Method of preparing foamed air brick by taking iron tailings as main material

A technology for iron tailings and hollow bricks is applied in the preparation of hollow bricks and in the field of foamed hollow bricks, which can solve the problems of serious natural environment and destroy ecological balance, and achieve the effects of reducing consumption, good thermal insulation performance and light weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

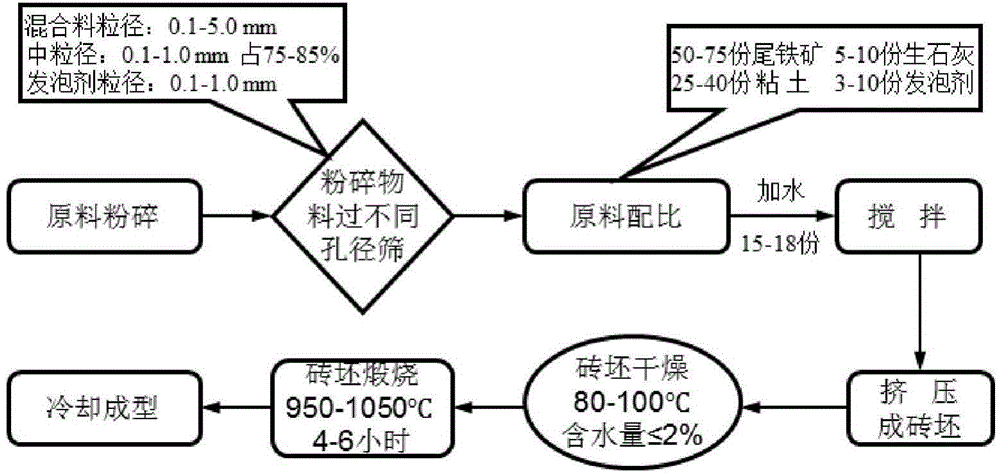

Method used

Image

Examples

Embodiment 1

[0022] Crush 58 parts by mass of iron tailings, 30 parts by mass of clay, 7 parts by mass of quicklime and 5 parts by mass of foaming agent and mix them according to the proportion to obtain a mixture. Add 16 parts by mass of water to the mixture and stir evenly to obtain a foamed hollow brick The bricks are dried at 80-100°C to a moisture content ≤2%, then calcined and foamed at 1050°C for 6 hours, and cooled to form a foamed hollow brick.

[0023] During the calcination and foaming process, the heating time to 500-600℃ is 4 hours, the decomposition of pyrite and siderite produces an exothermic peak, resulting in 6-8% thermogravimetric loss; when the temperature rises to 750-830℃ , The endothermic reaction slows down the heating rate, and the time for heating to this temperature range is controlled within 2-3 hours.

[0024] The foaming agent is composed of sodium carbonate, fly ash and expanded perlite, and the mass ratio is (0.3-0.5):1:(1-2). The particle size of the foaming ag...

Embodiment 2

[0027] Crush 60 parts by mass of iron tailings, 28 parts by mass of clay, 7 parts by mass of quicklime and 5 parts by mass of foaming agent and mix them according to the proportion to obtain a mixture. Add 15 parts by mass of water to the mixture and stir evenly to obtain a foamed hollow brick The bricks are dried at 80-100°C until the moisture content is ≤2%, then calcined and foamed at 1050°C for 5 hours, and cooled to form a foamed hollow brick. Other preparation parameters are the same as in Example 1.

[0028] According to GB / T5101-2003 "Ordinary Sintered Bricks", GB13544-2011 "Sintered Perforated Bricks", GB13545-2003 "Hollow Bricks and Hollow Bricklaying" and GB6566-2010 "Limits of Radionuclide for Building Materials", the prepared development The foamed hollow brick products are tested for compressive strength, durability and radioactivity. Compressive strength test result: average value is 10.7MPa, average value standard is ≥10MPa, minimum value is 8.9MPa, minimum value...

Embodiment 3

[0030] Crush 62 parts by mass of iron tailings, 28 parts by mass of clay, 6 parts by mass of quicklime and 4 parts by mass of foaming agent and mix them according to the proportion to obtain a mixture. Add 18 parts by mass of water to the mixture and stir to obtain a foamed hollow brick. The bricks are dried at 80-100°C to a moisture content ≤2%, then calcined and foamed at 1000°C for 6 hours, and cooled to form a foamed hollow brick. Other preparation parameters are the same as in Example 1.

[0031] According to GB / T5101-2003 "Ordinary Sintered Bricks", GB13544-2011 "Sintered Perforated Bricks", GB13545-2003 "Hollow Bricks and Hollow Bricklaying" and GB6566-2010 "Limits of Radionuclide for Building Materials", the prepared development The foamed hollow brick products are tested for compressive strength, durability and radioactivity. Compressive strength test results: average value is 11.0MPa, average value standard is ≥10MPa, minimum value is 9.1MPa, minimum value standard is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com