Edible oil and fat product taking sterol saponins as raw materials

A technology for edible oil and sterol saponins, which is applied in the field of edible oil and fat products and its processing, can solve the problems of unmentioned methods and application research of edible oil and fat production, unstable form, etc., and achieves the effect of improving health value and reducing content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1%-8% diosgenin (purity 98%), mixed into oil and stirred at a specific temperature of 90-100°C until a transparent solution is obtained. Add soybean oil and dioscin in a 25ml small beaker, the total mass is 15g, wherein the diosgenin content is variable. The preparation conditions are: stirring until the temperature reaches 100°C; continuous stirring for 15 minutes to obtain a transparent solution; rapid cooling of the solution at a temperature of -40°C, stirring at a speed of 120r / min for 90s; static storage at room temperature solution for 3 days;

[0028] Table 1 shows the results of measuring the hardness of this solution containing different amounts of diosgenin.

[0029] Table 1

[0030]

[0031] It can be seen from this table that when the content of diosgenin is increased, the hardness decreases first and then increases.

Embodiment 2

[0033] In this series of experiments, the storage days of the product after cooling: 1-3-6 days,

[0034] The total content of diosgenin is 6%, and other constant conditions have been clarified in Example 1. The texture is measured at room temperature, and the results obtained are shown in the following table:

[0035] Table 2

[0036]

[0037] It can be seen from this table that as the storage days increase, the hardness shows a decreasing trend.

Embodiment 3

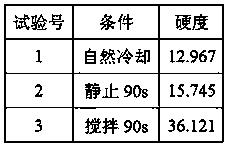

[0039] In this series of experiments, the variables are:

[0040] Cool the liquid heated until it becomes transparent, or quickly transfer it to -40°C for 90s, or quickly transfer it to -40°C and stir it at 120r / min for 90s. The ratio is 3:1, other conditions have been clarified in Example 1, the resulting hardness is shown in the table below:

[0041] table 3

[0042]

[0043] It can be seen from the table that the lower the treatment temperature, the greater the hardness, and the greater the hardness of the stirring effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com