Pre-gelatinized starch and preparation method thereof

A pregelatinized starch and pregelatinization technology, which is applied in the field of pregelatinized starch and its preparation, can solve the problems of pregelatinized starch production decline, low product solubility, high product viscosity, etc., and achieve low feed water content, Convenient on-site use and moderate product viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

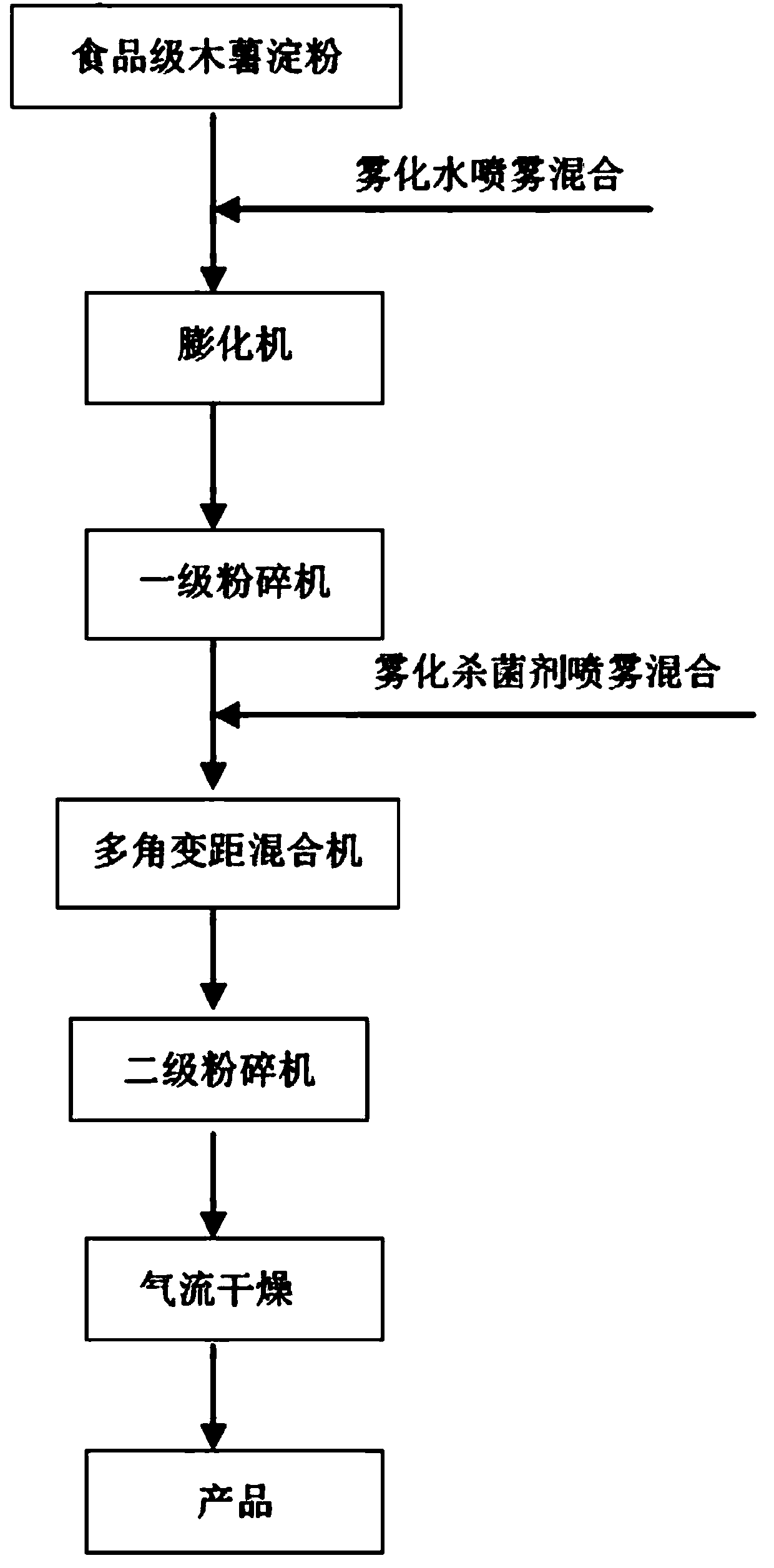

Method used

Image

Examples

Embodiment 1

[0048] A kind of pregelatinized starch, by weight percentage, comprising:

[0049] Pregelatinized tapioca starch 88.00

[0050] 2-Methyl-4-isothiazolin-3-one (MI) 0.5%

[0051] 5-Chloro-2-methyl-4-isothiazolin-3-one (CMI) 0.5%

[0052] The balance is water.

[0053] Wherein, the above-mentioned pregelatinized starch has the following properties:

[0054] performance

indicators

Exterior

White powder, no smell, no mechanical impurities

Pasting properties

Swells into a translucent paste in cold water

Moisture, %

≤12

Fineness, % (passing rate of 40 mesh sieve)

≥98

pH value (1% aqueous solution)

5.5-8.5

Apparent viscosity of 4%NaCl mud, mPa·s

≤9

4%NaCl mud API water loss, mL

≤10

Apparent viscosity of saturated NaCl mud, mPa·s

≤10

API water loss in saturated NaCl mud, mL

≤10

Anti-fermentation performance, h

≥72

[0055] A method for preparing above-ment...

Embodiment 2

[0061] A kind of pregelatinized starch, by weight percentage, comprising:

[0062] Pregelatinized tapioca starch 93.00

[0063] 2-Methyl-4-isothiazolin-3-one (MI) 0.1%

[0064] 5-Chloro-2-methyl-4-isothiazolin-3-one (CMI) 0.1%

[0065] The balance is water.

[0066] A method for preparing above-mentioned pregelatinized starch, comprising the following steps:

[0067] (1) Spray water into the starch, introduce it into an extruder to heat and pressurize it, press it out through the pores, expand it, evaporate the water, and dry it;

[0068] (2) After natural cooling, pulverize, add fungicide, mix and pulverize to obtain the product of the present invention.

[0069] Wherein, in the step (1), heat to 120-140°C and pressurize to 30-50×10 5 Pa; the pore diameter in the step (1) is 0.6mm.

[0070] In the step (1), spray prefabricated wet powder technology is used to spray water into the starch; in the step (1), the wet powder is extruded into the extruder by extrusion technolo...

Embodiment 3

[0072] A kind of pregelatinized starch, by weight percentage, comprising:

[0073] Pregelatinized tapioca starch 99.00

[0074] 2-Methyl-4-isothiazolin-3-one (MI) 0.1%

[0075] 5-Chloro-2-methyl-4-isothiazolin-3-one (CMI) 0.1%

[0076] The balance is water.

[0077] Wherein, the above-mentioned pregelatinized starch has the following properties:

[0078] performance

indicators

Exterior

White powder, no smell, no mechanical impurities

Pasting properties

Swells into a translucent paste in cold water

Moisture, %

≤12

Fineness, % (passing rate of 40 mesh sieve)

≥98

pH value (1% aqueous solution)

5.5-8.5

Apparent viscosity of 4%NaCl mud, mPa·s

≤9

4%NaCl mud API water loss, mL

≤10

Apparent viscosity of saturated NaCl mud, mPa·s

≤10

API water loss in saturated NaCl mud, mL

≤10

Anti-fermentation performance, h

≥72

[0079] A method for preparing above-me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com