Brush type sealing and fingertip sealing combined seal

A fingertip sealing and composite sealing technology, applied in the direction of preventing leakage, engine components, machines/engines, etc., can solve the sealing failure, do not meet the development trend of lightweight and miniaturization of aero-engines, increase the weight of seals and all Occupy space and other issues to achieve the effect of high pressure bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

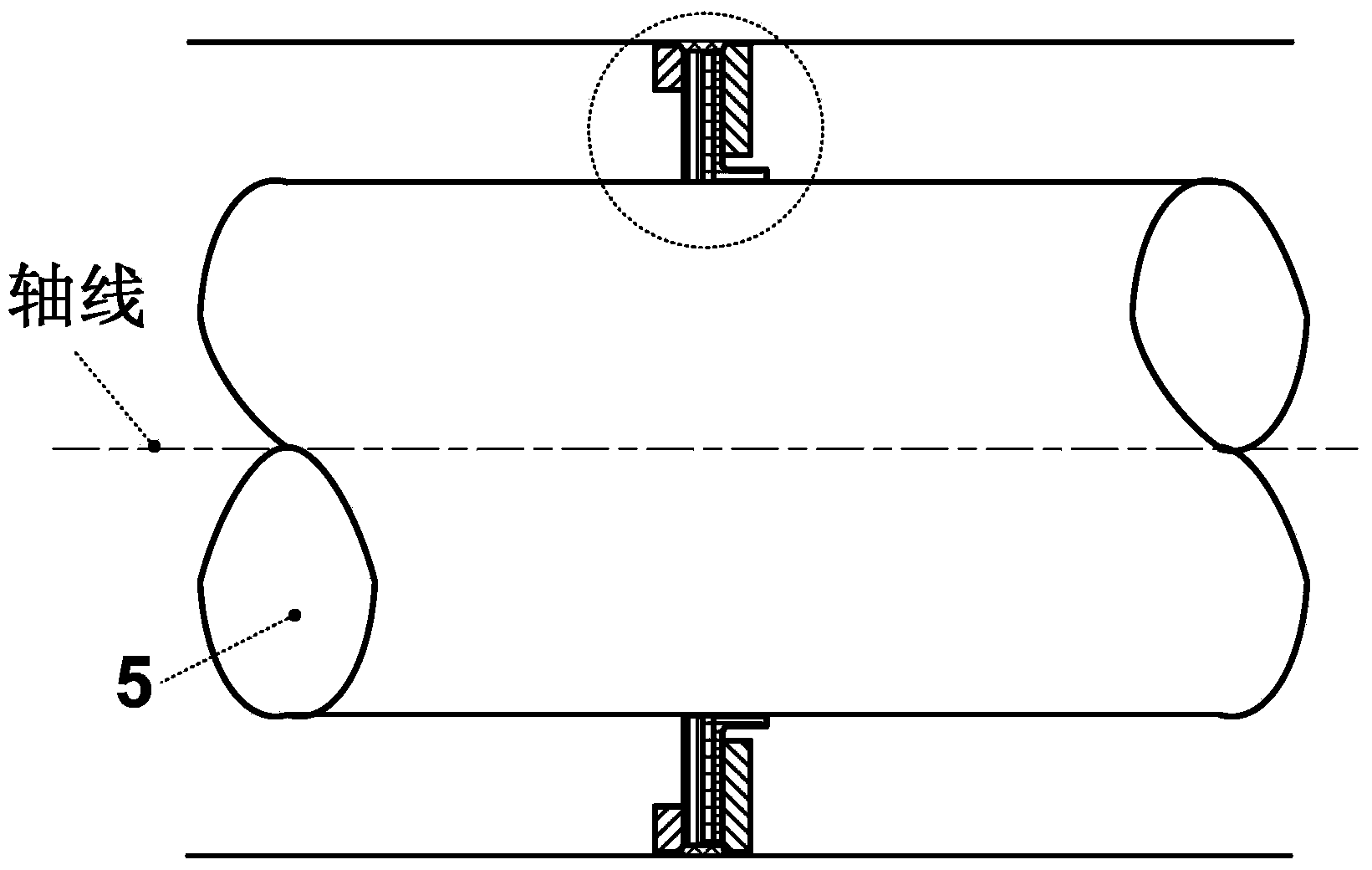

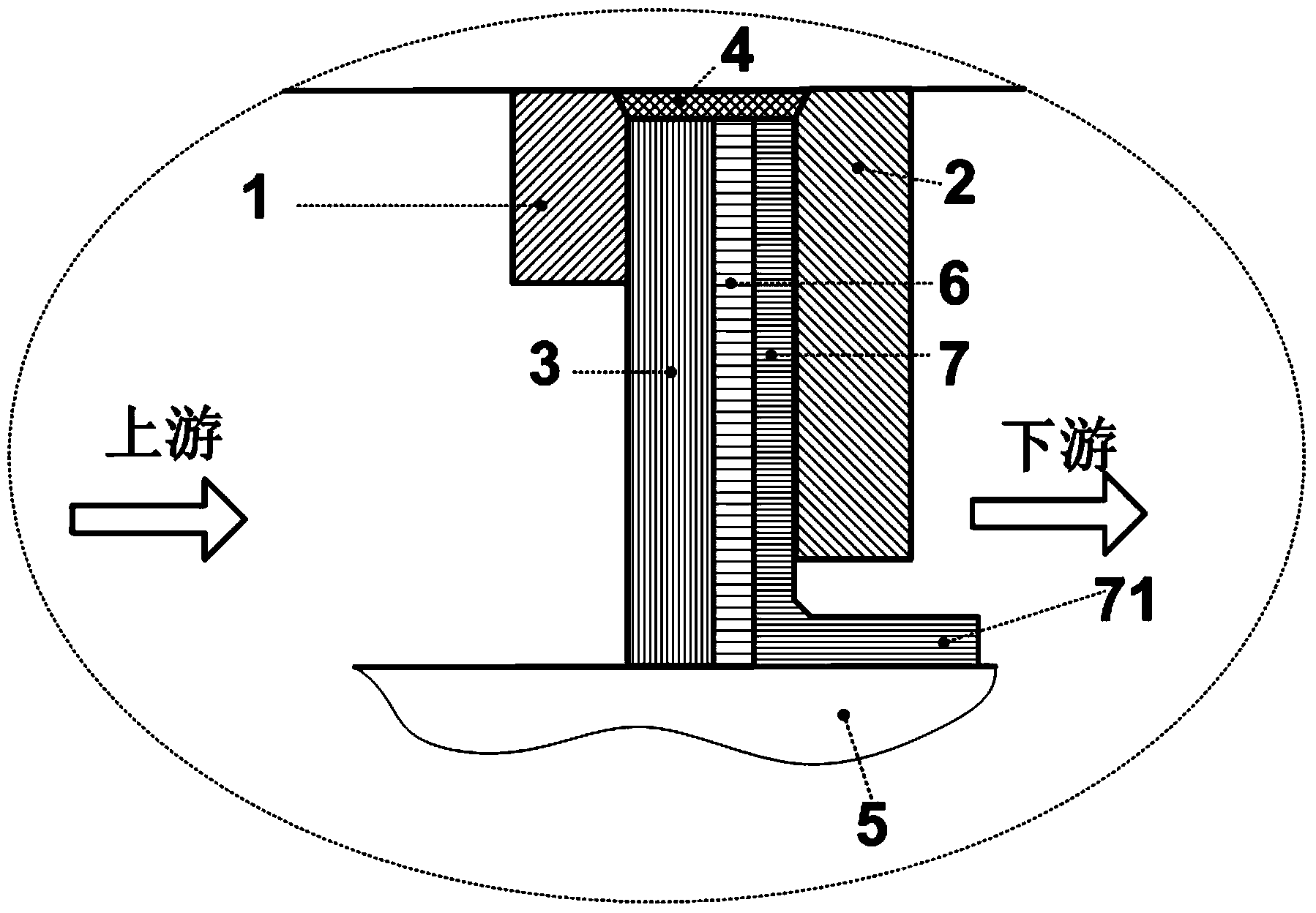

[0028] figure 1 and Figure 1A It is a schematic diagram of Embodiment 1 of the present invention, a composite seal of brush seal-fingertip seal, the total thickness in the axial direction is generally not more than 2mm, including front baffle 1, rear baffle 2, brush bundle 3, welding zone 4. The rotor 5 and the fingertip seal are low-pressure fingertip seals 7 or are composed of high-pressure fingertip seals 6 and low-pressure fingertip seals 7; the low-pressure fingertip seals 7 have an axial direction pointing downstream. The sealing shoe 71, there is a small gap between the axial sealing shoe 71 and the rotor 5, which can form a dynamic pressure effect and reduce frictional heat and wear.

Embodiment 2

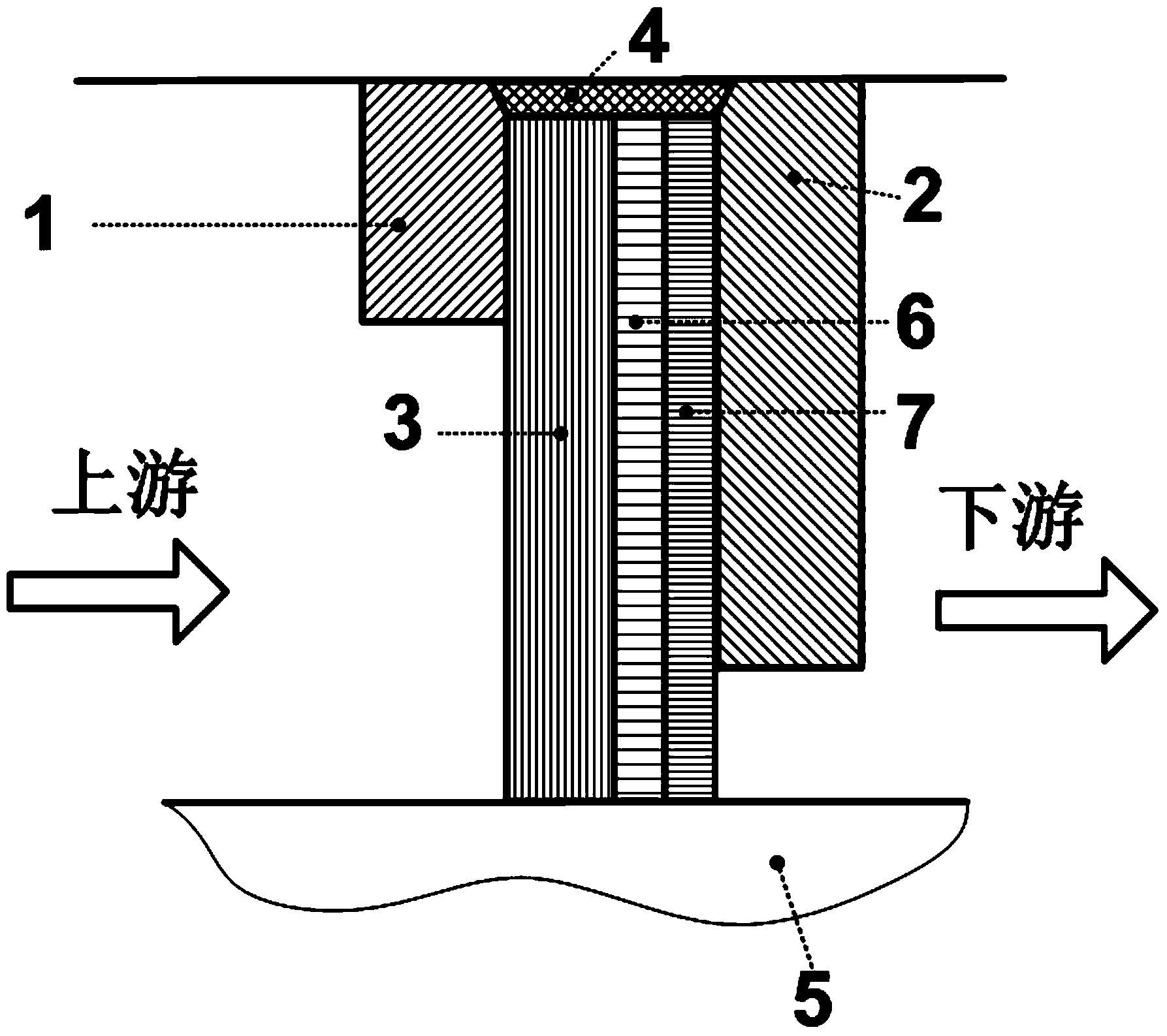

[0030] figure 2 It is a schematic diagram of Embodiment 2 of the present invention, a brush seal-fingertip seal composite seal, the total thickness in the axial direction is generally not more than 2mm, including the front baffle 1, the rear baffle 2, the brush bundle 3, and the welding zone 4. The rotor 5 and the fingertip seal are low-pressure fingertip seals 7 or are composed of high-voltage fingertip seals 6 and low-pressure fingertip seals 7; the feature is that the low-pressure fingertip seals 7 have no axial direction. Seal boot 71 .

Embodiment 3

[0032] image 3It is a schematic diagram of Embodiment 3 of the present invention, a composite seal of brush seal-fingertip seal, the total thickness in the axial direction is generally not more than 2mm, including front baffle 1, rear baffle 2, brush bundle 3, welding zone 4. The rotor 5 and the fingertip seals are low-pressure fingertip seals 7 or are composed of high-pressure fingertip seals 6 and low-pressure fingertip seals 7; Flow piece 8, the root of the outer diameter of the flow shielding piece 8 is generally fixed and clamped by the front baffle plate 1 and the brush filament bundle 3 through a welding process, and the inner diameter of the flow shielding piece 8 is larger than that of the front baffle plate 8. Between the inner diameter of the baffle plate 1 and the inner diameter of the rear baffle plate 2 ; the baffle plate 8 can reduce the disturbing effect of the upstream flow on the brush filament bundle 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com