Preparation method of timolol maleate sustained release microspheres

A technology of timolol maleate and microspheres, which is applied in the field of medicine, can solve the problems of decreased drug encapsulation rate, long time consumption, and low yield, and achieve the effect of reducing discomfort in the eye and reducing the number of medications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The preparation method of timolol maleate sustained-release microspheres comprises the following steps:

[0027] 5) Disperse timolol maleate, acrylic resin, Tween, plasticizer, and montmorillonite in an organic solvent, so that the concentration of acrylic resin is 30-100g / L, and the concentration of Tween is 20-60g / L. L, the concentration of the plasticizer is 5-20g / L to obtain the inner phase;

[0028] 6) Dissolve Span in vegetable oil so that the concentration of Span is 10-40g / L to obtain the external phase;

[0029] 7) Under stirring, drop the inner phase into the outer phase to form an oil-in-oil emulsion;

[0030] 8) After the emulsion is ultrasonically treated for 5-30 minutes, the inner phase is evaporated under electromagnetic stirring, washed and dried to obtain sustained-release microspheres.

[0031] The emulsifying agent is very important to the stability of the oil-in-oil emulsion, and the emulsifying agent of the present invention is preferably cheap a...

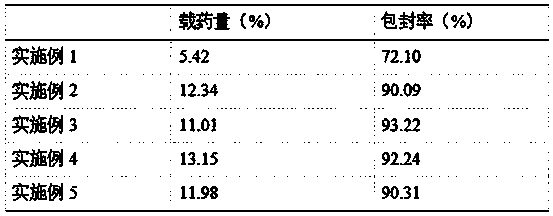

Embodiment 1

[0036] 1) Accurately weigh 30 mg of timolol maleate, 20 mg of sodium montmorillonite, 50 mg of TEC, 50 mg of glycerin, 400 mg of acrylic resin (RSPO: RLPO mass ratio = 2:1), 124 mg of Tween 80, and add 5 ml of acetonitrile , stir to disperse and mix to obtain the inner phase.

[0037] 2) Dissolve 248mg of Span 80 in 10ml of vegetable oil to obtain the external phase.

[0038] 3) At a stirring speed of 600rpm, add 0.3g of the inner phase into 5g of the outer phase dropwise, and disperse evenly to obtain an oil-in-oil emulsion.

[0039] 4) First place the emulsion in an ultrasonic cell disintegrator for 10 minutes of sonication, then evaporate the inner phase with electromagnetic stirring in an ice bath, wash with n-hexane, and dry at room temperature.

Embodiment 2

[0041] 1) Place 500 mg of sodium montmorillonite in 5v / v% sulfuric acid, activate it at 90°C for 2 hours, wash until neutral, and dry to obtain modified montmorillonite.

[0042] 2) Accurately weigh 30mg of timolol maleate, 20mg of modified montmorillonite, 50mg of TEC, 50mg of glycerin, 400mg of acrylic resin (RSPO: RLPO mass ratio = 2:1), 124mg of Tween 80, and add 5ml In acetonitrile, stir to disperse and mix to obtain the inner phase.

[0043] 3) Dissolve 248mg of Span 80 in 10ml of vegetable oil to obtain the external phase.

[0044] 4) At a stirring speed of 600rpm, add 0.3g of the inner phase to 5g of the outer phase dropwise, and disperse evenly to obtain an oil-in-oil emulsion.

[0045] 5) First place the emulsion in an ultrasonic cell disintegrator for 10 minutes of sonication, then evaporate the inner phase with electromagnetic stirring in an ice bath, wash with n-hexane, and dry at room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com