Method of manufacturing silicon carbide-containing heat storage material from waste silicon sludge

A technology of heat storage material and manufacturing method, applied in the direction of manufacturing tools, applications, heat storage equipment, etc., can solve the problems of high production cost, heat storage layer does not have thermal conductivity, heat accumulation characteristics and chemical resistance, etc., to achieve low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0055] Example 1: Preparation of a sintered silicon carbide body

[0056] Silica sludge obtained from domestic semiconductor wafer fabs is centrifuged to recover silicon. The above Table 1 shows the composition of impurities contained in the solid of the obtained silica mud, that is, the silica mud contains impurities in addition to silicon (Si). Subsequently, the obtained silica mud was heat-treated at a temperature of 300° C. for 120 minutes in a reducing atmosphere to remove oil on the obtained silica mud. As a result, the remaining oil content in the silica mud was 5% by weight.

[0057] Subsequently, the silica mud was mixed with carbon black (manufactured by Korea Carbon Black Co., Ltd.) having a particle diameter of 1 μm to form a pellet parison. In this case, the molar ratio of carbon black to silicon is 1:1.

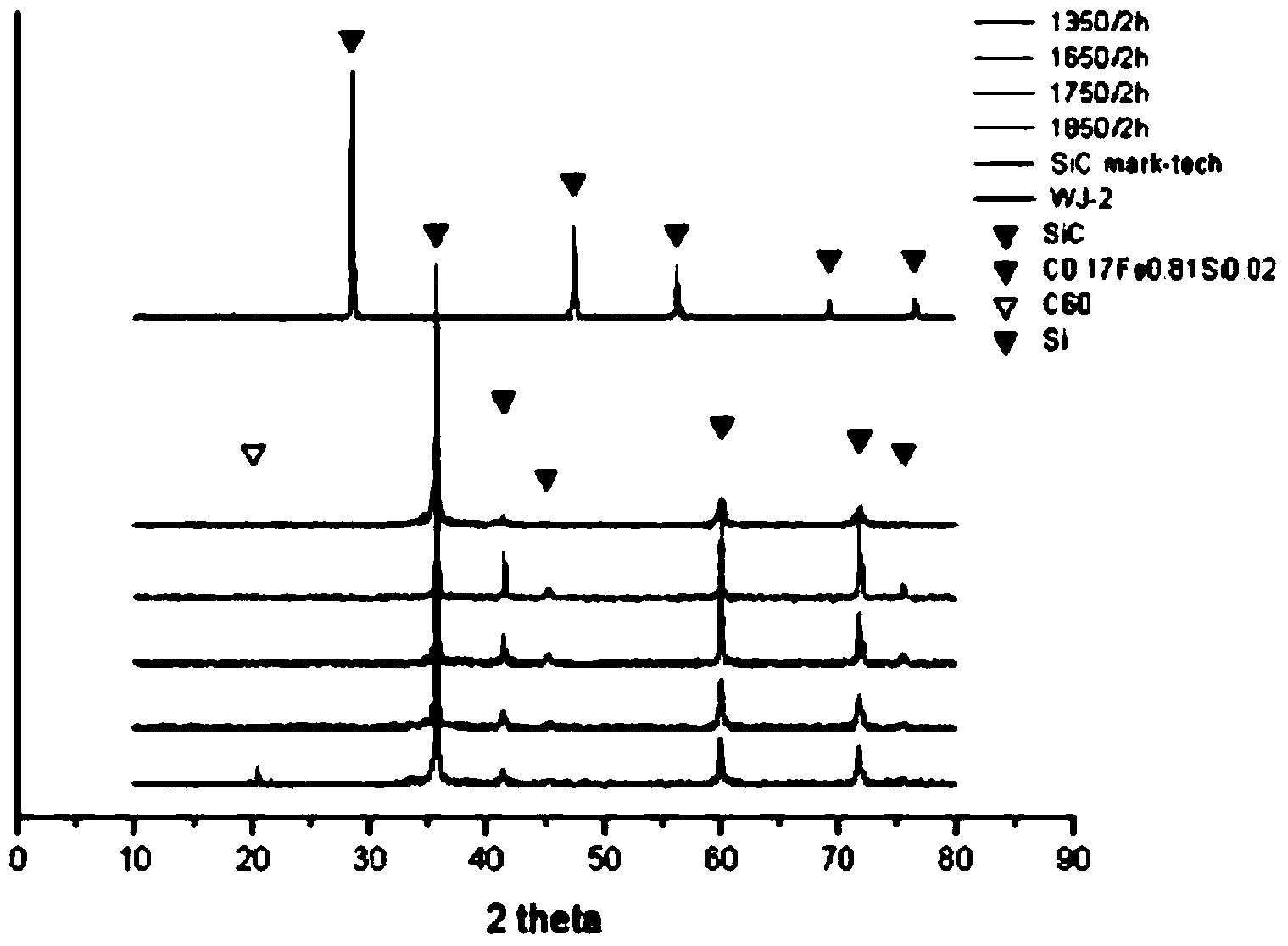

[0058] In a vacuum atmosphere, the billets were sintered at 1350°C, 1650°C, 1750°C and 1850°C for 1 hour. In this case, the sintering temperature was incr...

example 2

[0064] Example 2: Preparation of silicon carbide powder

[0065] The solid of silica mud obtained by the same method as in Example 1 was mixed with a carbon source, and then heat-treated at a temperature of 1450° C. to 1850° C. for 1 hour. In this case, the heat treatment temperature was increased at a rate of 10°C / min. Silicon carbide (SiC) powder was prepared in the same manner as in Example 1, except that the SiC powder was not formed into a pellet shape.

[0066] The appearance of the silicon carbide (SiC) powder prepared in this way was photographed with an electron microscope.

[0067] Figure 4 A to Figure 4 D shows the SEM images of silicon carbide powder samples heat-treated at 1450°C, 1650°C, 1750°C and 1850°C, Figure 5 is a graph showing the XRD analysis results of silicon carbide (SiC) powder prepared at 1450°C.

[0068] From Figure 5 It can be seen that β-SiC powder has been formed (KICET5:5 in the figure). "Marktech" and "SIKA" in the figure represent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com