Polylactic acid-chitosan composite nerve conduit and preparation method thereof

A nerve conduit and chitosan technology, which is applied in the field of medical biomaterials, can solve the problems of regeneration and repair of unfavorable axon damage, affecting regeneration and repair of defective nerves, and low mechanical strength of nerve conduits, so as to avoid immune rejection and infectious diseases, The effect of repairing peripheral nerve defects and easy control of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Embodiment 1: Preparation of polylactic acid / chitosan composite nerve guide

[0059] (1) Dissolve 0.8 g of polylactic acid in 10 ml of hexafluoroisopropanol and stir overnight at room temperature to form a uniform and stable solution.

[0060] (2) Put the polylactic acid solution into the syringe, and connect the needle of the syringe to a high-voltage power supply. The solution supply flow is controlled at 5ml / h by a microflow pump, the applied voltage is 15kv, the distance between the high voltage end and the ground end is 15cm, the diameter of the roller used is 8cm, and the rotation speed is 3000rpm. Through this process, a polylactic acid nanofiber membrane with a diameter of about 630 nm and a thickness of about 0.2 mm can be collected.

[0061] (3) Immerse the polylactic acid nanofibrous membrane in dilute acetic acid solutions of chitosan with a concentration of 0.2%, 0.4% and 0.6% respectively (the number average molecular weight of chitosan is 500,000, the de...

Embodiment 2

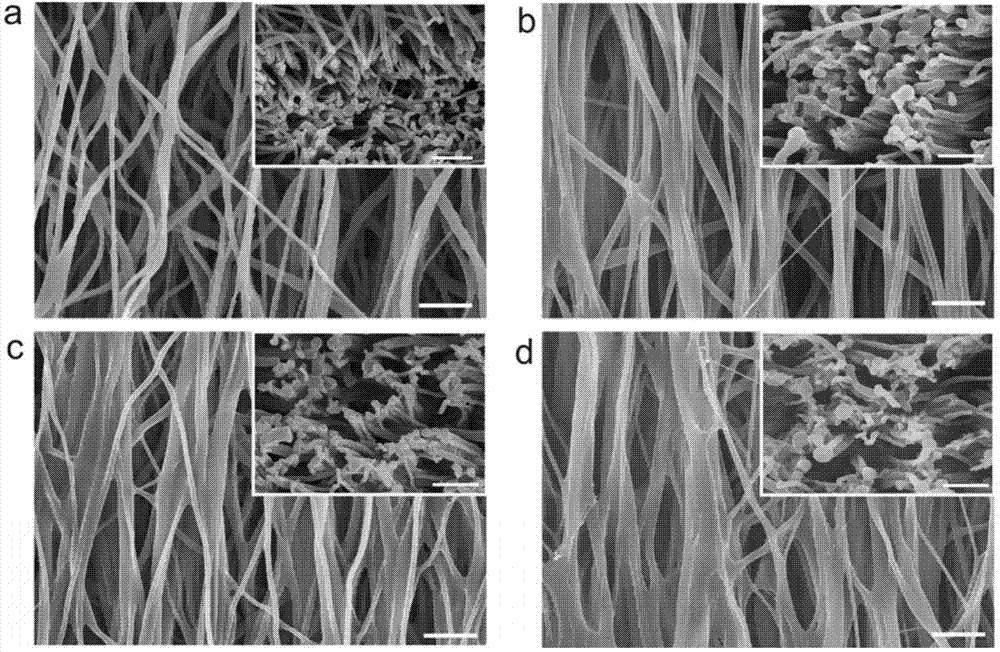

[0064] Embodiment 2: Observation of microscopic morphology of polylactic acid / chitosan composite nerve conduit

[0065] The surface and cross-sectional morphology of polylactic acid / chitosan composite nerve conduits with different chitosan compounding amounts were analyzed by field emission scanning electron microscope (JSM-6700F, JEOL, Japan), and the accelerating voltage was 10kV.

[0066] The result is as figure 2 As shown, it can be seen that pure polylactic acid ( figure 2 a) and polylactic acid / chitosan composite fiber ( figure 2 b, c, d) are all highly oriented and arranged; there is no chitosan wrapping on the surface of pure polylactic acid fiber, the pore size is large, and the porosity is high; with the increase of chitosan compounding amount, chitosan wrapping can be clearly observed On the surface of PLA fibers and in the voids between fibers, the porosity decreased gradually. It can be seen from the cross-sectional morphology that the pure polylactic acid f...

Embodiment 3

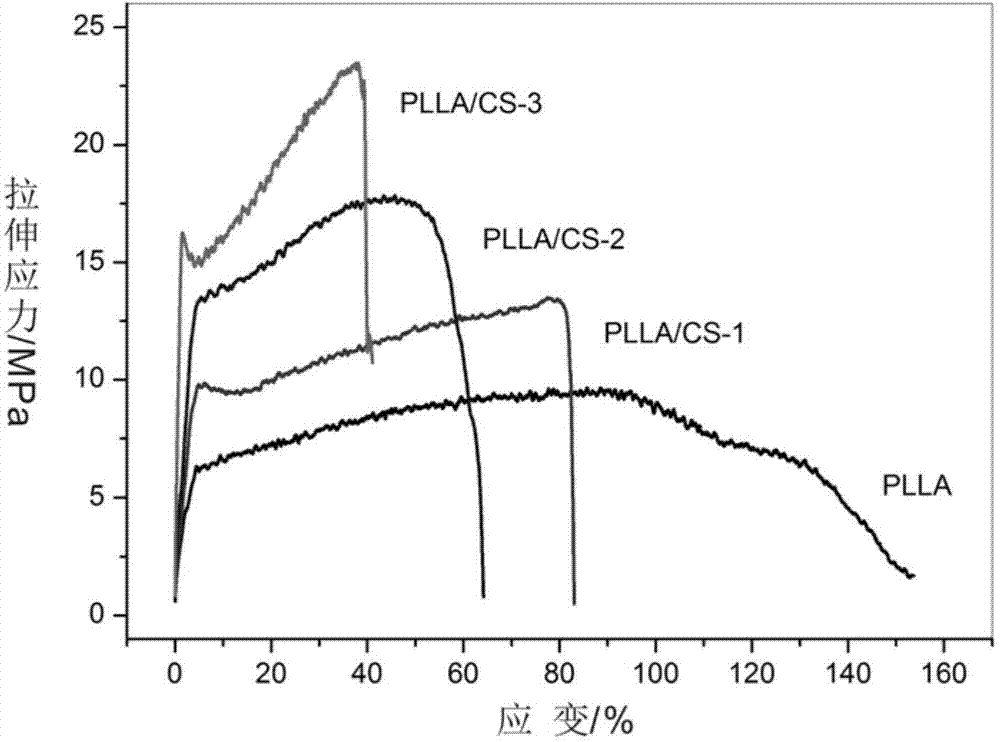

[0067] Embodiment 3: Research on the biomechanical properties of polylactic acid / chitosan composite nerve guide

[0068] Cut the polylactic acid / chitosan composite fiber membrane into a sample with a length and width of 40×4mm, trim the two sides of the sample flat to prevent cracks, and then use a spiral micrometer to measure the thickness of each sample, and select different parts Measure three times and take the average value. Then, the tensile mechanical properties were measured by a universal mechanical testing machine, and the rising speed of the crosshead was 2mm / min. The polylactic acid / chitosan composite nerve guide is placed horizontally on the test bench, and the anti-pressure performance is measured by a universal mechanical testing machine. The descending speed of the crosshead is 0.5mm / min.

[0069] The results showed that the tensile strength of polylactic acid / chitosan composite fiber membrane was significantly higher than that of pure polylactic acid fiber, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Aperture size | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com