Planetary reducer

A planetary reducer and planet carrier technology, which is applied in the directions of transmission parts, gear transmissions, belts/chains/gears, etc., can solve the problems of high technological difficulty and high manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

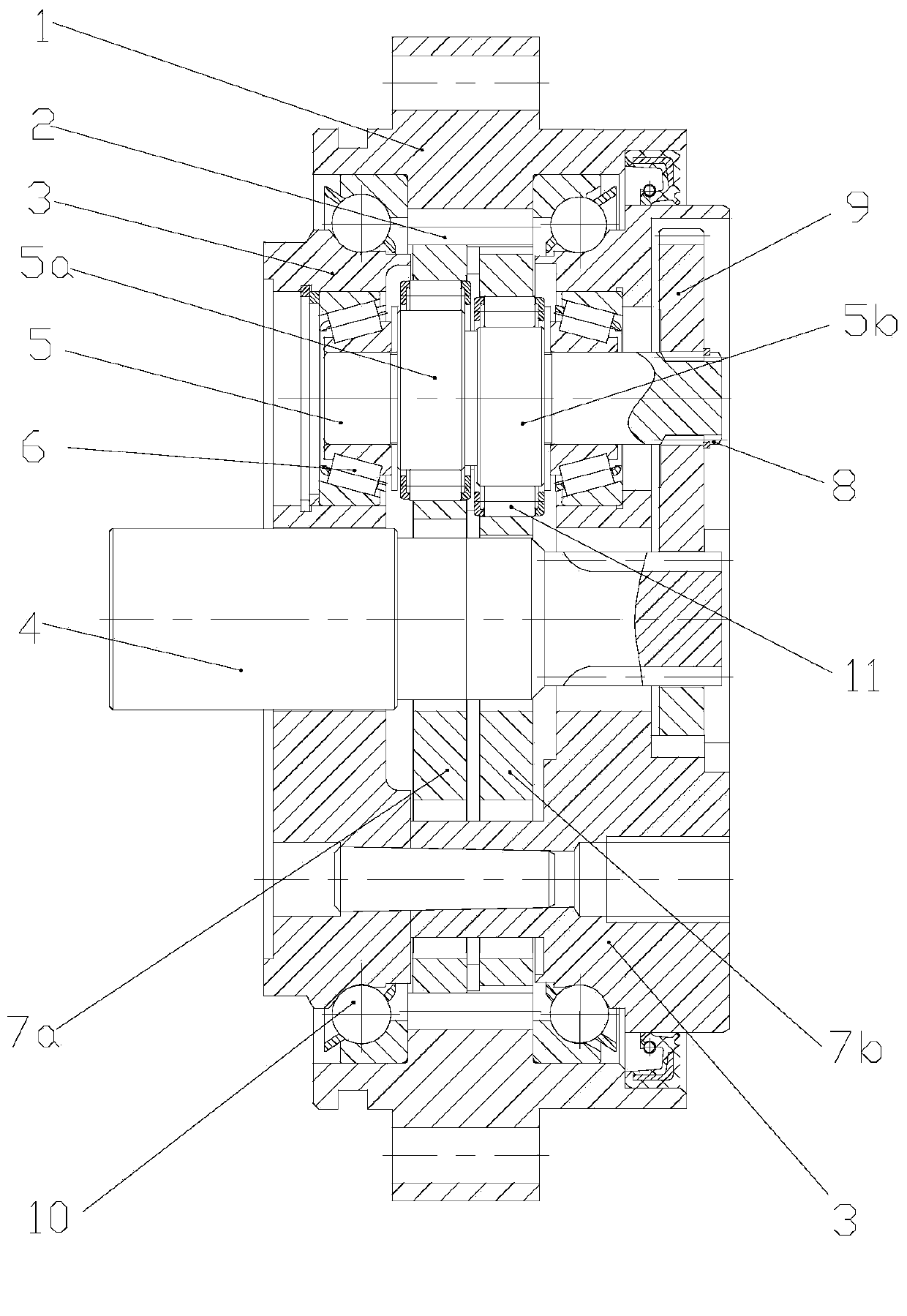

[0032] A planetary reducer, which can be used to connect to the joint of an industrial robot, is composed of a first-stage planetary gear mechanism and a first-stage small-tooth-difference gear transmission mechanism. The planetary gear mechanism consists of a sun gear and planetary gears. The small-tooth-difference gear transmission mechanism is composed of an eccentric shaft, an external gear and an internal gear housing (including internal teeth), and the internal gear housing is fixed. The eccentric shaft is fixedly connected with the planetary gear as the input shaft of the gear transmission mechanism with small tooth difference. The power is input from the central gear of the planetary gear mechanism, and is transmitted to the external gear through the eccentric shaft solidly connected with the planetary gear. The external gear is connected between the eccentric shaft and the internal gear. Under the joint action of the shell (internal teeth), the plane motion makes the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com