A method for reducing sulfate radical content in dihydrate dilute phosphoric acid

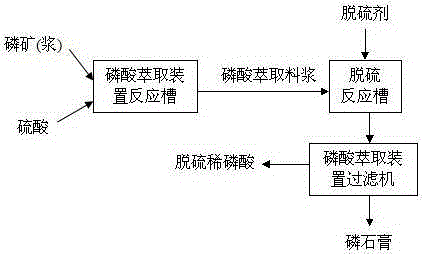

A technology of sulfate radical and dilute phosphoric acid, applied in the field of phosphoric acid, can solve the problems of long desulfurization time, high phosphorus residue in filter residues, difficult to handle, etc., and achieve the effect of good desulfurization effect, short desulfurization reaction time and fast reaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 10 tons of wet-process phosphoric acid extraction slurry that has completed the phosphoric acid extraction reaction obtained by the dihydric wet-process phosphoric acid process has a liquid phase mass of 7.1t, and a liquid phase sulfate radical mass percentage of 3.0%. Add 395 kg of desulfurizer (fertilizer grade calcium hydrogen phosphate) with a phosphorus content of 13% and a calcium content of 22%, that is, the mass ratio of the calcium content in the desulfurizer to the sulfate radical in the slurry phase of the wet-process phosphoric acid extraction material is about 0.41:1 , the desulfurizer is added to the phosphoric acid extraction slurry, mixed and stirred at 75°C for 20 minutes, and then the mixed slurry is sent to the filter of the phosphoric acid extraction device for filtration, and dilute phosphoric acid is obtained by filtration, and the mass percentage of sulfate radicals in dilute phosphoric acid is 0.6 %.

Embodiment 2

[0021] 8 tons of wet-process phosphoric acid extraction slurry that has completed the phosphoric acid extraction reaction obtained by the dihydric wet-process phosphoric acid process, its liquid phase quality is 5.5t, and the mass percentage content of liquid phase sulfate is 4.5%, in this phosphoric acid extraction slurry Add 310kg of desulfurizer (fertilizer grade calcium hydrogen phosphate) with a phosphorus content of 10% and a calcium content of 28%, that is, the mass ratio of the calcium content in the desulfurizer to the sulfate radical in the slurry phase of the wet-process phosphoric acid extraction material is about 0.35:1 , the desulfurizer is added to the phosphoric acid extraction slurry, mixed and stirred at 80°C for 5 minutes, and then the mixed slurry is sent to the filter of the phosphoric acid extraction device for filtration, and the diluted phosphoric acid is obtained by filtration. The mass percentage of sulfate radicals in the diluted phosphoric acid is 1.1...

Embodiment 3

[0023] 15 tons of wet-process phosphoric acid extraction slurry obtained by the dihydric wet-process phosphoric acid process has completed the phosphoric acid extraction reaction, its liquid phase quality is 11t, and the liquid phase sulfate radical mass percentage is 1.8%. In this phosphoric acid extraction slurry Add 550kg of desulfurizer (fertilizer grade calcium hydrogen phosphate) with a phosphorus content of 17% and a calcium content of 18%, that is, the mass ratio of the calcium content in the desulfurizer to the sulfate radical in the slurry phase of the wet-process phosphoric acid extraction material is about 0.50:1, After the desulfurizer is added to the phosphoric acid extraction slurry, mix and stir at 60°C for 30 minutes, then send the mixed slurry to the filter of the phosphoric acid extraction device for filtration, and filter to obtain dilute phosphoric acid. The mass percentage of sulfate radicals in dilute phosphoric acid is 0.2% .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com