Crystal form of warnemulin tartrate and preparation method thereof

A technology for crystal form of nimulin and tartaric acid, which is applied in the field of new crystal form of vornimulin tartrate and its preparation, can solve the problems of unfavorable use of premix, XRD peak strength, low crystallinity and the like, and achieves good fluidity, crystallinity and the like. The effect of uniform particle size distribution and high crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

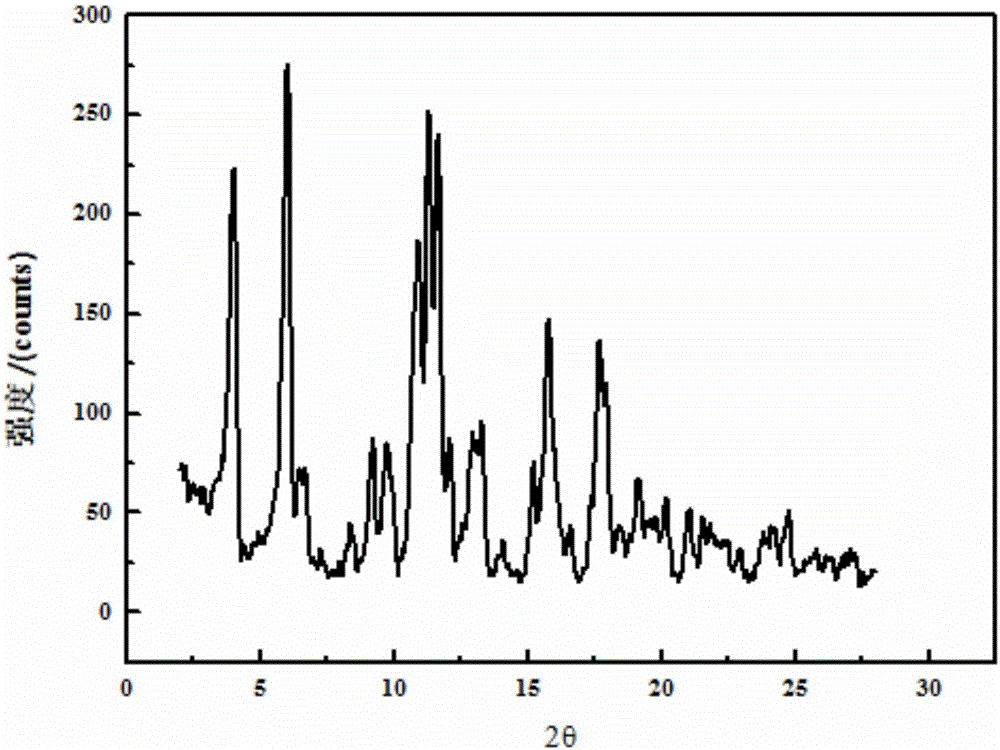

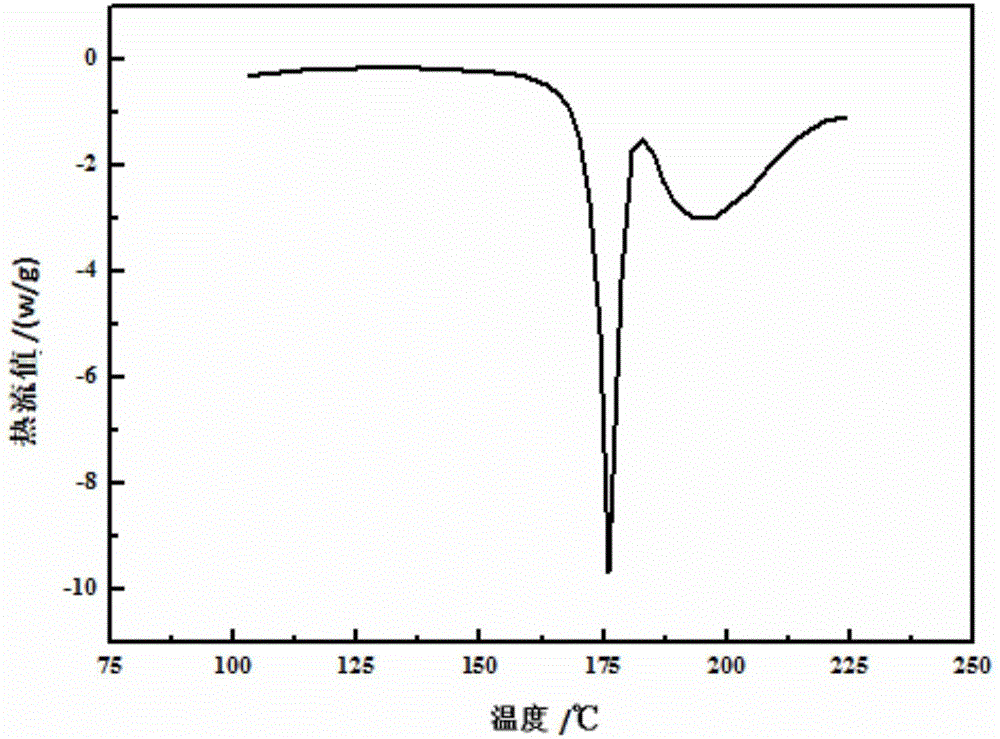

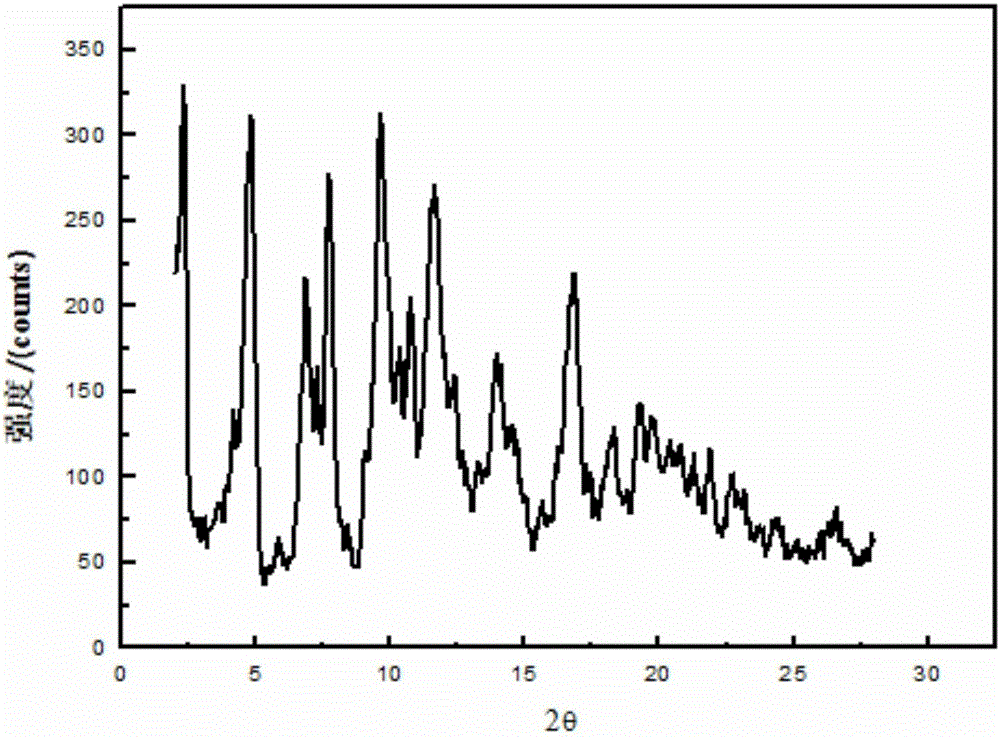

[0030] Add 5g of warnemulin tartrate with a purity of 98% to a crystallizer filled with 10mL of N,N-dimethylformamide and 90mL of methyl acetate mixed solvent, stir at 50°C until completely dissolved, and then drop into 100mL of methyl acetate eluent was used for elution and crystallization, and the dropping rate was 0.5mL / min. Then conduct cooling crystallization at a cooling rate of 10°C / h, lower the temperature to 10°C, stir and grow the crystal for 1 hour, carry out suction filtration and washing, and dry the filter cake at 20°C and a vacuum degree of 0.08MPa for 24 hours to obtain the new crystal form of vornimulin tartrate . The process mass yield is 91.5%, the crystal particle size is 15 μm, and the purity is 98.5%. The XRD pattern of the obtained product has characteristic peaks at diffraction angles 2θ=2.48, 4.85, 7.41, 7.53, 10.01, 11.21, 11.70, 13.82 and 17.12 degrees, and the DSC pattern There is a characteristic peak at 101.2°C. The product has good water solubi...

Embodiment 2

[0032] Add 6g of warnemulin tartrate with a purity of 96% to a crystallizer filled with 15mL of N,N-dimethylformamide and 85mL of ethyl acetate mixed solvent, stir at 40°C until completely dissolved, and then drop into Ethyl acetate dissolution agent 150mL was dissolved and crystallized, and the dropping rate was 1.5mL / min. Then carry out cooling and crystallization at a cooling rate of 3°C / h, lower the temperature to 15°C, stir and grow the crystal for 2h, carry out suction filtration and washing, and dry the filter cake at 30°C and vacuum degree of 0.04MPa for 12h to obtain the new crystal form product of vornimulin tartrate . The process mass yield is 92.0%, the crystal particle size is 18 μm, and the purity is 99.0%. The XRD pattern of the obtained product has characteristic peaks at diffraction angles 2θ=2.45, 4.83, 7.41, 7.43, 10.01, 11.28, 11.65, 13.85 and 17.18 degrees, and the DSC pattern There is a characteristic peak at 102.3°C. The product has good water solubili...

Embodiment 3

[0034]Add 7g of warnemulin tartrate with a purity of 97% to a crystallizer filled with a mixed solvent of 15mL N,N-dimethylformamide and 85mL butyl acetate, stir at a constant temperature at 50°C until it dissolves completely, and then drop into 200mL of butyl acetate eluent was used for elution and crystallization, and the dropping rate was 4mL / min. Then carry out cooling and crystallization at a cooling rate of 12°C / h, lower the temperature to 5°C, stir and grow the crystal for 1 hour, carry out suction filtration and washing, and dry the filter cake at 20°C and a vacuum degree of 0.06MPa for 18 hours to obtain a new crystal form product of vornimulin tartrate . The process quality yield is 93.5%, the crystal particle size is 20 μm, and the purity is 98.7%. The XRD pattern of the obtained product has characteristic peaks at diffraction angles 2θ=2.44, 4.87, 7.48, 7.56, 10.05, 11.27, 11.72, 13.84 and 17.13 degrees, and the DSC pattern There is a characteristic peak at 100.7°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com