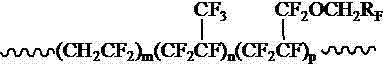

Low-temperature resistant fluorubber, and preparation method thereof

A fluororubber and low temperature resistant technology, applied in the field of low temperature resistant fluororubber and its preparation, can solve the problems of extremely high safety requirements, expensive raw materials, low brittle temperature, etc. The effect of improving low temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

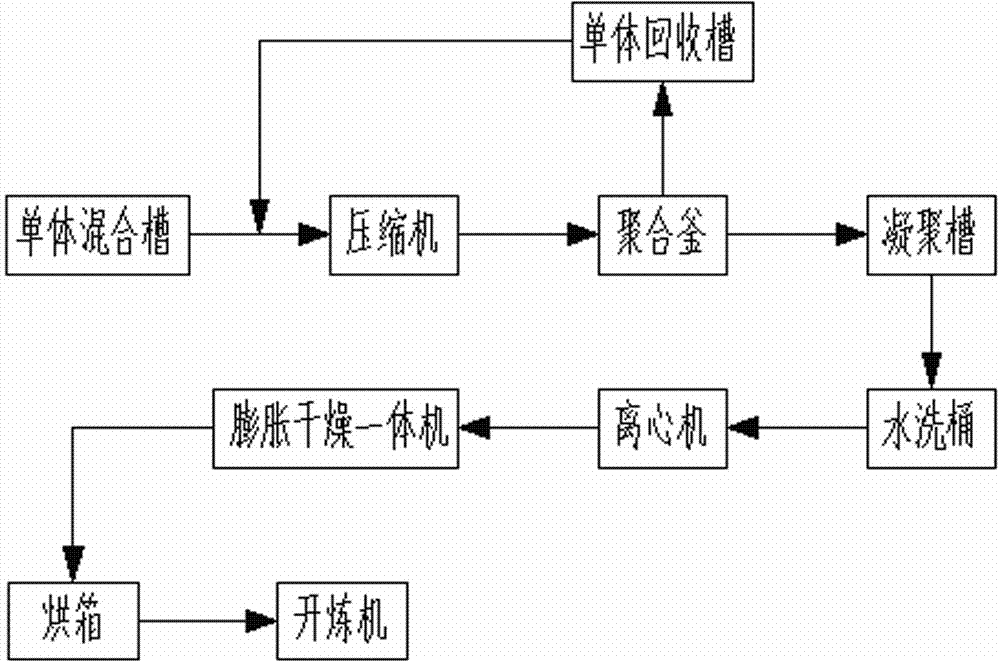

Method used

Image

Examples

Embodiment 1

[0017] In this embodiment, tetrafluoropropanol is used as raw material to prepare tetrafluoropropyl pentafluoropropenyl ether through condensation reaction:

[0018] In a reactor equipped with stirring, thermometer, and condenser, by weight, 24 parts of tetrafluoropropanol, 8 parts of pentafluorobromopropene and 1 part of tetrabutylammonium bromide were dissolved in 20 parts of CH 2 Cl 2 Add 7.5 parts of aqueous solution of 5 parts of NaOH dropwise, heat up to 50°C and react for 24 hours, cool the reaction solution, filter out insoluble salts, separate the oil layer, pickle with 4% hydrochloric acid once, wash with distilled water 3 times to medium properties, after drying with anhydrous sodium sulfate, the product tetrafluoropropyl pentafluoropropenyl ether was obtained by fractional distillation with a yield of 83.5%.

[0019] Re-synthesis of branched fluorine rubber containing tetrafluoropropyl pentafluoropropenyl ether:

[0020] to 3m 3 Add 1500Kg of deionized water to ...

Embodiment 2

[0022] In this example, octafluoropentyl pentafluoropropenyl ether was prepared by condensation reaction according to the preparation method of Example 1, and the yield was 76.4%.

[0023] Re-synthesis of branched fluorine rubber containing octafluoropentyl pentafluoropropenyl ether:

[0024] to 3m 3 Add 1500Kg of deionized water to the polymerization kettle, replace with nitrogen and vacuumize, and then add 0.9Kg of ammonium perfluorooctanoate, 1.5Kg of disodium hydrogen phosphate, and 7.5Kg of diethyl malonate into the polymerization kettle after the oxygen content in the kettle is qualified. Then, a monomer mixture composed of 1,1-difluoroethylene, hexafluoropropylene, and octafluoropentylpentafluoropropenyl ether in a molar ratio of 75:22:3 is added into the reaction kettle through a compressor to make the pressure in the kettle When it reaches 2.0Mpa, heat the reaction mixture to 85°C, add 0.9Kg potassium persulfate to start the reaction, and continuously add monomer mix...

Embodiment 3

[0026] to 3m3 Add 1500Kg of deionized water into the polymerization kettle, replace with nitrogen and vacuumize, and after the oxygen content in the kettle is qualified, add 12Kg of ammonium perfluorooctanoate, 6Kg of disodium hydrogen phosphate, and 3Kg of diethyl malonate into the polymerization kettle, and then add 1 , 1- difluoroethylene, hexafluoropropylene, tetrafluoropropyl pentafluoropropenyl ether in a molar ratio of 78:12:10 into the reaction kettle through the compressor, so that the pressure in the kettle reaches 2.4Mpa , the reaction mixture was heated to 75°C, and 1.5Kg potassium persulfate was added to start the reaction. During the reaction, the monomer mixture was continuously added to keep the pressure at 2.6Mpa, while maintaining a stirring rate of 500r / min to maintain the reaction rate; Finally, stop adding the monomer mixture, and recover the unreacted mixed monomer after cooling; the latex obtained by polymerization is coagulated, washed, dried and dehydra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com