Loess hilly-and-gully area coal-mining subsidence and crevice treatment method

A technology for subsidence cracks and gully areas, applied in the direction of filling, etc., can solve the problems of crack reappearance and poor crack treatment effect, and achieve the effect of fast treatment speed, good treatment effect and accelerated ecological reconstruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

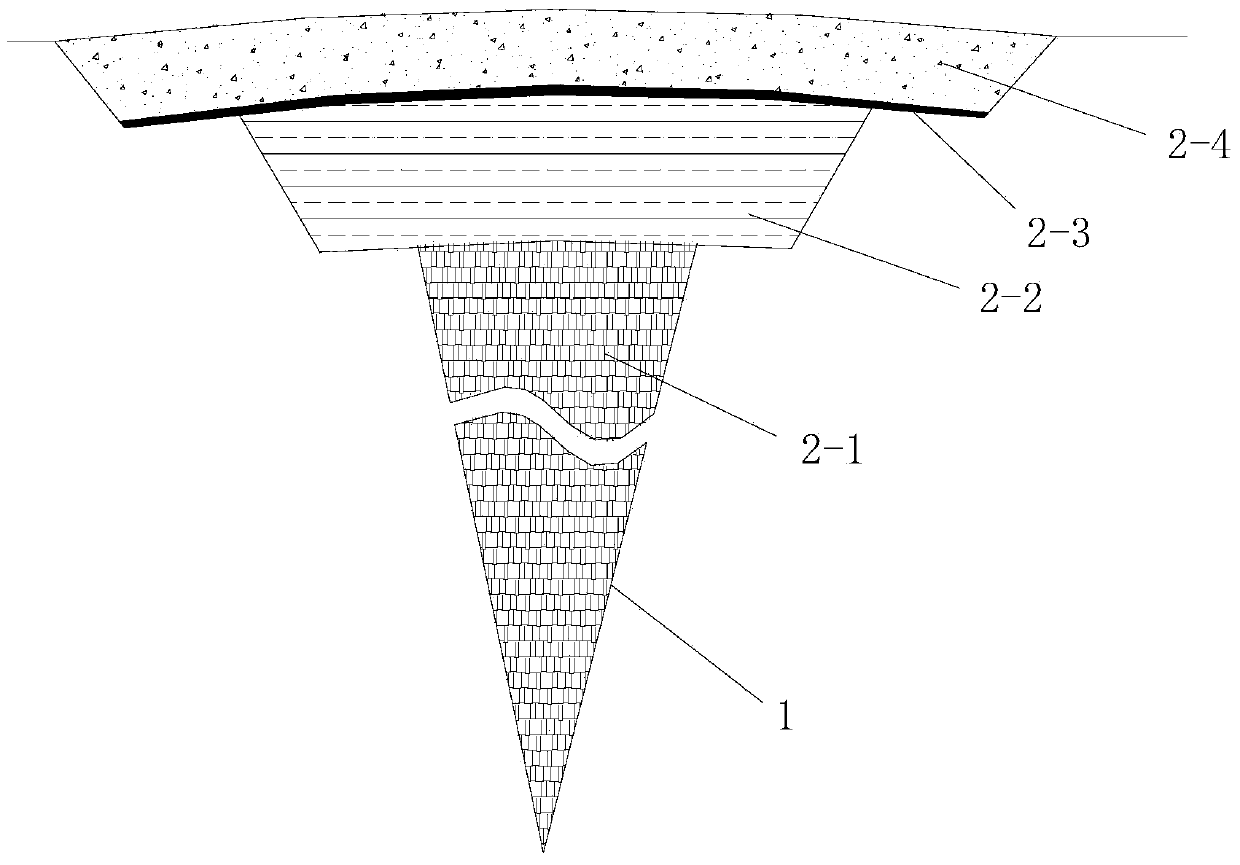

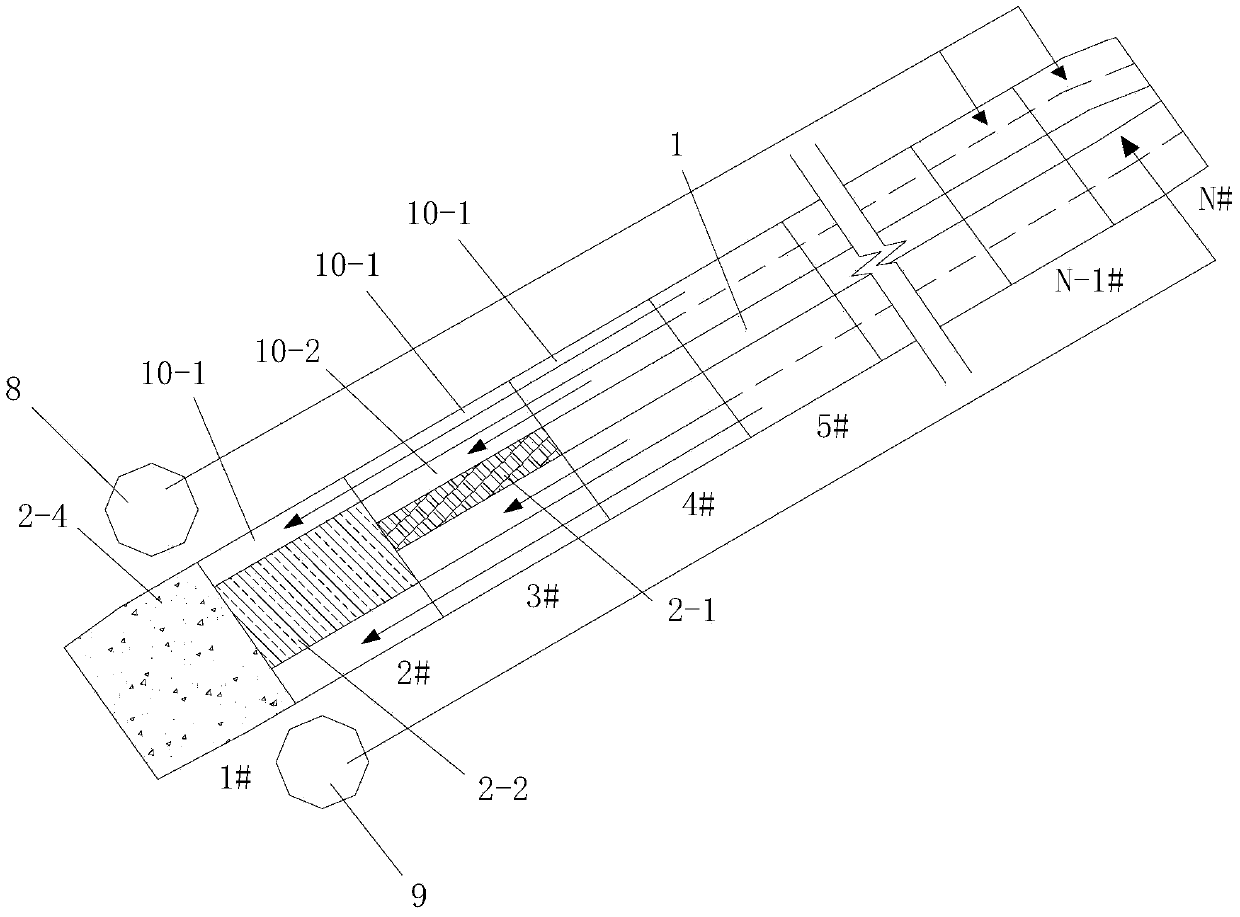

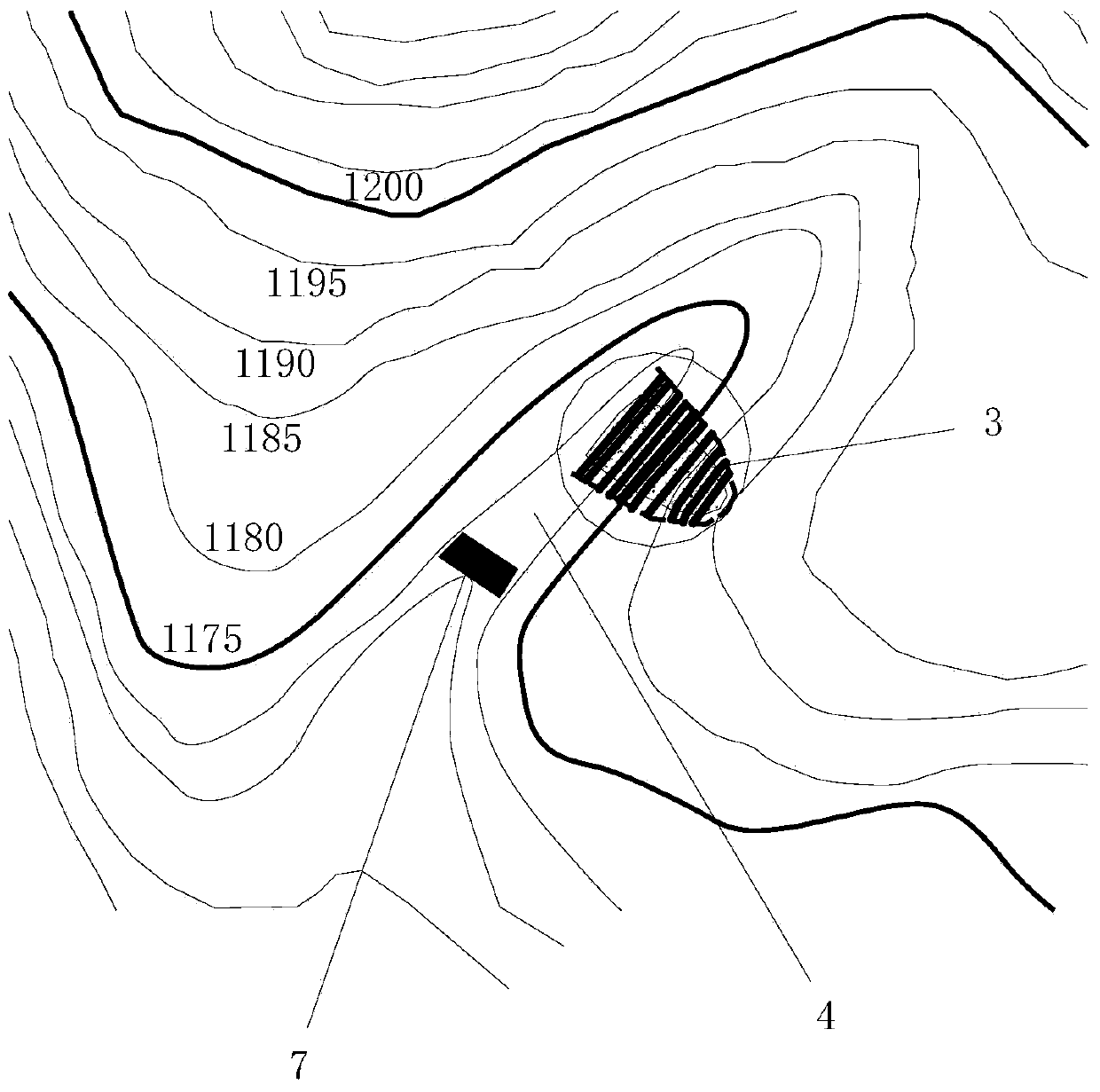

[0062] The method for treating coal mining subsidence cracks in loess hilly and gully areas according to the present invention adopts the filling method of section stripping and staggered backfilling to control the collapse cracks 1 existing in the treated loess hilly and gully areas, and the filling in the collapse cracks 1 The structure from bottom to top is cushion layer 2-1, raw soil layer 2-2 and surface soil layer 2-4, see figure 1 ; The governance process of the collapse crack 1 is as follows:

[0063] Step 1. Division of treatment sections: divide the crack 1 to be treated from front to back along the longitudinal extension direction into multiple treatment sections, the number of the multiple treatment sections is N and the lengths are the same, where N is A positive integer and N>3; the N governance sections are respectively the first section, the second section, ..., the Nth section according to the layout position from front to back.

[0064] In this embodiment, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com