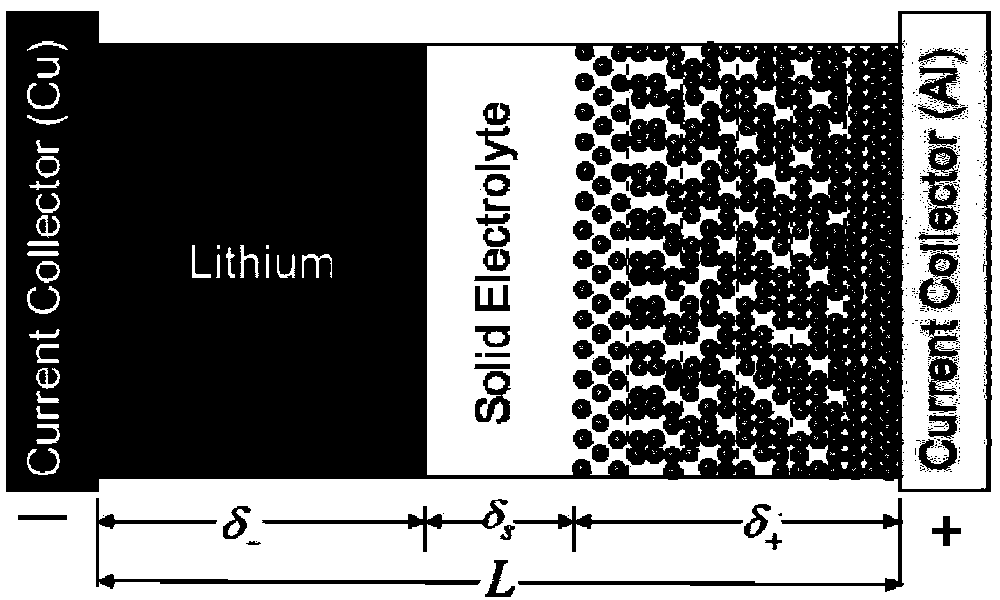

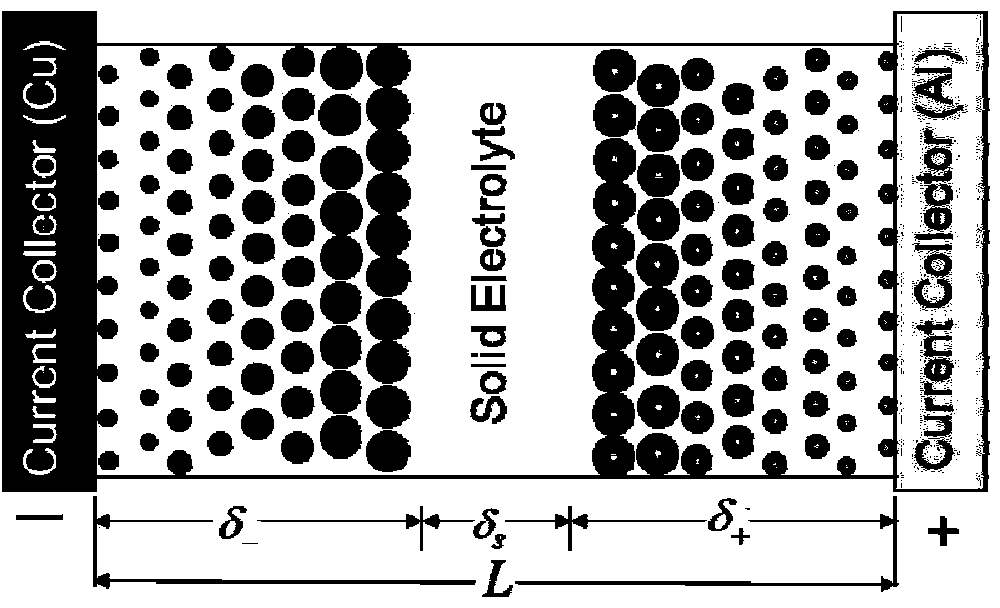

All-solid-state lithium battery with gradient structure and preparation method thereof

A gradient structure, all-solid-state technology, applied in the manufacture of electrolyte batteries, secondary batteries, battery electrodes, etc., can solve the problems of easy depletion of Li ions, large interface impedance, and easy deterioration of electrodes and electrolytes, and achieves improved diffusion rate. , to achieve the effect of contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

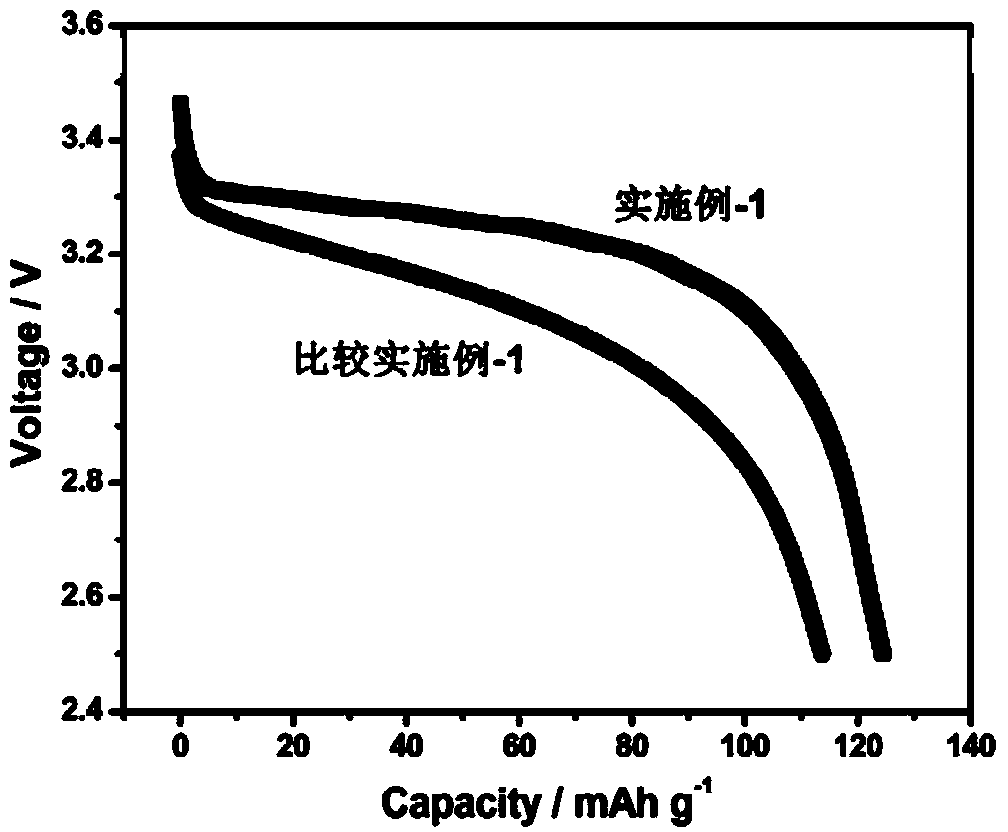

Embodiment 1

[0038] (a) Change the amount of the electrode material and solid electrolyte to be added to form the electrode layer so that the mass fraction of the electrode material is 10%, 50%, and 100%, and prepare a positive electrode slurry. The electrode material is LiFePO 4, a mixture of polyvinylidene fluoride and conductive carbon (mass ratio 8:1:1), the electrolyte is a mixture of polysiloxane and lithium salt (mass ratio 8:2), and the slurry has a viscosity of 3cP at room temperature;

[0039] (b) Coating the collector electrode with the various positive electrode slurries, so that the concentration gradient of the positive electrode material decreases sequentially from the collector electrode of the electrode active material layer to the surface of the positive electrode layer, thereby stacking multiple positive electrode thin film layers with different solid concentrations; each The thickness of each positive film layer is about 50 μm;

[0040] (c) Configure the electrolyte sl...

Embodiment 2

[0048] (a) Mixing a certain amount of spinel structure LiMn 2 o 4 It is a positive electrode active material, a certain amount of acetylene black is used as a conductive material, a certain amount of polyvinylidene fluoride is used as a binder, and the mass ratio of the three is 9:5:5, and a certain amount of polysiloxane and lithium salt, The ratio of the two is 8:2, so that the mass ratio of the electrolyte component to the electrode material is maintained at 7:3, changing the LiMn 2 o 4 particle size (0.1μm, 0.3μm, 0.6μm), so as to prepare a variety of cathode slurries with different particle sizes of active materials;

[0049] (b) Coating the collector electrode with the various positive electrode slurries, so that the particle size of the positive electrode active material increases sequentially from the collector electrode of the electrode active material layer to the surface of the positive electrode layer, and the thickness of each positive electrode film layer is ab...

Embodiment 3

[0055] (a) Mixing a certain amount of LiCoO 2 A certain amount of acetylene black is used as a conductive material, a certain amount of polyvinylidene fluoride is used as a binder, and the mass ratio of the three is 9:5:5. A certain amount of polyoxyethylene and lithium salt, two The ratio is 8:2, so that the mass ratio of the electrolyte component to the electrode material is maintained at 7:3, and the molecular weight of the polyoxyethylene is changed (8000, 400000, 4000000), so that the molecular weight of the prepared electrolyte polymer is much different A positive electrode slurry;

[0056] (b) Coating the collector with the various positive electrode slurries, so that the molecular weight of polyoxyethylene increases sequentially from the collector to the surface of the positive electrode layer, and the thickness of each positive electrode film layer is about 50 μm;

[0057] (c) Configure electrolyte slurry, polyoxyethylene (molecular weight: 4,000,000) and lithium sal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com