A kind of preparation method of graphene oxide composite nanofiltration membrane

A graphene composite and nanofiltration membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of limited application, nanofiltration membrane preparation and performance, less involvement, and difficult dispersion, etc., to achieve high Hydrophilicity, increase flux and desalination effect, increase the effect of salt interception rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

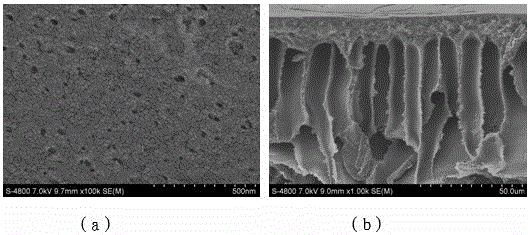

Image

Examples

Embodiment 1

[0031] (1). The graphene oxide aqueous solution was prepared by the modified Hummmers method.

[0032] Put expandable graphite as raw material in a container, add concentrated sulfuric acid with a mass fraction of 98% to the expandable graphite, keep the temperature of the mixture at 0°C in an ice-water bath, then add potassium permanganate, when the temperature is lower than 20 Stir evenly under the condition of ℃, add 50ml of concentrated sulfuric acid for every 1g of expandable graphite, and the quality of potassium permanganate is twice that of expandable graphite.

[0033] Add ultrapure water to the above solution for dilution, heat it in a constant temperature water bath to 90-100°C, keep it for 30-40min, then add hydrogen peroxide solution with a mass fraction of 30%, and cool it to room temperature, the solution changes from brown to soil Yellow, the volume ratio of concentrated sulfuric acid: ultrapure water: hydrogen peroxide is 50:100:10.

[0034] Filter the above ...

Embodiment 2

[0040] (1). The graphene oxide aqueous solution was prepared by the modified Hummmers method.

[0041] Put expandable graphite as raw material in a container, add concentrated sulfuric acid with a mass fraction of 98% to the expandable graphite, keep the temperature of the mixture at 0°C in an ice-water bath, then add potassium permanganate, when the temperature is lower than 20 Stir evenly under the condition of ℃, add 60ml of concentrated sulfuric acid for every 1g of expandable graphite, and the quality of potassium permanganate is 3 times that of expandable graphite.

[0042] Add ultrapure water to the above solution for dilution, heat it in a constant temperature water bath to 90-100°C, keep it for 30-40min, then add hydrogen peroxide solution with a mass fraction of 30%, and cool it to room temperature, the solution changes from brown to soil Yellow pasty colloid, the volume ratio of concentrated sulfuric acid: ultrapure water: hydrogen peroxide is 50:200:20.

[0043] Fil...

Embodiment 3

[0049] (1). The graphene oxide aqueous solution was prepared by the modified Hummmers method.

[0050] Put expandable graphite as raw material in a container, add concentrated sulfuric acid with a mass fraction of 98% to the expandable graphite, keep the temperature of the mixture at 0°C in an ice-water bath, then add potassium permanganate, when the temperature is lower than 20 Stir evenly under the condition of ℃, add 75ml of concentrated sulfuric acid for every 1g of expandable graphite, and the quality of potassium permanganate is 4 times that of expandable graphite.

[0051] Add ultrapure water to the above solution for dilution, heat it in a constant temperature water bath to 90-100°C, keep it for 30-40min, then add hydrogen peroxide solution with a mass fraction of 30%, and cool it to room temperature, the solution changes from brown to soil Yellow pasty colloid, the volume ratio of concentrated sulfuric acid: ultrapure water: hydrogen peroxide is 50: 300: 40.

[0052]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com