Method of low-temperature gas-assisted coalbed methane fracturing technology

A technology of low-temperature gas and process method, which is applied in the fields of production fluid, earth-moving drilling, isolation device, etc., can solve the problem of lack of attention, and achieve the effect of improving fracture system and rock mechanical properties, preventing fracture closure and improving implementation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

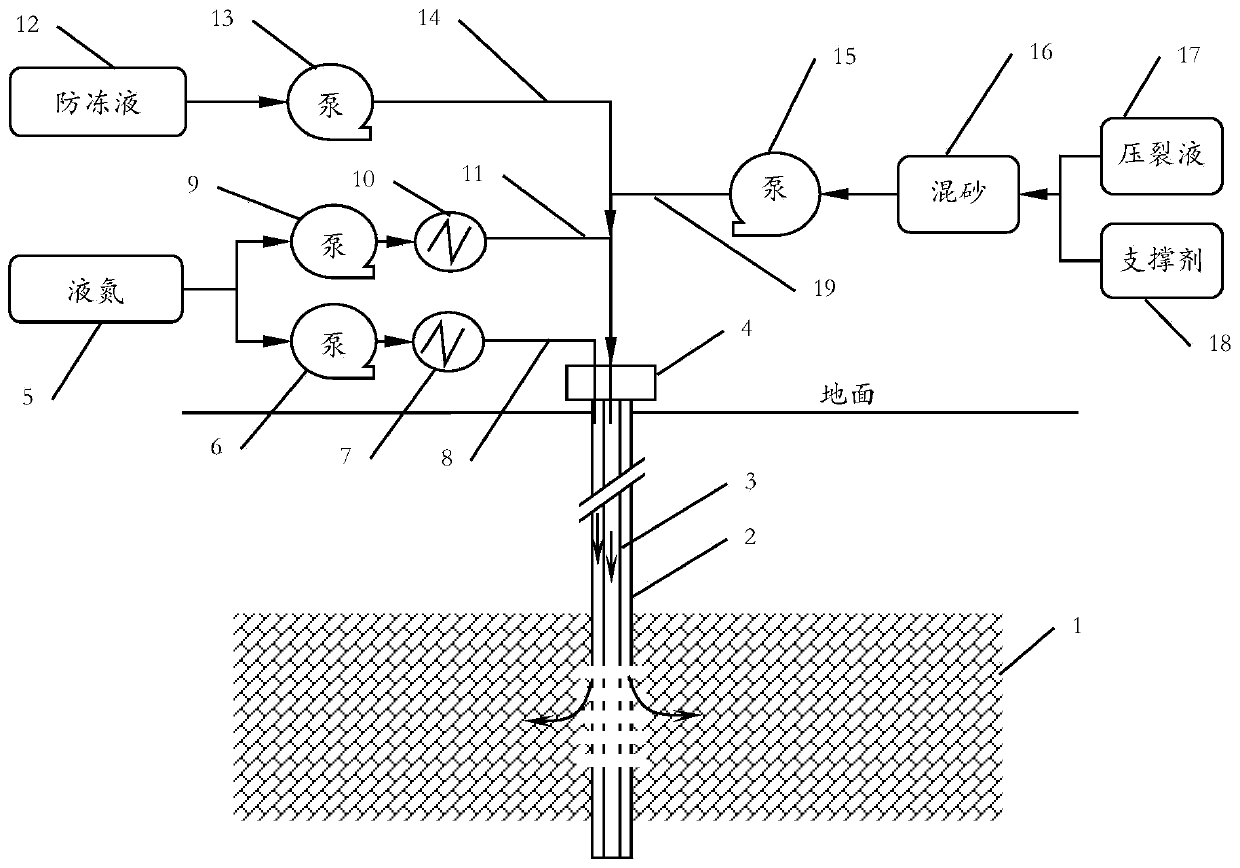

[0034] The present invention will be further described below in conjunction with accompanying drawing.

[0035] A method for low-temperature gas-assisted coalbed gas fracturing technology, the specific steps are as follows:

[0036] (1) Select a coalbed methane well, and select a glass fiber steel pipe with high strength, low temperature resistance and low thermal conductivity as the oil pipe 3;

[0037] (2) Pump the liquid nitrogen in the cryogenic gas storage tank 5 to the gas heating and temperature regulating device 7 through the cryogenic gas injection pump 6 and heat it to normal temperature 10-30°C, and then inject the liquid nitrogen into the oil pipe 3 and casing 2 through the gas injection line 8 Continuous injection in the annular space between the two, the injection speed is 30-60m 3 / min, in order to achieve the effect of thermal insulation and protective casing;

[0038] (3) Pump the liquid nitrogen in the low-temperature gas storage tank 5 to the gas heating a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com