Umbrella water-based ink for satin fabrics and coating method of water-based ink

A water-based ink and fabric technology, applied in the field of umbrella surface processing and umbrella making, can solve the problems of water-based ink patterns that are difficult to dry quickly, the pattern adhesion fastness is not up to standard, and difficult to color, so as to reduce the residue of toxic chemicals on the umbrella surface and improve the Production environment, color stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] A kind of umbrella surface coating method of the present invention, carry out according to the following steps:

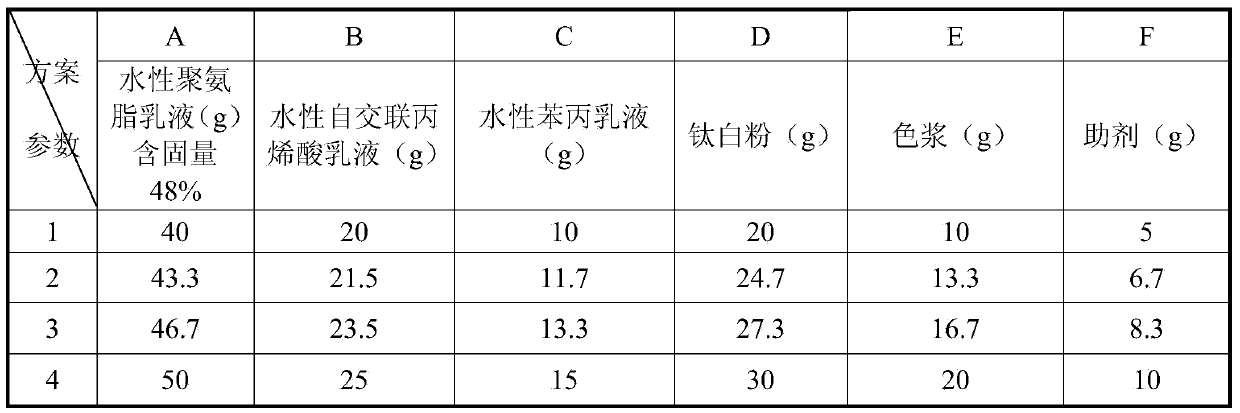

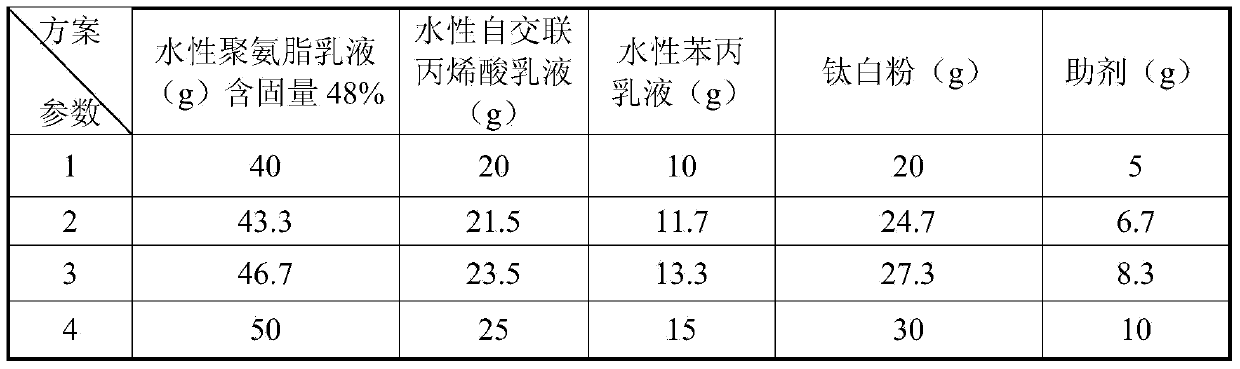

[0034] 1) According to the weight ratio, select 40-50 parts of water-based polyurethane emulsion, 20-25 parts of water-based self-crosslinking acrylic emulsion, 10-15 parts of water-based styrene-acrylic emulsion and 5-10 parts of additives to prepare corresponding transparent and colorless basic water-based inks spare;

[0035] 2) Select 20-30 parts of titanium dioxide and / or 10-20 parts of color paste according to the color required for color registration, and mix it with transparent colorless basic water-based ink to form water-based ink of corresponding color for later use;

[0036] 3) According to the coloring sequence, apply one of the prepared water-based inks to the umbrella surface;

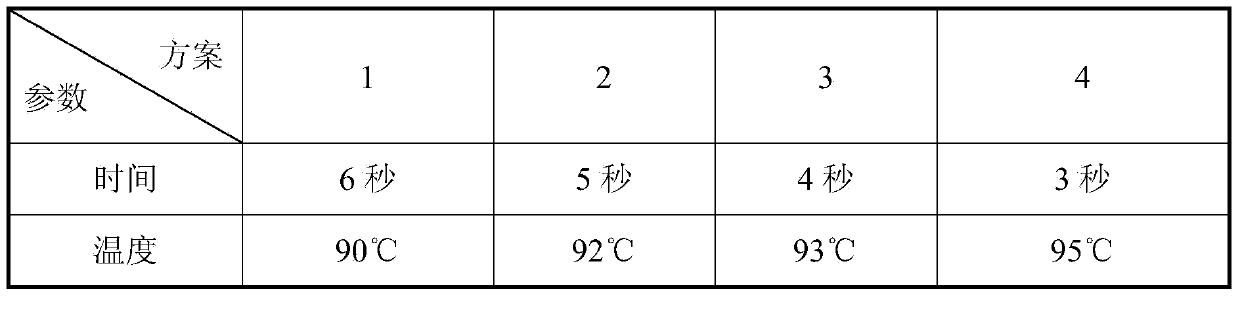

[0037] 4) Quickly flash-dry the coated umbrella surface within 6-10 seconds after the umbrella surface is coated, the flash-drying time is 3-6 seconds, and the flash-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com