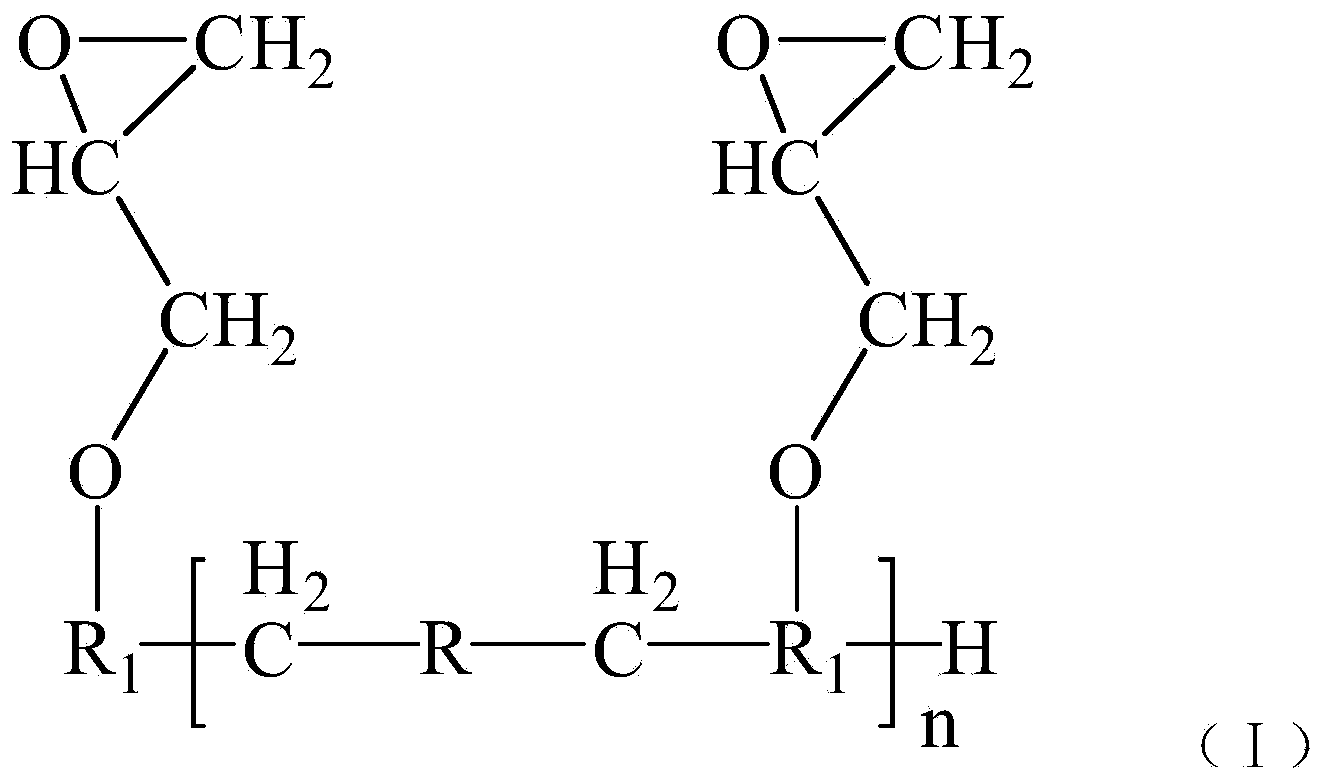

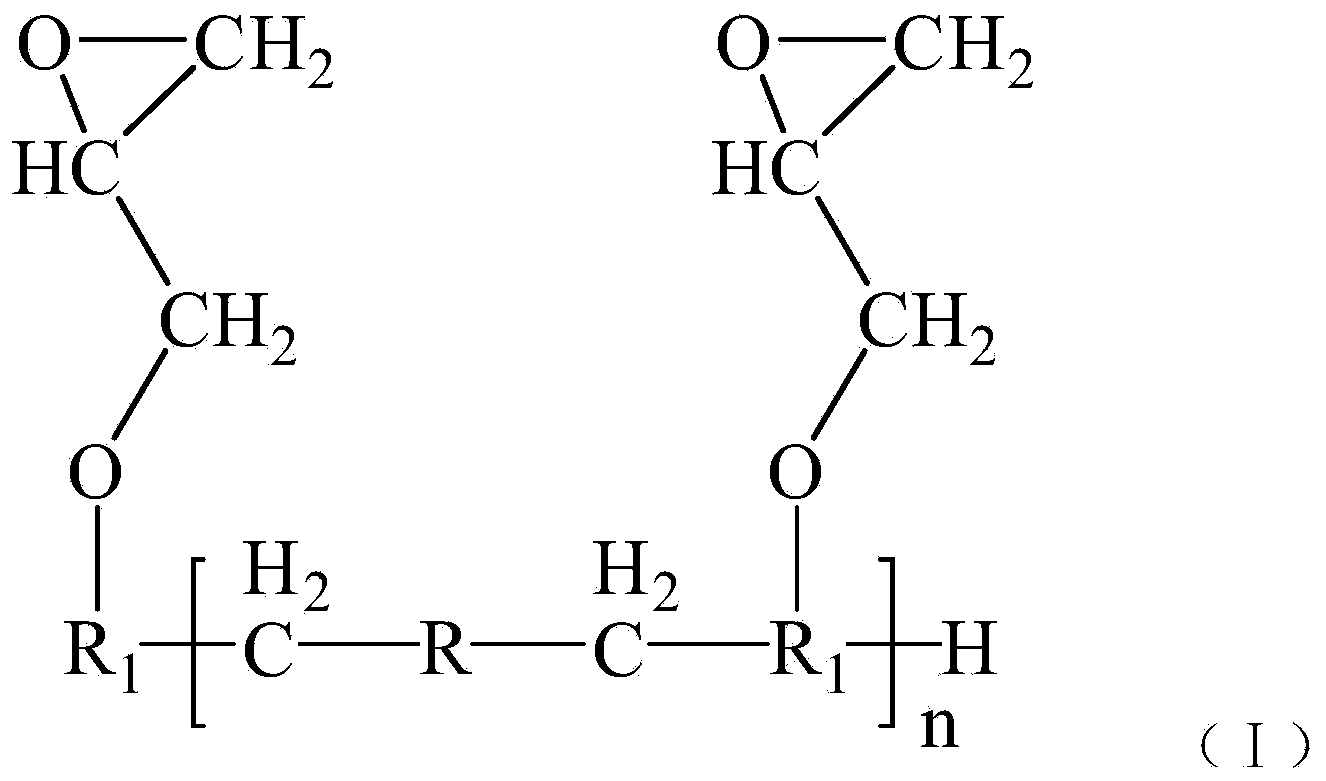

Cyanate resin composition and application thereof

A technology of cyanate ester resin and cyanate ester prepolymer, which can be applied to other household appliances, synthetic resin layered products, applications, etc., and can solve the problems of increased resin melt viscosity and decreased processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

[0057] Synthesis example 1: Synthesis of naphthyl aralkyl type phenolic resin

[0058] Add 46 g of β-naphthol, 271 g of phenol, 215 g of dichloromethylnaphthalene and 300 g of chlorobenzene into the flask, slowly heat up and dissolve while stirring under nitrogen protection, and react at about 80° C. for 2 hours. Then, while distilling off chlorobenzene, the temperature was raised to 180°C, and the reaction was carried out at 180°C for 1 hour. After the reaction, the solvent and unreacted monomers were removed by distillation under reduced pressure to obtain a brown naphthyl aralkyl type phenolic resin. From the analysis of recovered unreacted monomers, the molar ratio of β-naphthol / (β-naphthol+phenol) entering the resin was 0.23.

Synthetic example 2

[0059] Synthesis example 2: Synthesis of naphthyl aralkyl type phenolic resin

[0060] Add 96 g of β-naphthol, 251 g of phenol, 150 g of dichloromethylnaphthalene and 450 g of chlorobenzene into the flask, slowly heat up and dissolve while stirring under nitrogen protection, and react at about 80° C. for 2 hours. Then, while distilling off chlorobenzene, the temperature was raised to 180°C, and the reaction was carried out at 180°C for 1 hour. After the reaction, the solvent and unreacted monomers were removed by distillation under reduced pressure to obtain a brown naphthyl aralkyl type phenolic resin. From the analysis of recovered unreacted monomers, the molar ratio of β-naphthol / (β-naphthol+phenol) entering the resin was 0.50.

Synthetic example 3

[0061] Synthesis example 3: Synthesis of naphthyl aralkyl type phenolic resin

[0062] Add 224g of β-naphthol, 272g of phenol, 100g of dichloromethylnaphthalene and 300g of chlorobenzene into the flask, slowly heat up and dissolve while stirring under nitrogen protection, and react at about 80°C for 2 hours. Then, while distilling off chlorobenzene, the temperature was raised to 180°C, and the reaction was carried out at 180°C for 1 hour. After the reaction, the solvent and unreacted monomers were removed by distillation under reduced pressure to obtain a brown naphthyl aralkyl type phenolic resin. From the analysis of recovered unreacted monomers, the molar ratio of β-naphthol / (β-naphthol+phenol) entering the resin was 0.70.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt viscosity | aaaaa | aaaaa |

| Melt viscosity | aaaaa | aaaaa |

| Melt viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com