Multifunctional powder material processing equipment and processing method for pollen pini

A powder material and processing equipment technology, which is applied in the field of multifunctional powder material processing equipment and its use in the processing of pine pollen, can solve the problem of low screening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Embodiment 1: A multifunctional powder material processing equipment.

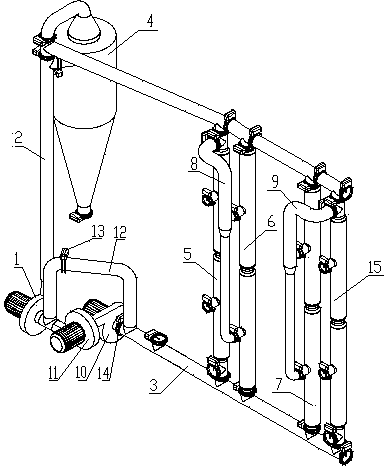

[0058] see Figures 1 to 13 , a multifunctional powder material processing equipment, including fan 1, positive pressure circulation pipeline 2, negative pressure circulation pipeline 3, cyclone dust collector branch 4, dust collector branch A5, sieve cylinder branch A6, sieve cylinder Branch B7, dust collector branch B15, screen cylinder discharge pipe A8, screen cylinder discharge pipe B9, ultraviolet sterilization lamp tube 46, fan A10, fan B11, bypass pipe 12, bypass valve 13, stop valve 14 .

[0059] Fan A10, fan B11, connected in series with fan 1, are used to increase the circulation speed of materials.

[0060] A stop valve 14 is installed on the air inlet of the fan A10, and a bypass pipe 12 is connected in parallel between the inlet of the stop valve 14 and the air outlet of the fan B11, and a bypass valve 13 is installed on the bypass pipe 12.

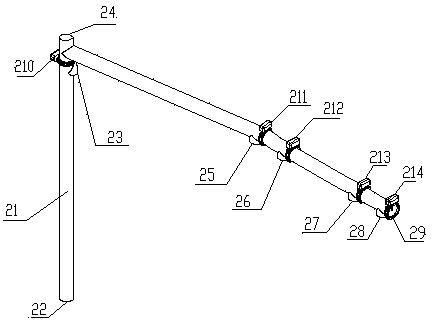

[0061] see figure 2 , positive pressure...

Embodiment 2

[0072] Embodiment 2: a kind of processing method of pine pollen, promptly apply the equipment in the first embodiment to carry out the drying of pine pollen, sterilization, impurity removal, pulverizing broken wall, the method for sieving, comprise the steps:

[0073] S1, drying

[0074] S101. Adjustment and start-up of the initial state of the equipment: after the equipment is powered on, all valves are closed, and fan 1, fan A10, and fan B11 are started. After the fans are started, the opening degree of the regulating valve 55 of the dust collector branch A5 is opened between 5% and 40%. , open the air intake valve 33 of the negative pressure circulation pipeline 3, the valve A210 of the positive pressure circulation pipeline 2, the inlet valve 51 of the dust collector branch A5, and adjust the regulating valve 55 of the dust collector branch A so that the dust collector branch The interior of A is in a positive pressure state, that is, part of the air flow is discharged fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com