Method of preparing propylene from ethylene and butylene

A technology of butene and ethylene, applied in chemical instruments and methods, metathesis reaction for hydrocarbon production, metal/metal oxide/metal hydroxide catalysts, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

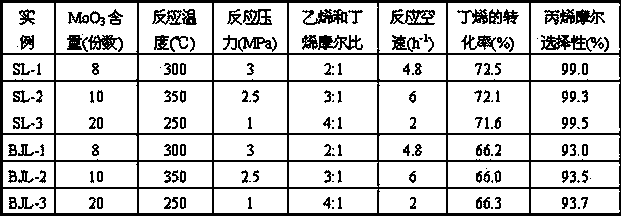

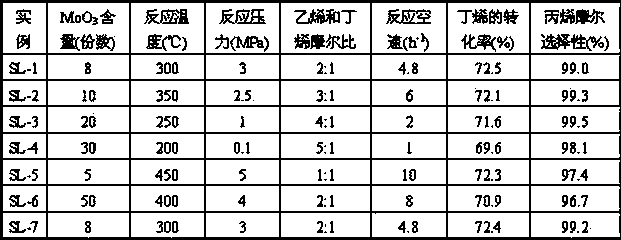

Examples

Embodiment 1

[0022] Weigh 500 grams of commercial MgO, add 2.5 liters of deionized water, heat and stir the resulting white turbid solution at 80°C for 5 hours, filter the water in the solution with suction, and dry the product at 120°C for 6 hours to obtain a magnesium oxide carrier.

[0023] Mix 200 grams of carrier magnesia and 1% scallop powder and put them into the blender evenly. After stirring for 12 minutes, add 19 grams of ammonium dimolybdate, then add 250 grams of deionized water, knead, extrude, and dry at 550 The catalyst was prepared by calcining at ℃ for 4 hours, which was designated as SL-1.

[0024] The evaluation of the catalyst was carried out on an olefin disproportionation evaluation device, and the raw materials were 60% butene-1 and 40% 2-butene in terms of mass fraction. The reaction is at a temperature of 300°C, a pressure of 3 MPa in absolute pressure, a molar ratio of ethylene to butene of 2:1 and a weight space velocity of butene of 4.8 hours -1 The evaluation ...

Embodiment 2

[0027] Weigh 500 grams of commercial MgO, add 2 liters of deionized water, and heat and stir the obtained white turbid solution at 60°C for 4 hours, then let it stand for 2 hours, filter the water in the solution, and dry the product at 120°C for 4 hours to obtain the magnesium oxide carrier .

[0028] Mix 200 grams of carrier magnesia and 1% scallop powder and put them into the blender evenly. After stirring for 30 minutes, add 24 grams of ammonium dimolybdate, then add 150 grams of deionized water, knead, extrude, and dry at 550 The catalyst was prepared by calcining at ℃ for 4 hours, which was designated as SL-2.

[0029] The evaluation of the catalyst was carried out on an olefin disproportionation evaluation device. The reaction was carried out at a temperature of 350°C, a pressure of 2.5 MPa in absolute pressure, a molar ratio of ethylene to butene of 3:1 and a weight space velocity of butene of 6 hours. -1 The evaluation was carried out under the conditions, and the ev...

Embodiment 3

[0032] Weigh 500 grams of commercial MgO, add 1.5 liters of deionized water, and heat and stir the obtained white turbid solution at 100°C for 2 hours, then let it stand for 2 hours, filter the water in the solution, and dry the product at 100°C for 8 hours to obtain a magnesium oxide carrier .

[0033] Mix 200 grams of carrier magnesia and 1% scallop powder and put them into the blender evenly. After stirring for 20 minutes, add 48 grams of ammonium dimolybdate, then add 180 grams of deionized water, knead, extrude, and dry at 550 The catalyst was prepared by calcining at ℃ for 4 hours, which was designated as SL-3.

[0034] The evaluation of the catalyst was carried out on an olefin disproportionation evaluation device. The reaction was carried out at a temperature of 250°C, a pressure of 1 MPa in absolute pressure, a molar ratio of ethylene to butene of 4:1 and a weight space velocity of butene of 2 hours. -1 The evaluation was carried out under the conditions, and the eva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com