Normal-temperature flue gas denitration method

A flue gas and denitrification technology, applied in the field of normal temperature flue gas denitrification process, can solve the problems of low ammonia removal nitrogen oxide treatment efficiency, high operating cost and high investment, and achieves the elimination of hidden dangers of explosion, low operating cost and high denitration efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] A normal temperature flue gas denitrification process is characterized in that it comprises the following steps:

[0029] 1) Dust removal;

[0030] 2) Desulfurization;

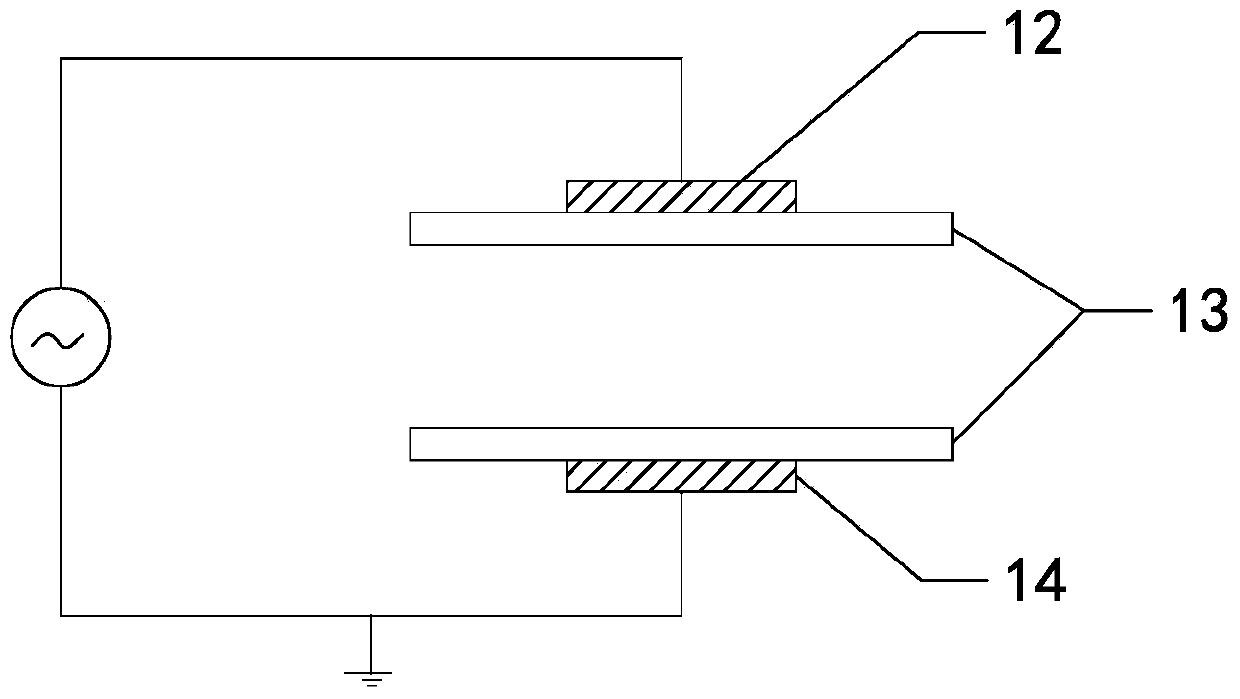

[0031] 3) Plasma oxidation;

[0032] 4) Spray the oxidized flue gas with alkaline aqueous solution to capture the oxidized substances in the flue gas.

[0033] Among them, the dust removal process adopts bag type dust removal, and the desulfurization process adopts desulfurization tower.

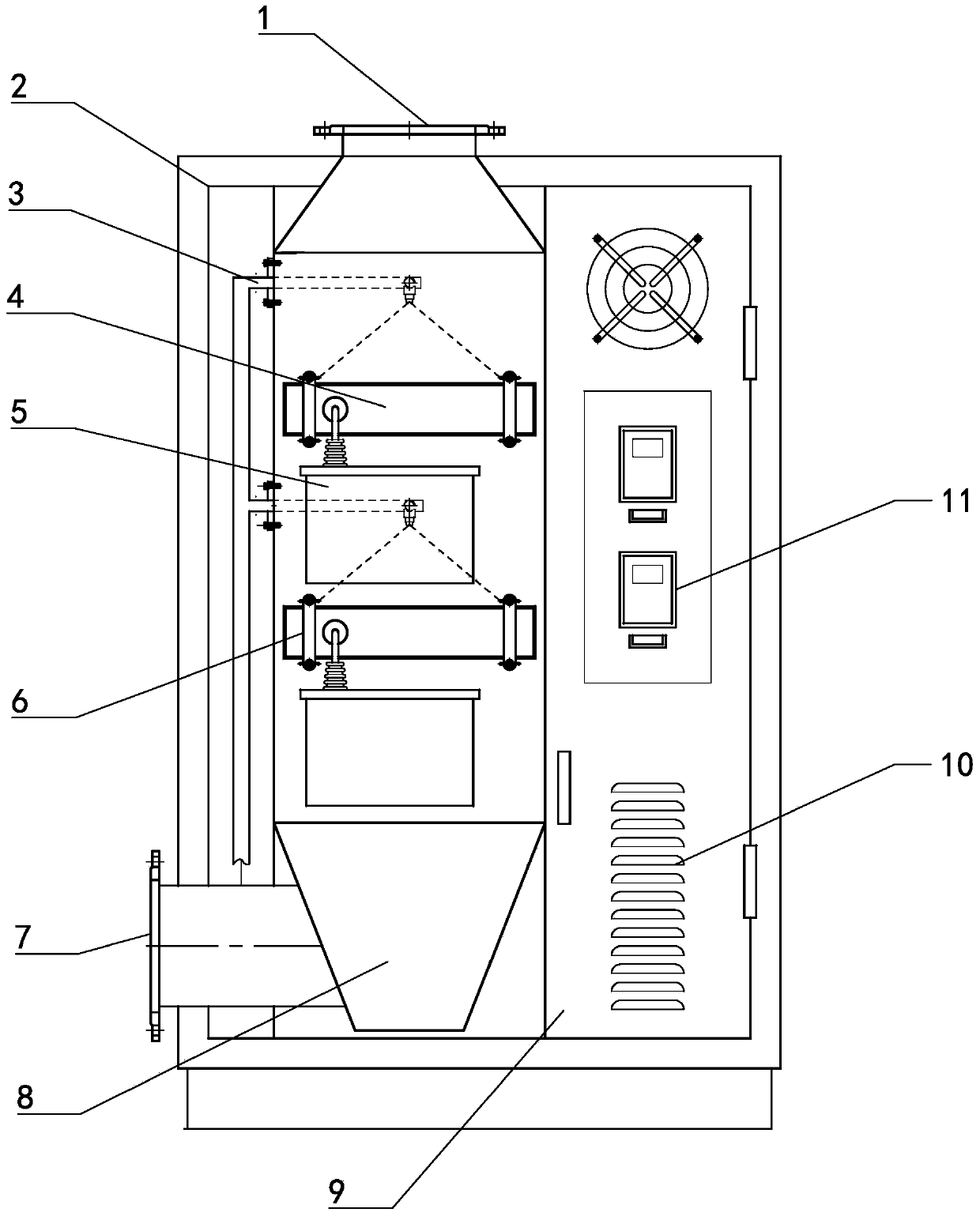

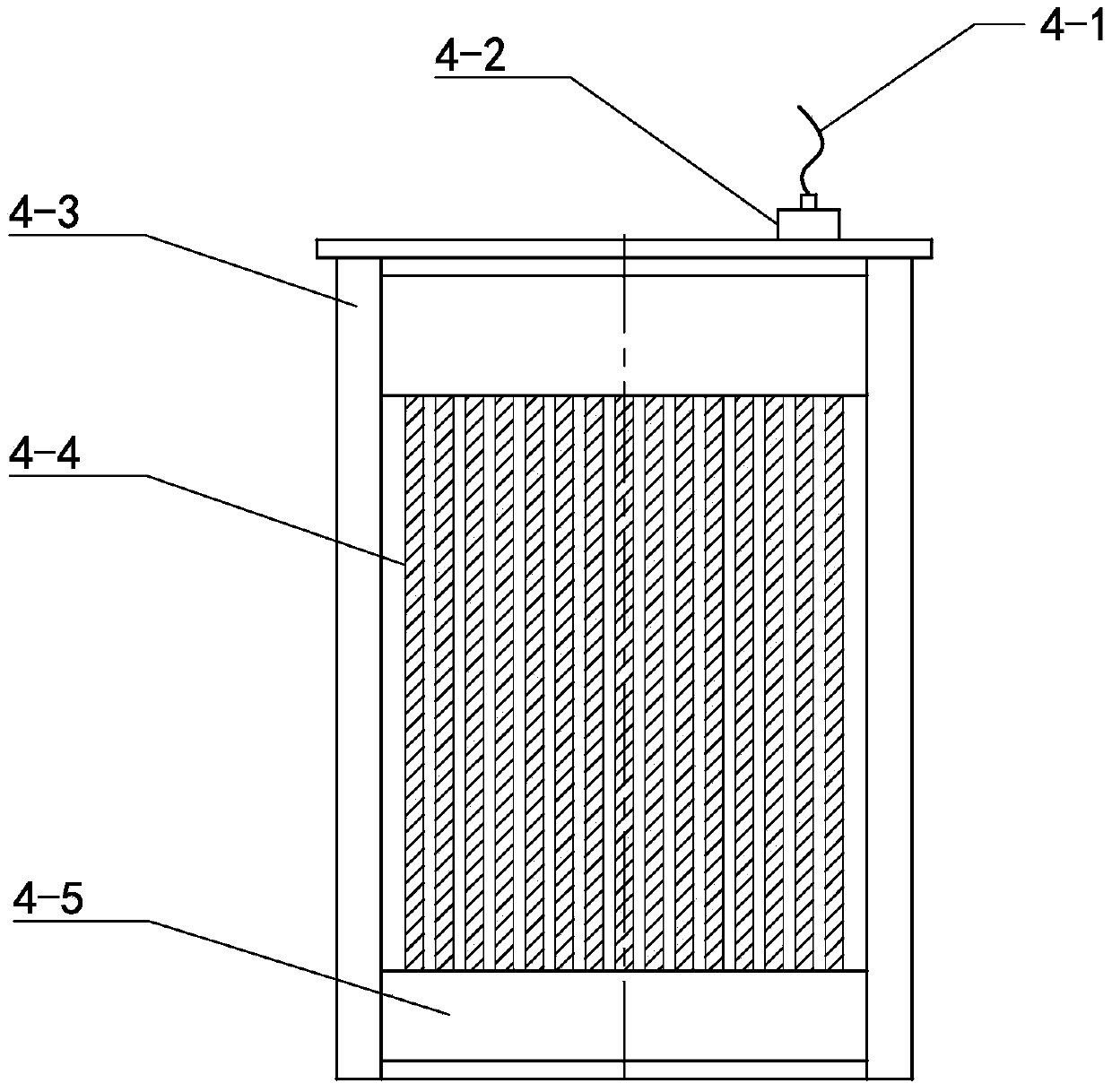

[0034] The row-type double dielectric barrier discharge plasma oxidizer includes a casing 9, a frame 2 is arranged in the casing 9, a single air duct 8 is arranged on the frame 2, and the single air duct 8 is arranged sequentially from top to bottom. Tuyere 1, spray device 3, plasma disk 4, single fuel tank 5 and disk gland device 6, the lower end of single air cylinder 8 is connected to air outlet 7. A heat sink 10 and a power supply 11 are also provided in the casing 9 .

[0035] Wherein, the frame 2 is to supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com