Method for improving drum index of vanadium-titanium magnetite sinter

A vanadium-titanium sinter and drum index technology, applied in the field of iron ore powder sintering, can solve the problems of increased process costs, increased return ore, and increased sinter return

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Hereinafter, the method for increasing the drum index of vanadium-titanium sintered ore of the present invention will be described in detail with reference to examples.

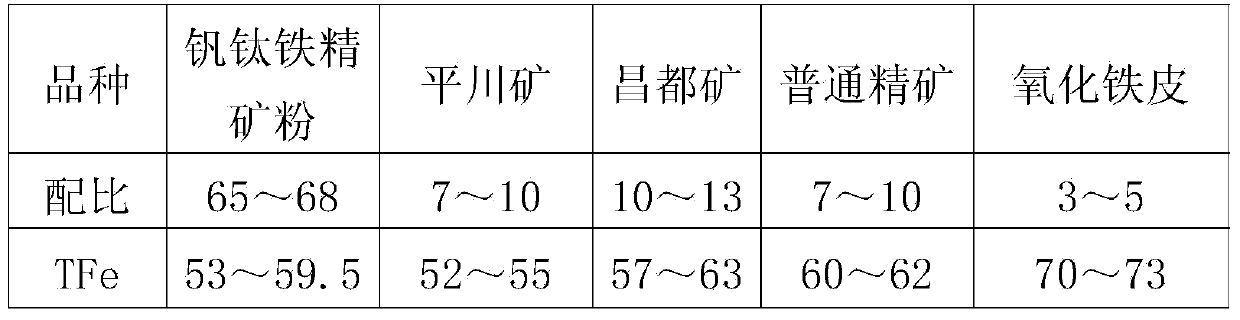

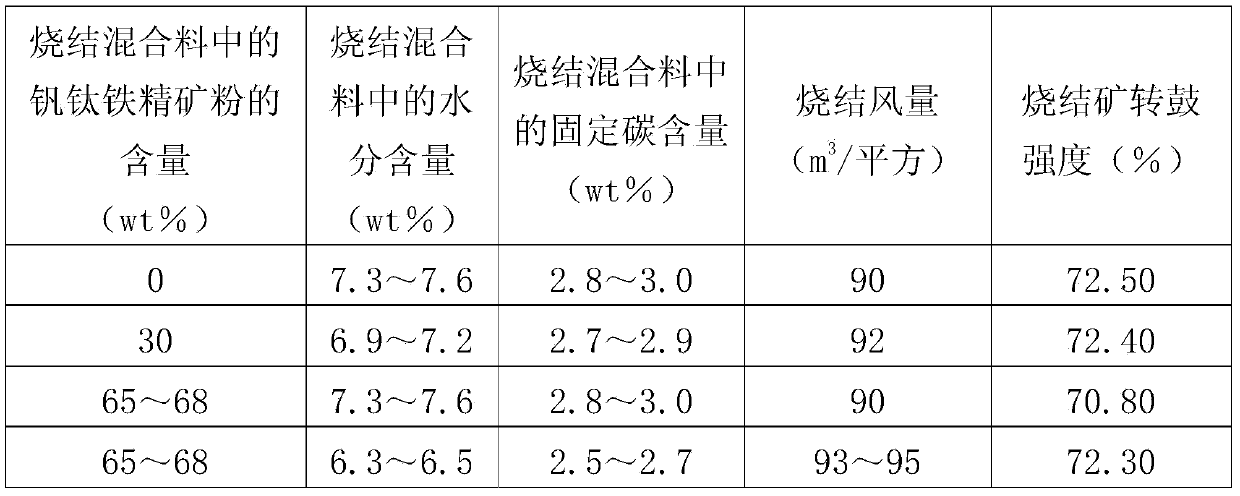

[0012] The method for improving the drum index of vanadium-titanium sintered ore according to the present invention includes reducing the moisture in the sintering mixture to 6.3-6.5wt%, and increasing the air volume during sintering to 93-95m 3 / square, and reduce the fixed carbon content in the sintering mixture to 2.5-2.7wt%, wherein, the sintering mixture of vanadium-titanium sintered ore includes 65-68wt% vanadium-titanium-iron ore concentrate powder. According to an embodiment of the present invention, the TiO in the vanadium-titanium iron ore concentrate powder 2 The content is 10-12wt%. The chemical composition of the vanadium-titanium iron ore concentrate powder is shown in Table 1, and the proportioning ratio of the sintering mixture is shown in Table 2.

[0013] Table 1 Main chemical compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com