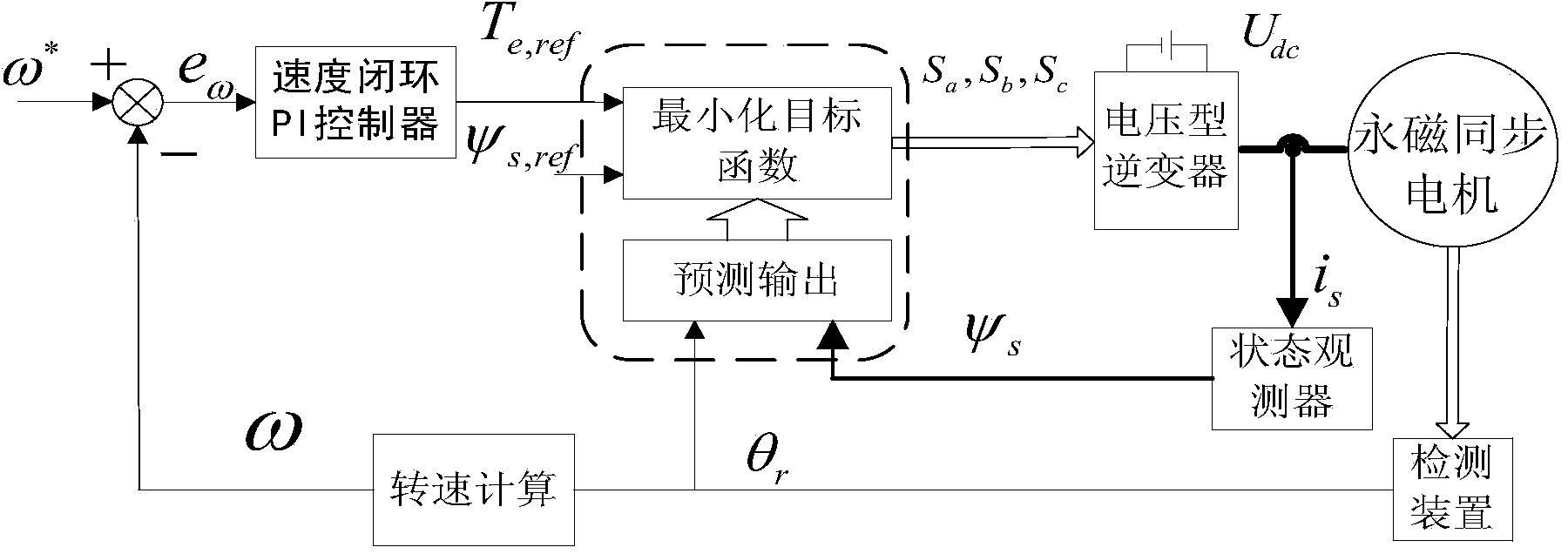

Permanent magnet synchronous motor low inverter power consumption direct torque control method and device

A permanent magnet synchronous motor and direct torque control technology, which is used in motor generator control, control of electromechanical transmission, electronic commutation motor control, etc., can solve problems such as complex algorithms and inability to apply in real time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

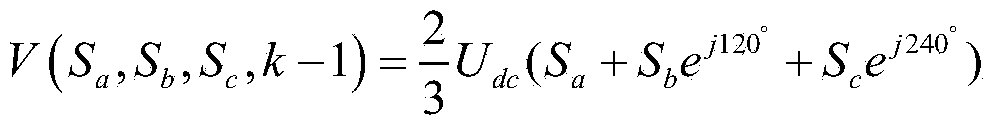

Examples

specific Embodiment approach

[0065] 1 Set K in the speed closed-loop control p =0.08, K i =0.8;

[0066] 2Set the reference speed ω * =900r / min;

[0067] 3 Set the reference flux linkage amplitude

[0068] 4 Sampling the motor phase current i in the inverter circuit through voltage and current sensors a i b i c and bus voltage U dc Calculate the observed value of the stator flux linkage at the current moment:

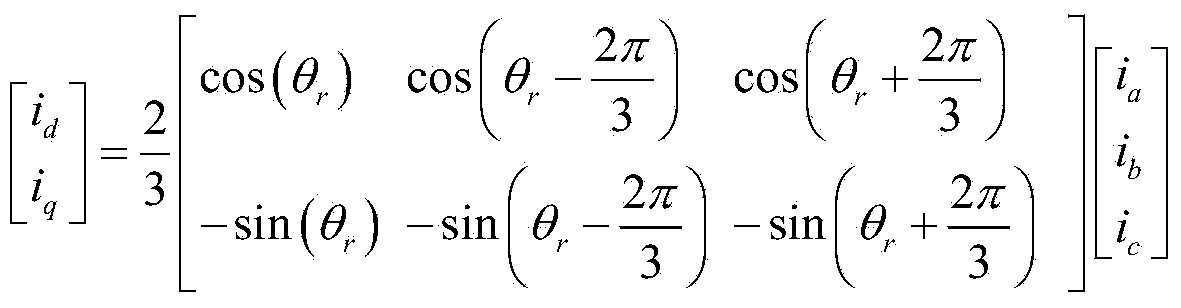

[0069] (4.1) First convert the current and voltage from the three-phase abc coordinate system to the two-phase d, q coordinate system

[0070] i d i q = 2 3 cos ( θ r ) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com