An automobile three-way catalytic converter assembly and its manufacturing and packaging process

A technology of three-way catalytic converter and packaging technology, which is applied in the direction of mufflers, exhaust devices, engine components, etc., can solve the problems of affecting the service life of the three-way catalytic converter, affecting the heat dissipation of the three-way catalytic converter, and shortening the service life. The effect of increasing the service life and conversion efficiency, saving material and man-hour costs, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

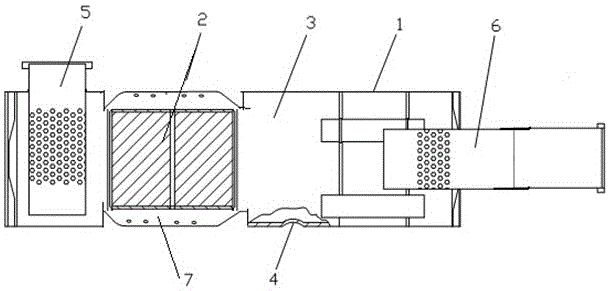

[0032] Embodiment 1 of the present invention provides an automobile three-way catalytic converter assembly, see figure 1 , the automobile three-way catalytic converter assembly includes an assembly barrel 1, a catalytic generator 2 arranged in the assembly barrel 1, a muffler chamber 3 arranged adjacent to the catalytic generator 2, and a muffler chamber arranged in the muffler chamber 3 The water outlet structure on the side wall of the assembly cylinder 1 4, the air inlet pipe 5 arranged at one end of the assembly cylinder 1, the air outlet pipe 6 arranged at the other end of the assembly cylinder 1, the outlet pipe 6 arranged at the place where the catalytic converter sounder 2 is located Assembling heat shields 7 on both sides of cylinder body 1.

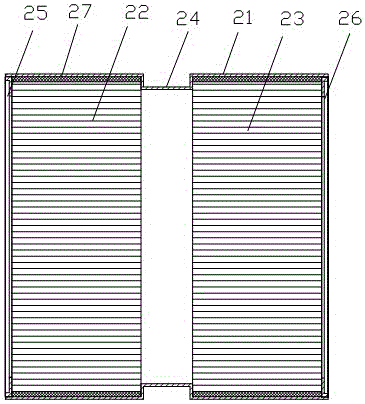

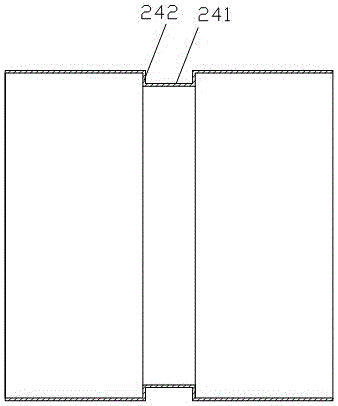

[0033] Specifically, see figure 2 , the catalyst generator 2 includes a catalyst generator cylinder 21, a first honeycomb carrier 22 and a second honeycomb carrier 23 symmetrically arranged in the catalyst generator cylinder 2...

Embodiment 2

[0040] Embodiment 2 of the present invention provides a manufacturing and packaging process for an automobile three-way catalytic converter assembly, see Figure 5 , the manufacture and packaging process of the automobile three-way catalytic converter assembly includes the following steps:

[0041] S101. Reel: Drill the straight board out of the inlet pipe installation hole and water outlet hole and roll it into an assembly cylinder;

[0042] S102. Rolling: roll another straight plate into a catalytic generator cylinder after pressing the groove;

[0043] S103. Loading: wrap the honeycomb carrier with a liner and load it into the cylinder of the catalytic converter generator;

[0044] S104. Shrinking: performing shrinking treatment on the cylinder of the catalyst generator with the liner and the honeycomb carrier installed;

[0045] S105. Welding: The catalytic generator cylinder is necked and welded to form;

[0046] S106. Compression: put the catalyst generator cylinder int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com