A kind of calcium titanate/calcium oxide composite photocatalyst and its preparation method and application

A technology of calcium oxide and calcium titanate, applied in the field of photocatalysis, can solve the problem of low photocatalytic activity, achieve high photocatalytic activity, cheap and easy-to-obtain raw materials, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

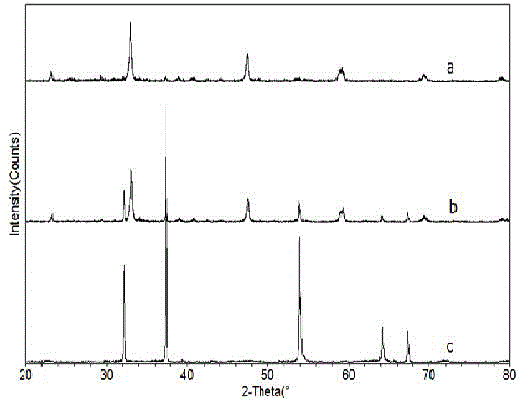

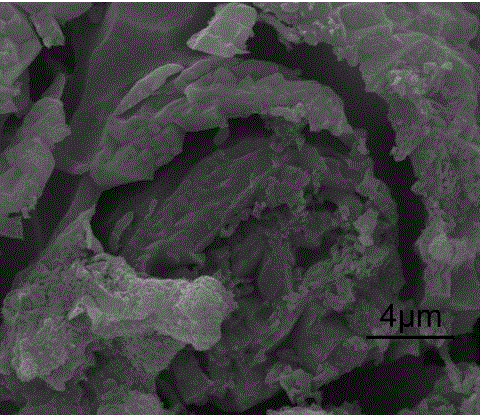

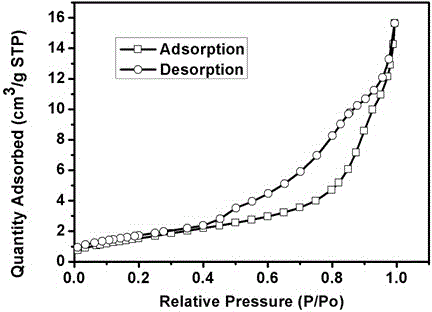

Embodiment 1

[0041] (1) Dissolve 0.0491mol of butyl titanate in 80ml of absolute ethanol, ultrasonicate for 1h, and let stand for 12h;

[0042] (2) Add 0.0491mol of solid calcium nitrate tetrahydrate into 80ml of 95% ethanol solution, heat and stir at 60°C to fully dissolve, then add 15ml of glacial acetic acid, and stir well for 0.5h;

[0043] (3) Under full stirring, the solution obtained in step (2) is added dropwise to the solution obtained in step (1), and stirring is continued for 1 h, wherein the molar ratio of calcium to titanium is 1:1;

[0044] (4) aging the solution obtained in step (3) at room temperature for 24h;

[0045] (5) Put the obtained pale yellow transparent gel into an oven to dry at 60°C to obtain a pale yellow solid;

[0046] (6) Put the dried light yellow solid into a muffle furnace for calcination at 500°C for 2h, and the heating rate is 1°C / min, and the obtained white powder is the calcium titanate / calcium oxide composite photocatalyst.

[0047] 10 mg of ca...

Embodiment 2

[0049] (1) Dissolve 0.0491mol of tetraisopropyl titanate in 80ml of absolute ethanol, sonicate for 1h and then let stand for 12h;

[0050] (2) Add 0.0491mol of solid calcium nitrate tetrahydrate into 80ml of 95% ethanol solution, heat and stir at 60°C to fully dissolve, then add 15ml of glacial acetic acid, and stir well for 0.5h;

[0051] (3) Under full stirring, the solution obtained in step (2) is added dropwise to the solution obtained in step (1), and stirring is continued for 1 h, wherein the molar ratio of calcium to titanium is 1:1;

[0052] (4) aging the solution obtained in step (3) at room temperature for 24h;

[0053] (5) Put the obtained pale yellow transparent gel into an oven to dry at 60°C to obtain a pale yellow solid;

[0054] (6) Put the dried light yellow solid into a muffle furnace for calcination at 700°C for 2h, and the heating rate is 1°C / min, and the obtained white powder is the calcium titanate / calcium oxide composite photocatalyst.

[0055] 2 mg of...

Embodiment 3

[0057] (1) Dissolve 0.0491mol of butyl titanate in 80ml of absolute ethanol, ultrasonicate for 1h, and let stand for 12h;

[0058] (2) Add 0.0491mol of calcium chloride dihydrate solid into 80ml of 95% ethanol solution, heat and stir at 60°C to fully dissolve, then add 15ml of glacial acetic acid, and stir well for 0.5h;

[0059] (3) Under full stirring, the solution obtained in step (2) is added dropwise to the solution obtained in step (1), and stirring is continued for 1 h, wherein the molar ratio of calcium to titanium is 1:1;

[0060] (4) aging the solution obtained in step (3) at room temperature for 24h;

[0061] (5) Put the obtained pale yellow transparent gel into an oven to dry at 60°C to obtain a pale yellow solid;

[0062] (6) Put the dried light yellow solid into a muffle furnace for calcination at 600°C for 4h, and the heating rate is 1°C / min, and the obtained white powder is the calcium titanate / calcium oxide composite photocatalyst.

[0063] 2 mg ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com