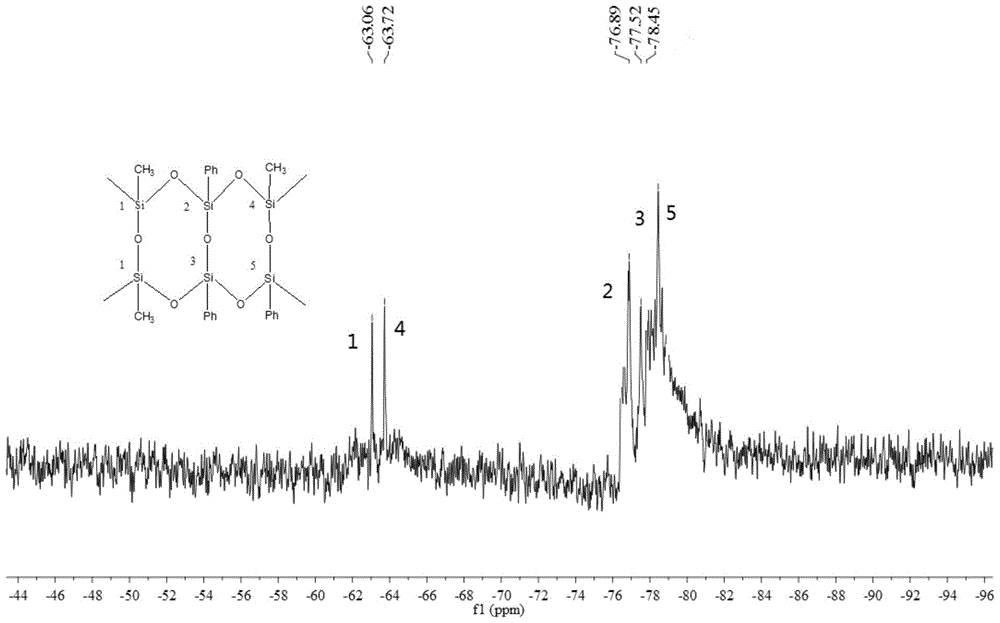

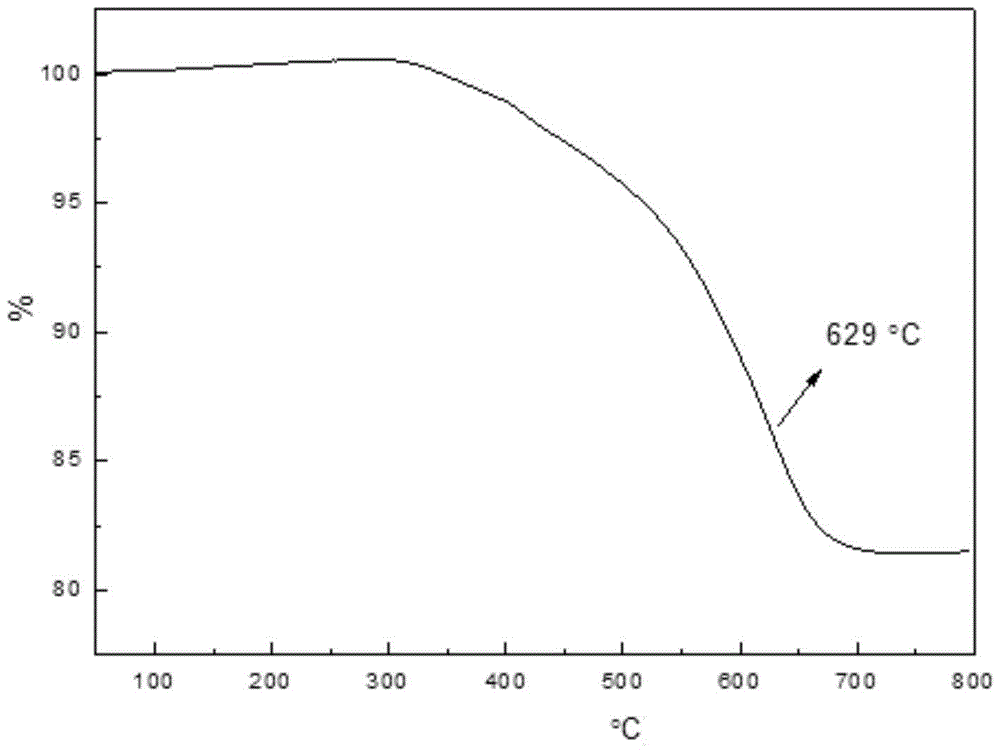

[0034] Using Nicolet Magna560 infrared spectrometer, operating at room temperature (25°C), the sample to be tested is ground together with KBr particles and then compre...

Embodiment 2

[0048] In a 250 mL four-necked flask, 15 g of phenyltriethoxy silane, 15 g of methyl trimethoxy silane, 0.2 g of potassium hydroxide, and 155 g of toluene were sequentially added. Then, 6ml of water was added dropwise for 12 minutes. After the addition, the temperature was raised to 65°C and refluxed for 12 hours. After the reaction, the solution was allowed to stand for layering. After the solution was cooled to room temperature, the white substance was filtered and the white product obtained Put it in a vacuum oven at a temperature of 150°C and a vacuum of -0.08MPa to dry for 5 hours to obtain a white powdery substance. The yield of silicone resin obtained by this method is 55%.

Embodiment 3

[0050] In a 250 mL four-necked flask were sequentially added 15 g of phenyltrimethoxysilane, 15 g of methyltriethoxysilane, 4 g of tetramethylammonium hydroxide, and 140 g of toluene. Then 10ml of water was added dropwise for 15 minutes. After the addition, the temperature was raised to 65°C and refluxed for 24 hours. After the reaction was completed, it was allowed to stand for layering. When the solution was cooled to room temperature, a white substance was obtained by filtering, and the white product obtained was placed Put it into a vacuum oven at a temperature of 150°C and a vacuum degree of -0.08MPa, and dry for 5 hours to obtain a white powdery substance. The yield of silicone resin obtained by this method is 75%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com