Axial magnetic flow modularized multi-phase motor having high magnetic isolation capacity

A technology of isolation capability and axial flux, applied to synchronous motors with stationary armatures and rotating magnets, etc., can solve the problems of difficult fault-tolerant control, unfavorable fault isolation design into a modular structure, etc., to achieve convenient large-scale Processing and manufacturing, manufacturing and maintenance costs are low, and the effect of improving power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

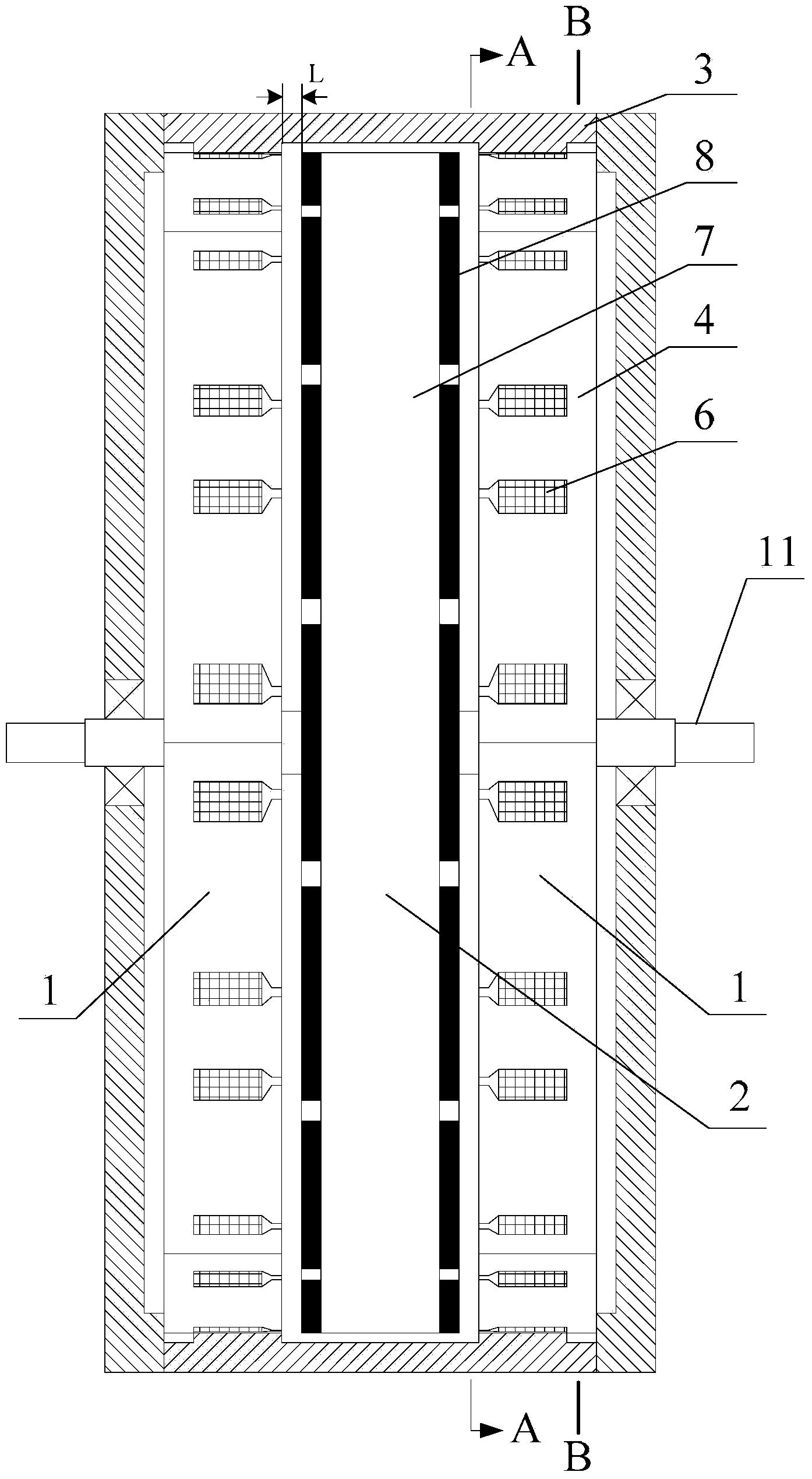

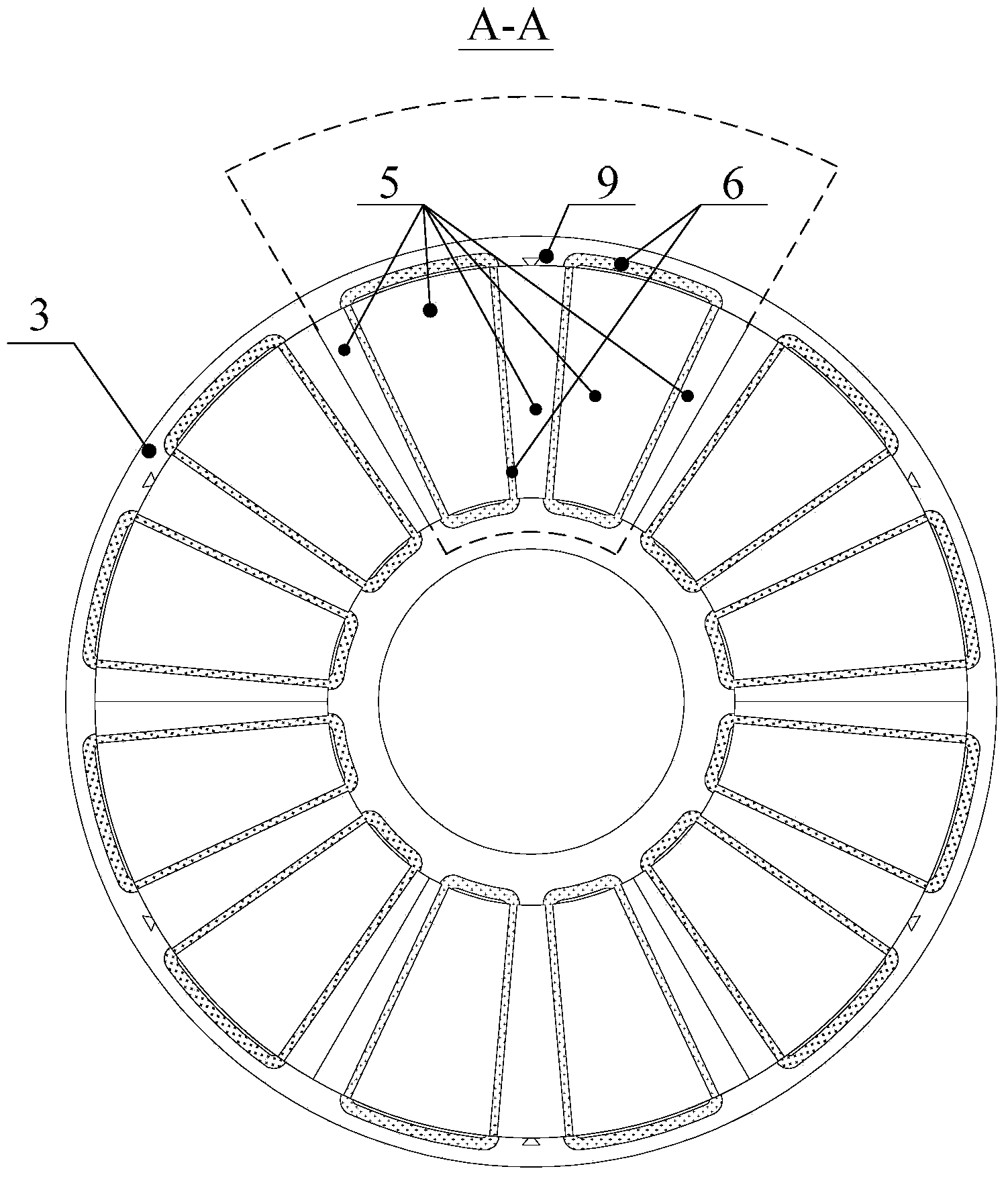

[0021] Specific implementation mode one: the following combination Figure 1 to Figure 11 This embodiment is described. The axial flux modular multiphase motor with high magnetic isolation capability described in this embodiment includes two modular stators 1, a disc rotor 2, a casing 3 and a main shaft 11. Two modules A modular stator 1 and a disc rotor 2 are arranged inside the casing 3; a modular stator 1, a disc rotor 2 and another modular stator 1 are arranged on the main shaft 11 in sequence along the axial direction; two modular stators 1 and the disc There is an air gap between the rotors 2 in the axial direction, and the length of the air gap is L;

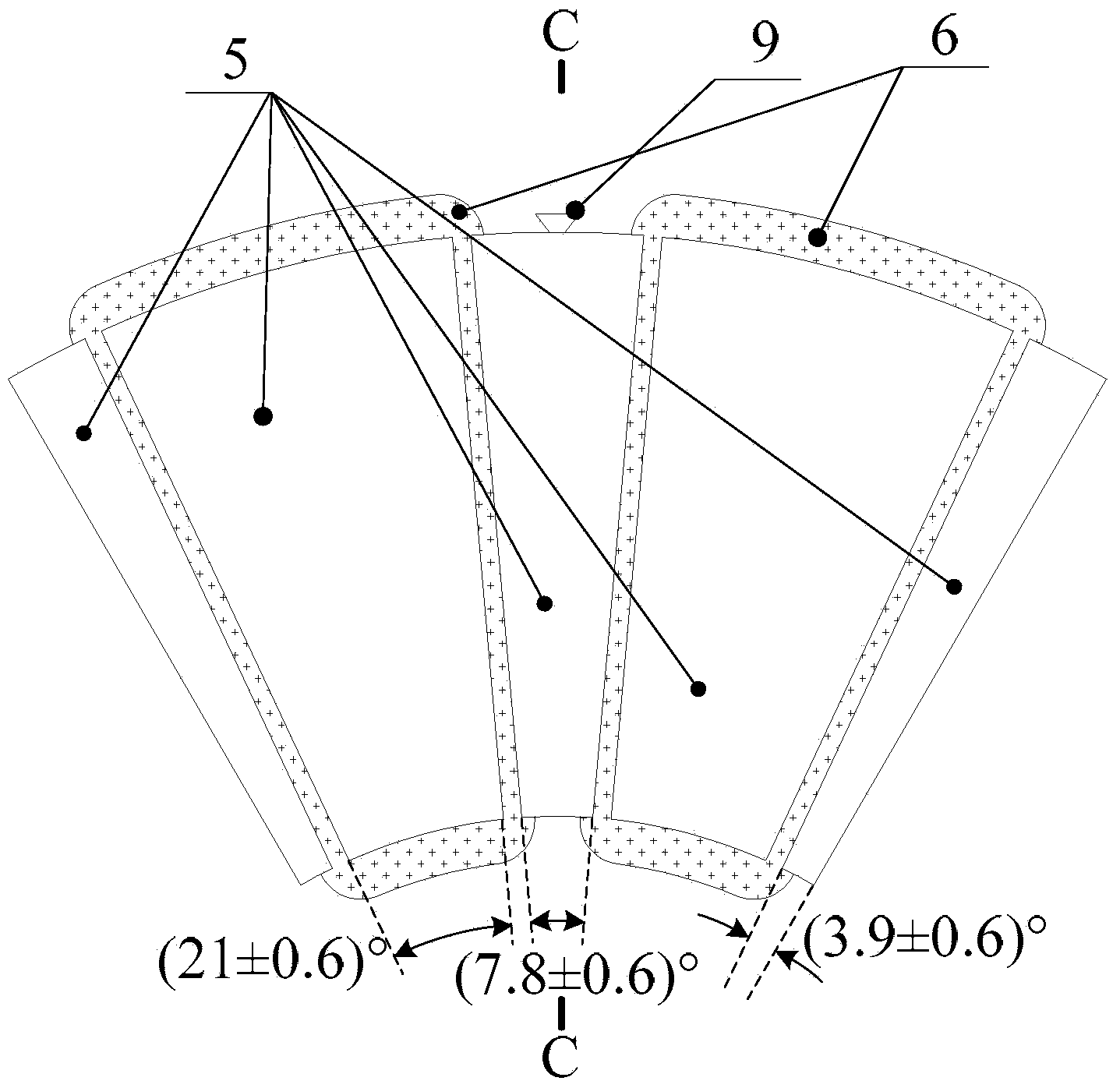

[0022] Each modular stator 1 includes N identical stator modules, and the N identical stator modules are spliced into a disc shape; each stator module includes a stator core 4, five stator teeth 5 and two concentrated windings 6. Five stator teeth 5 are set on the stator core 4; the included angles of the sectors where...

specific Embodiment approach 2

[0039] Specific implementation mode two: the following combination figure 2 , image 3 , Figure 5 and Figure 8 This embodiment will be described. This embodiment will further describe Embodiment 1. A wedge-shaped piece 9 is processed on the stator yoke where the stator teeth 5 with an angle of [360×(0.13±0.01) / N]° of each stator module are located. N dovetail grooves 10 are arranged on the inner circular surface of the casing 3 , and the wedge-shaped piece 9 cooperates with the dovetail grooves 10 to be fixed.

[0040] The N stator modules adopt a detachable structure during processing and installation.

[0041]It is necessary to process a wedge 9 on the yoke of each stator module, and open a dovetail groove 10 on the casing 3. The inner diameter of the casing 3 is equal to the outer diameter of the modular stator 1. The two adopt clearance fit, and the N stator modules Nested in the casing 3.

specific Embodiment approach 3

[0042] Embodiment 3: In this embodiment, Embodiment 1 is further described. Both the stator core 4 and the rotor core 7 are made of soft magnetic composite materials.

[0043] It is convenient for processing and manufacturing, and reduces eddy current loss.

[0044] When the stator module is processed, it can be molded at one time using soft magnetic composite materials. This implementation mode has simple procedures, can increase the speed of processing and manufacturing, and is beneficial to mass production.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com