Water-based color-showing resin emulsion, preparation method and applied coating composition

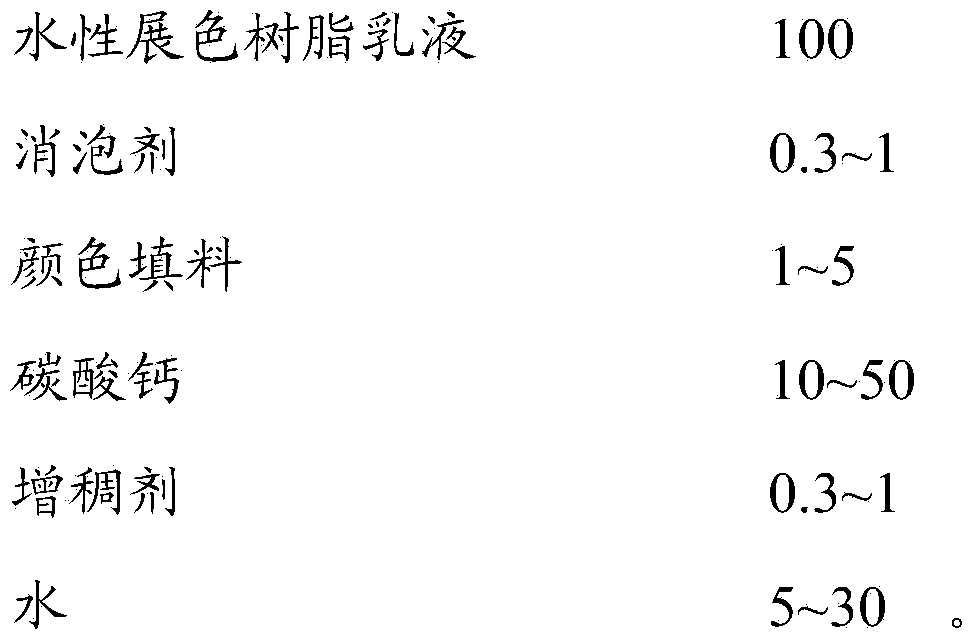

A coating composition, resin emulsion technology, applied in the direction of coating, can solve the problems of adverse effects of construction and use environment, price increase, non-competitiveness, etc., to improve film-forming defects, reduce dosage, compatibility Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

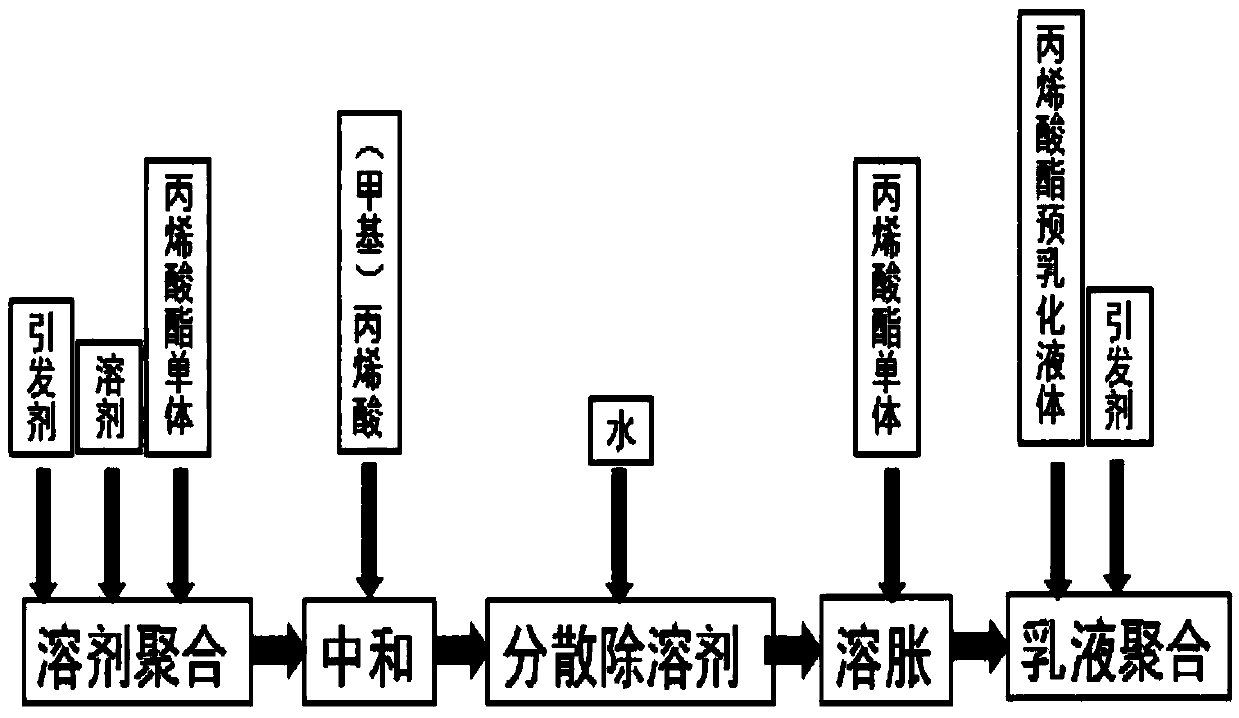

Method used

Image

Examples

Embodiment 1

[0050] (1) Add 290g ethyl acetate, 40g methyl methacrylate, 15g n-butyl acrylate, 15g n-butyl methacrylate, 26g isooctyl acrylate and 4g of dimethylaminoethyl methacrylate, mixed well, heated up to 55°C, added 10g of 0.5wt% azobisisobutyronitrile-ethyl acetate solution, and reacted for 3h;

[0051] (2) Lower the system 1 to room temperature, add 2.5g of methacrylic acid, and stir for 0.5h;

[0052] (3) Use a vacuum pump to extract the solvent at 65°C. When the extracted solvent is between 100 and 170g, remove the vacuum device and stir at a high speed (high-speed stirring is based on the ability to completely and evenly disperse the prepolymer in water) Add 300g of water to obtain a water dispersion, and continue to use a vacuum pump to extract the remaining solvent;

[0053] (4) Use 15g of n-butyl acrylate and 15g of n-butyl methacrylate to swell the water dispersion in system 3;

[0054] (5) Use system 4 as the seed emulsion, add 10g of 1wt% ammonium persulfate aqueous sol...

Embodiment 2

[0059] (1) Add 290g ethyl acetate, 60g methyl methacrylate, 10g n-butyl acrylate, 10g n-butyl methacrylate, 16g isooctyl acrylate and 4g of dimethylaminoethyl methacrylate, mixed well, heated up to 55°C, added 0.5wt% azobisisobutyronitrile-ethyl acetate, 10g, and reacted for 3h;

[0060] (2) Cool system 1 to room temperature, add 1.85g of acrylic acid, and stir for 0.5h;

[0061] (3) Use a vacuum pump to extract the solvent at 65°C. When the extracted solvent is between 100 and 170g, remove the vacuum device and stir at a high speed (high-speed stirring is based on the ability to completely and evenly disperse the prepolymer in water) Add 300g of water to obtain a water dispersion, and continue to use a vacuum pump to extract the remaining solvent;

[0062] (4) Use 5g of n-butyl acrylate and 25g of n-butyl methacrylate to swell the water dispersion in system 3;

[0063] (5) Use system 4 as the seed emulsion, add 10g of 1wt% ammonium persulfate aqueous solution, raise the tem...

Embodiment 3

[0068] (1) Add 290g ethyl acetate, 10g methyl methacrylate, 40g n-butyl acrylate, 40g n-butyl methacrylate, 6g isooctyl acrylate and 4g of dimethylaminoethyl methacrylate, mixed well, heated up to 55°C, added 0.5wt% azobisisobutyronitrile-ethyl acetate, 10g, and reacted for 3h;

[0069] (2) Cool system 1 to room temperature, add 1.85g of acrylic acid, and stir for 0.5h;

[0070] (3) Use a vacuum pump to extract the solvent at 65°C. When the extracted solvent is between 100 and 170g, remove the vacuum device and stir at a high speed (high-speed stirring is based on the ability to completely and evenly disperse the prepolymer in water) Add 300g of water to obtain a water dispersion, and continue to use a vacuum pump to extract the remaining solvent;

[0071] (4) Use 30g of the aqueous dispersion in n-butyl acrylate swelling system 3;

[0072] (5) Use system 4 as the seed emulsion, add 10g of 1wt% ammonium persulfate aqueous solution, raise the temperature to 80°C, and react fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com