A method and device for constant temperature digital controlled ultrasonic cleaning

An ultrasonic and ultrasonic technology, applied in the field of ultrasonic cleaning, can solve the problems of increased volume and cost of ultrasonic cleaners, and achieve the effects of easy popularization, improved precision, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The object of the present invention is to provide a small volume, low cost, precise control method and device for constant temperature numerically controlled ultrasonic cleaning, so as to overcome the defects in the prior art and meet the needs of the market.

[0030] The present invention will be further described below in conjunction with accompanying drawing:

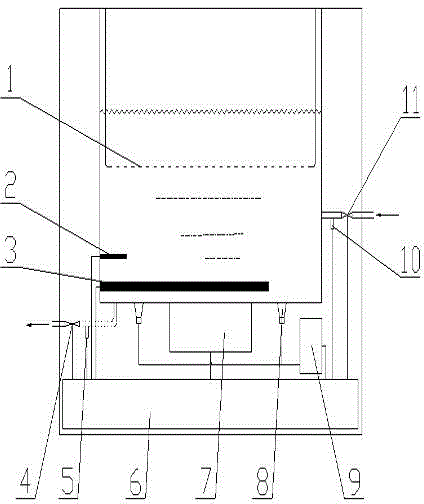

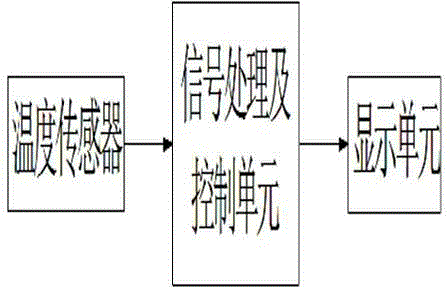

[0031] see figure 1 with figure 2 , a kind of constant temperature numerical control ultrasonic cleaning method of the present invention, comprises the following steps:

[0032] (1) Start the device. The system automatically adds low-temperature ultrasonic liquid to the set amount through the joint control of the electronically controlled liquid inlet valve 11 and the second flowmeter 10. During this process, the temperature sensor 2 controls the temperature of the low-temperature ultrasonic liquid. Transmit to PLC control system 6, and record.

[0033] (2) After the low-temperature ultrasonic liquid is ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com