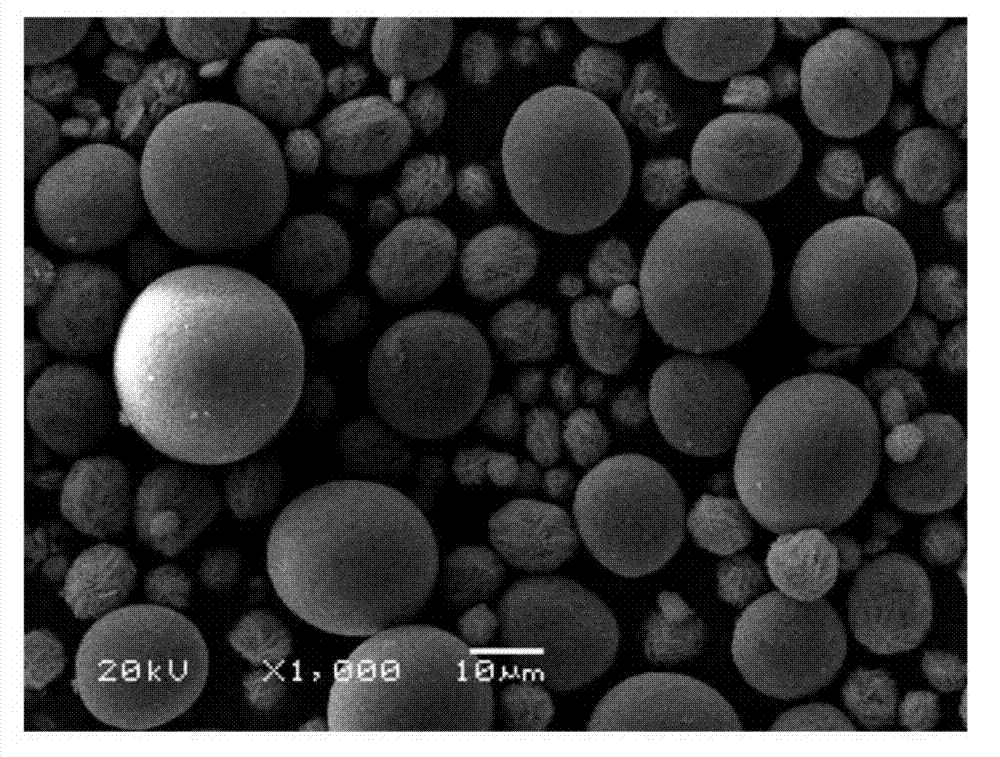

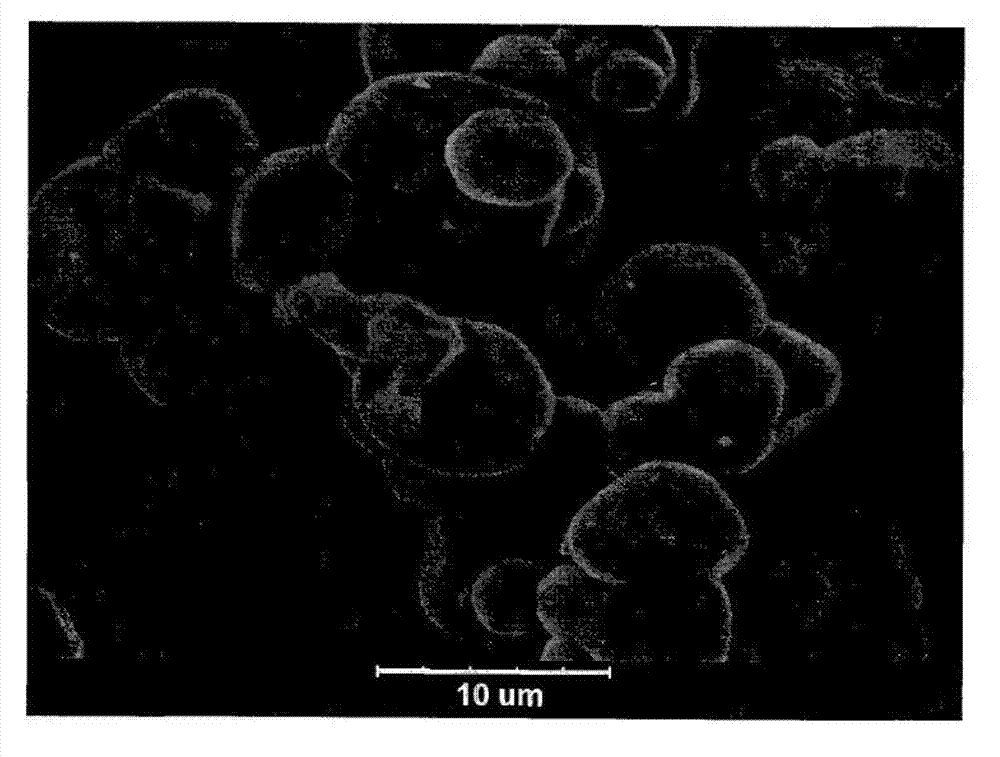

Preparation method of large-particle spherical cobaltosic oxide

A technology of tricobalt tetroxide and large particles, which is applied in the direction of cobalt oxide/cobalt hydroxide, etc., can solve the problems of insufficient sphericity, reaction, and low energy density of lithium-ion secondary batteries, so as to improve energy density, performance, and energy density high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Prepare 1.0mol / L cobalt sulfate (CoSO 4 ) aqueous solution;

[0028] (2) Prepare 4.0mol / L sodium hydroxide aqueous solution;

[0029] (3) Prepare a mixed solution of ethylenediamine and hydrazine hydrate with deionized water, and the mixed solution contains 0.3mol / L ethylenediamine and 0.05mol / L hydrazine hydrate;

[0030] (4) The above cobalt sulfate (CoSO 4 ) solution, sodium hydroxide solution and mixed solution were added to the reaction kettle at a flow rate of 250L / h, 100L / h and 50L / h respectively, the reaction temperature was controlled at 40°C, the reaction pH was 9, and the stirring speed was 700rpm / min, react for 12h to prepare the precursor;

[0031] (5) The above precursor was washed with deionized water, filtered, and then calcined at 800°C for 6 hours to obtain tricobalt tetroxide A.

Embodiment 2

[0033] (1) Prepare 1.0mol / L cobalt chloride (CoCl 2 ) aqueous solution;

[0034] (2) Prepare 5.0mol / L sodium hydroxide aqueous solution;

[0035] (3) Prepare a mixed solution of EDTA and sodium thiosulfate with deionized water, the mixed solution contains 0.5mol / L of EDTA and 0.1mol / L of sodium thiosulfate;

[0036] (4) The above cobalt chloride (CoCl 2 ) solution, potassium hydroxide solution and mixed solution were added to the reaction kettle at a flow rate of 150L / h, 150L / h and 40L / h respectively, the reaction temperature was controlled at 50°C, the reaction pH was 10, and the stirring speed was 900rpm / min, reacted for 13h to prepare the precursor;

[0037] (5) The above precursor was washed with deionized water, filtered, and then calcined at 800°C for 5 hours to obtain tricobalt tetroxide B.

Embodiment 3

[0039] (1) Prepare 2.0mol / L cobalt sulfate (CoSO 4 ) aqueous solution;

[0040] (2) Prepare 6.0mol / L potassium hydroxide aqueous solution;

[0041] (3) Prepare tartaric acid and hydrazine hydrate with deionized water to prepare a mixed solution containing 1.0 mol / L tartaric acid and 0.15 mol / L hydrazine hydrate;

[0042] (4) The above cobalt sulfate (CoSO 4 ) solution, potassium hydroxide solution and mixed solution were added to the reaction kettle at a flow rate of 100L / h, 120L / h and 30L / h respectively, the reaction temperature was controlled at 60°C, the reaction pH was 11, and the stirring speed was 1000rpm / min, react for 14h to prepare the precursor;

[0043](5) The above precursor was washed with deionized water, filtered, and then calcined at 700°C for 4 hours to obtain tricobalt tetroxide C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com