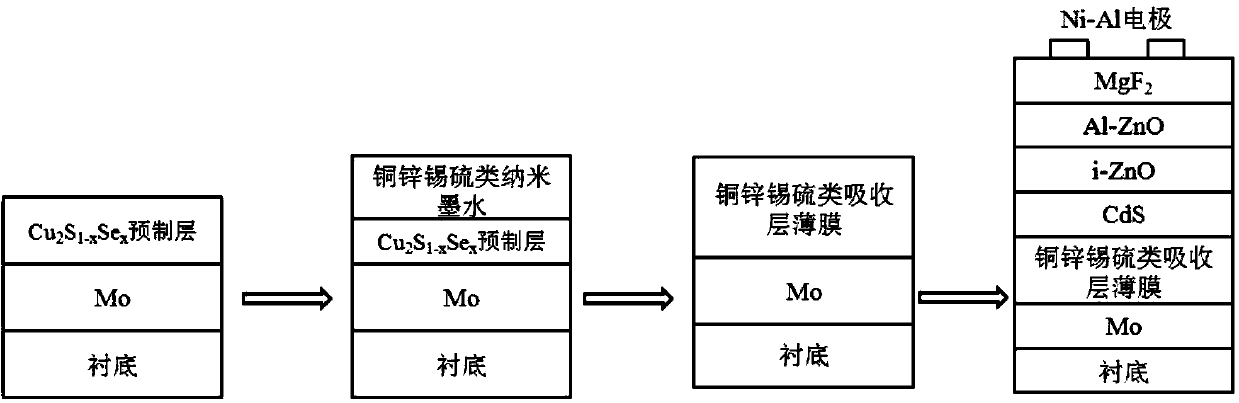

Method for preparing copper-zinc-tin-sulfur thin-film solar cell through interfacial modification

A technology of solar cells and copper-zinc-tin-sulfur, applied in the field of solar energy, can solve the problems of rough and uneven film formation, poor crystallinity, poor adhesion of Mo back contact layer, etc. Strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

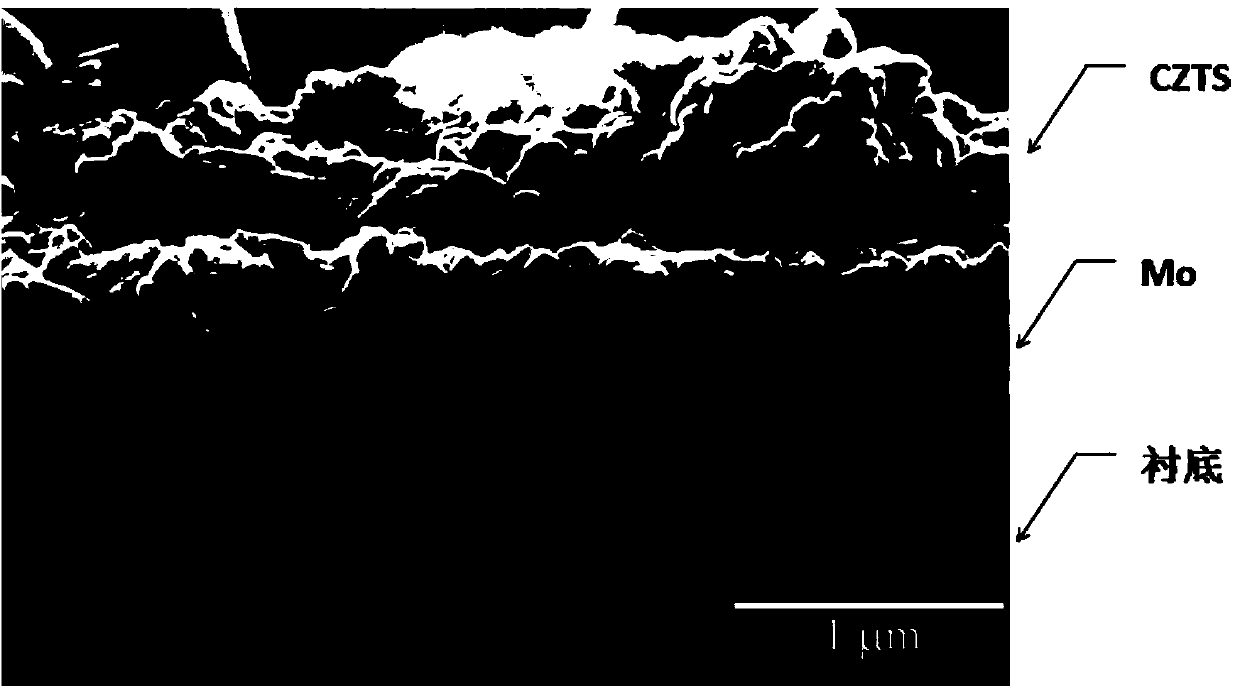

[0024] 1. The preparation of the Mo back contact layer is mainly divided into two steps. First, the vacuum degree of the back is higher than 10 -4 Pa, under the condition of argon working pressure of 1-3Pa, DC magnetron sputtering for 2-6 minutes under the condition of 130W power, a Mo film with strong adhesion to the glass substrate is obtained; Under the condition of DC magnetron sputtering for 20-40 minutes under the power condition of 130W, a Mo film with a small resistivity is obtained, and the Mo film with a double-layer structure forms the back electrode of the battery.

[0025] 2. Preparation of Cu on Mo film by electrochemical plating 2 S prefabricated layer, the specific steps are as follows: first prepare the electrolyte solution with the following formula: sodium citrate (0.5mol / L), CuSO 4 (0.286mol / L),Na 2 S 2 o 3 , adding an appropriate amount of HCl to adjust the pH value of the electroplating solution to 2.5; then deposit Cu on the prepared Mo film at a pot...

Embodiment 2

[0032] 1. The preparation of the Mo back contact layer is mainly divided into two steps. First, the vacuum degree of the back is higher than 10 -4 Pa, under the condition of argon working pressure of 1-3Pa, DC magnetron sputtering for 2-6 minutes under the condition of 130W power, a Mo film with strong adhesion to the glass substrate is obtained; Under the condition of DC magnetron sputtering for 20-40 minutes under the power condition of 130W, a Mo film with a small resistivity is obtained, and the Mo film with a double-layer structure forms the back electrode of the battery.

[0033] 2. Preparation of Cu on Mo film by DC magnetron sputtering 2 Se prefabricated layer, using DC magnetron sputtering system, using copper single target as raw material, and the vacuum degree of the back is higher than 10 -4 Pa, the working pressure is 0.3-1Pa, and the sputtering power is 30-100W, DC magnetron sputtering for 20-30 minutes, physical vapor deposition of copper metal precursor on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com