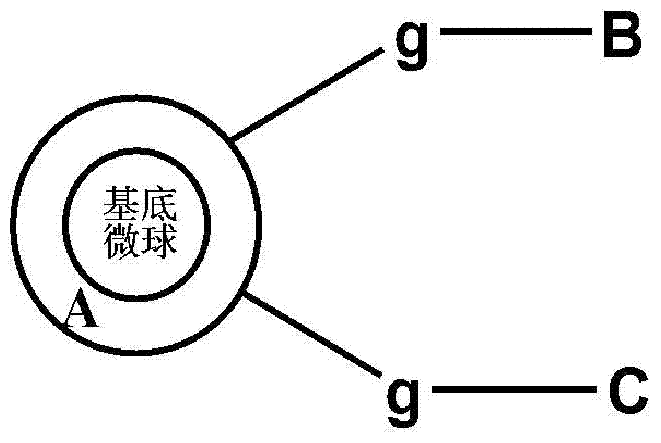

Water dispersible super-amphiphobic microsphere, preparation method and application thereof

A super-amphiphobic microsphere, dispersive technology, applied in the treatment of dyed polymer organic compounds, fibrous fillers, coatings, etc., can solve the problem of poor adhesion, high cost, and poor adhesion Strong and other problems, to achieve the effect of good scrub resistance and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

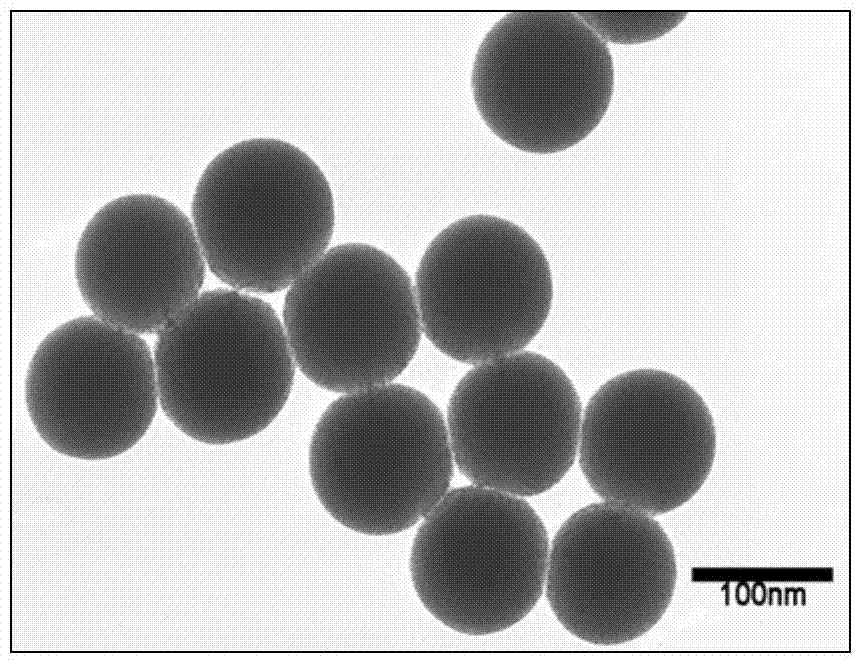

[0052] (1) Preparation of silica microspheres: Add 100ml of absolute ethanol and 3mL of ammonia water to a 250mL round-bottomed flask, then add 4mL of tetraethyl orthosilicate dropwise, react at 35°C for 24h, and wash the product with absolute ethanol Centrifugal washing three times, the obtained silica microspheres were lyophilized and vacuum-dried, and the final particle size of the obtained silica microspheres was 100±5nm. In addition, by adjusting the feed ratio of ammonia water and tetraethyl orthosilicate, 200±5nm, 350 The silicon dioxide of ± 5nm is used in embodiment 2, embodiment 3 respectively.

[0053] (2) Preparation of epoxy resin-coated microspheres: Dissolve polyglycidyl methacrylate (molecular weight 1000) in solvent E to prepare epoxy resin solution, disperse silica microspheres in solvent G, and ultrasonically Treat for 1 hour to obtain a microsphere dispersion, continue to add the epoxy resin solution dropwise to the microsphere dispersion at a rate of 0.2mL...

Embodiment 2

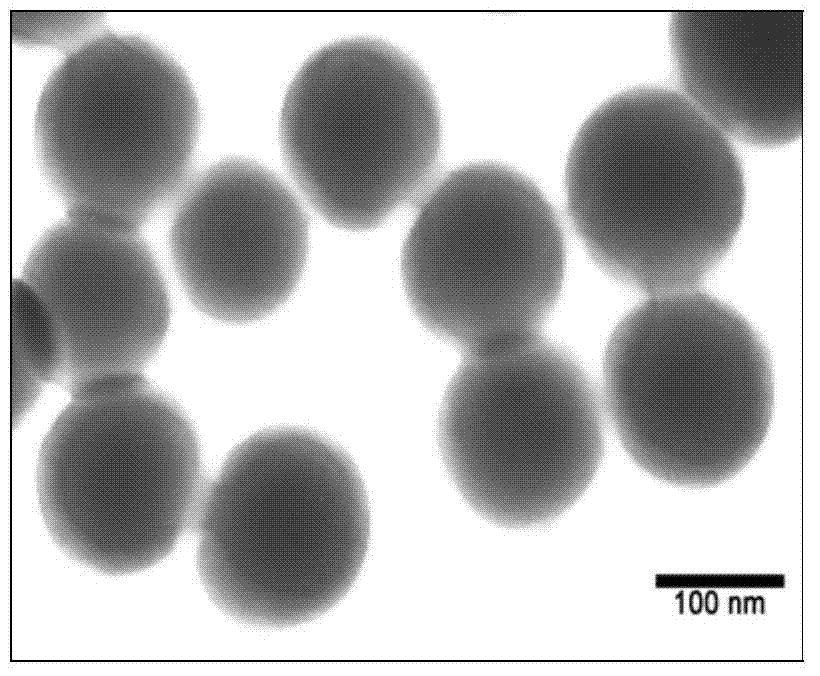

[0067] (1) Preparation of epoxy resin-coated microspheres: Dissolve polypropylene glycidyl ether in solvent E to prepare epoxy resin solution, disperse silica microspheres (200±5nm) in solvent G, and ultrasonically Treat for 1 hour to obtain a microsphere dispersion, continue to ultrasonically add the epoxy resin solution dropwise to the microsphere dispersion at a rate of 5mL / min, continue ultrasonication for 180min, remove most of the solvent by rotary evaporation, and place the product at 130 Heat treatment in a vacuum oven at ℃ for 20 minutes. After the product is cooled, add solvent E to re-disperse, centrifuge and wash 4 times, and dry the product in vacuum at room temperature to obtain epoxy resin-coated microspheres;

[0068]Solvent E and G are dioxane; the mass percent concentration of polypropylene glycidyl ether solution and microsphere dispersion is 10% and 5% respectively; the mass ratio of silica microspheres and epoxy resin is 1:10 .

[0069] (2) Preparation of...

Embodiment 3

[0078] (1) Preparation of epoxy resin-coated microspheres: Dissolve poly-o-cresyl glycidyl ether in solvent E to prepare epoxy resin solution, and disperse silica microspheres (with a particle size of 350±5nm) in solvent G During the process, ultrasonic treatment was performed for 1 hour to obtain a microsphere dispersion, and the epoxy resin solution was added dropwise to the microsphere dispersion at a speed of 1 mL / min while continuing to sonicate, and the ultrasonic solution was continued for 60 minutes, and the product was obtained by rotary evaporation to remove most of the solvent. Place it in a vacuum oven at 80°C for heat treatment for 40 minutes. After the product is cooled, add solvent E to redisperse it, wash it by centrifugation for 4 times, and dry the product in vacuum at room temperature to obtain epoxy resin-coated microspheres;

[0079] Solvents E and G are tetrahydrofuran and dimethylformamide respectively; the mass percent concentrations of poly-o-cresyl gly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com