Economical method for preparing carbon-containing pellet, carbon-containing pellet prepared through method and smelting process of carbon-containing pellet

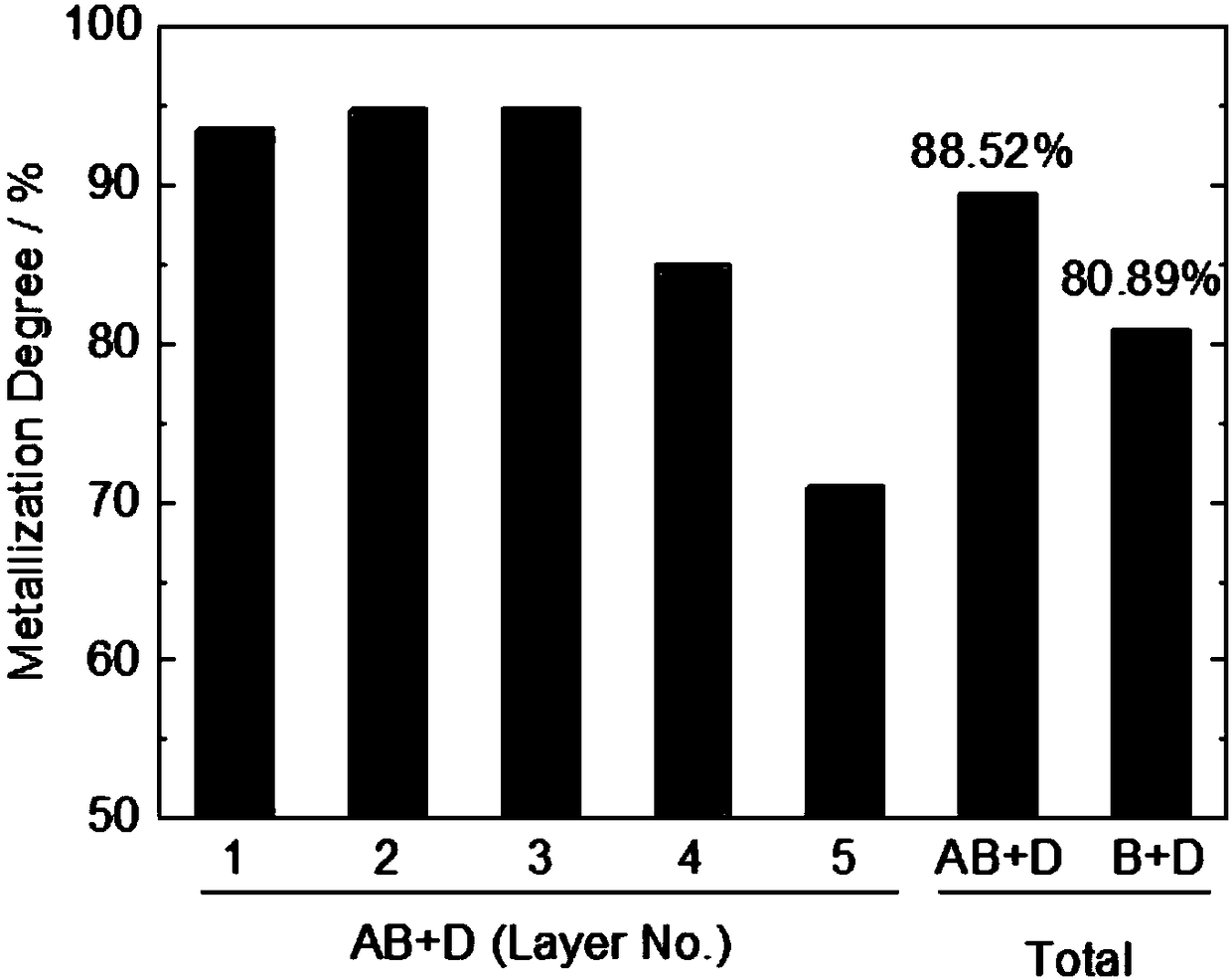

A technology of carbon pellets and pellets, applied in the field of metallurgy, can solve the problems of incompatibility between strength and metallization rate, low level of material utilization, complicated production process, etc., to avoid deterioration of heat transfer conditions, eliminate the tendency of bursting, The effect of improving the metallization rate and strength of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] This embodiment discloses an economical method for preparing carbon-containing pellets, comprising the following steps:

[0035] Step 1: dividing the hematite powder used for preparing carbon-containing pellets into a first hematite powder and a second hematite powder according to a mass ratio of 1:1;

[0036] The first ore powder and the second ore powder in step 1 of this embodiment are the same hematite powder, certainly in the present invention, whether the first hematite powder and the second hematite powder are the same hematite The powder is not limited, so in practical application, the first hematite powder and the second hematite powder can be two different hematite powders.

[0037] Step 2: Fe in the first hematite powder 2 o 3 converted to Fe 3 o 4 , to obtain magnetite powder;

[0038] In step 2 in this embodiment, the first hematite powder is processed to obtain magnetite powder with higher quality.

[0039] Step 3: the magnetite powder obtained in st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com