Ash sealing device for preventing low-temperature gas from entering high-temperature dust remover

A technology of high-temperature dust collector and low-temperature gas, which is applied in the direction of devices whose axial direction can be reversed, swirl devices, chemical instruments and methods, etc., which can solve the problems of poor closing effect of valves, difficulties in effective implementation, and incomplete elimination To achieve the effect of preventing low-temperature gas from entering the dust collector, improving the promotion and use value, and improving the utilization rate of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

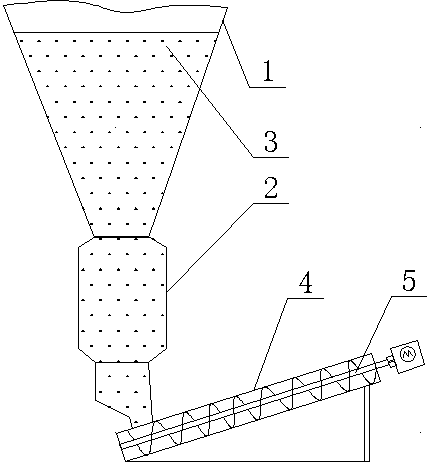

[0024] Such as figure 1 As shown, an ash sealing device for preventing low-temperature gas from entering a high-temperature dust collector includes an ash hopper 1 of the dust collector arranged up and down, an ash unloading chamber 2 and an ash conveying device, and an ash column 3 of a certain height is maintained in the ash hopper 1 ; The ash conveying device includes the ash conveying pipeline 4 and the ash removing mechanism in the ash conveying pipeline 4, wherein the ash removing mechanism is a spiral push mechanism 5, and the ash conveying pipeline 4 is arranged as an inclined straight line, and the inclination angle is 0 ~30°.

Embodiment 2

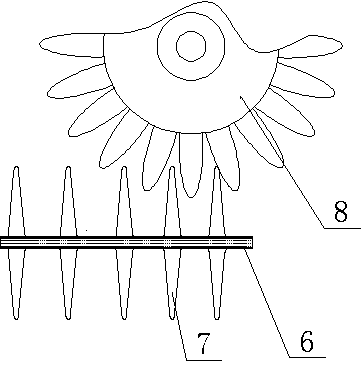

[0026] Such as figure 2 As shown, the difference from Embodiment 1 is that: the ash conveying pipeline 4 is arranged in a ring shape, and the ash cleaning mechanism is a dust scraper, and the dust scraper includes a driving device, a soft belt 6 and a belt on the soft belt 6 A plurality of scraper blades 7 are provided, and the scraper blades 7 are arranged as annular blades, the output end of the driving device is provided with a transmission member 8 connected to the scraper blades 7, and the ash inlet of the ring-shaped ash conveying device is at a low position.

Embodiment 3

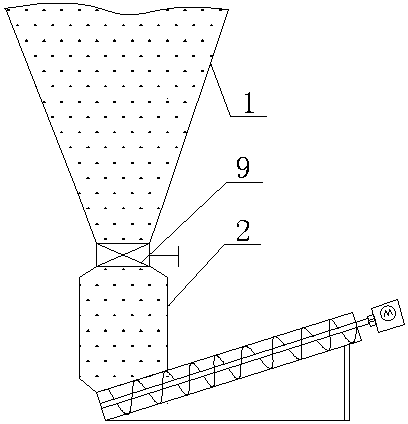

[0028] Such as image 3 As shown, the difference from Embodiment 1 or 2 is that a sealing valve 9 is provided between the ash hopper 1 and the ash discharge chamber 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com