Method for separating ABS (Acrylonitrile Butadiene Styrene) and PS (Poly Styrene) from waste mixed plastic and application of method

A mixed plastic and waste technology, applied in the field of waste plastic, can solve the problems of slow plastic dissolution, difficult separation of ABS and PS, unfriendly environment, etc., to achieve the effect of short production cycle and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

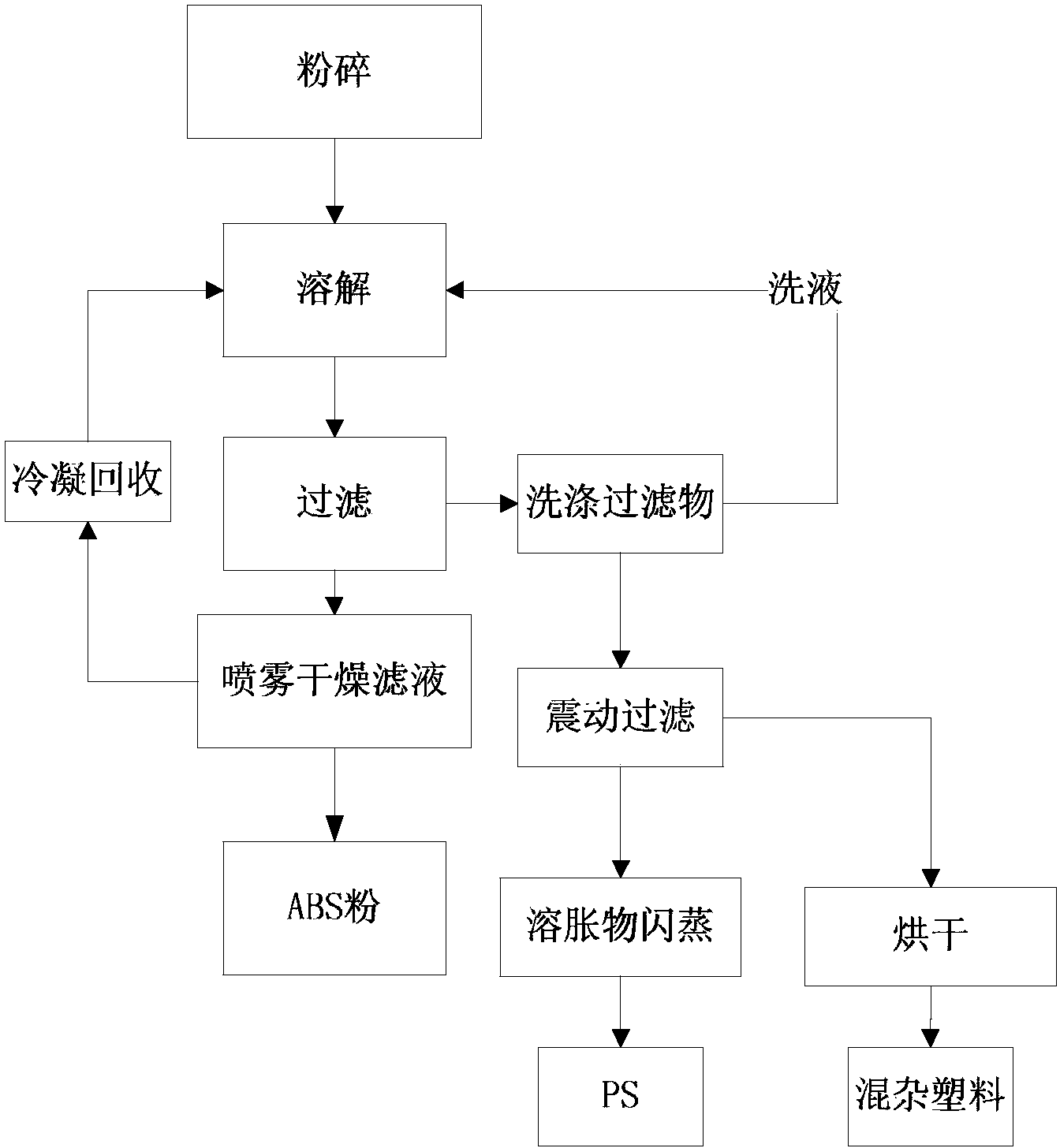

[0040] See the process flow figure 1 .

[0041] Add a solvent consisting of 95% by mass of industrial acetone and 5% by mass of n-hexane from the feeding port of a 300-liter three-port dissolution reactor, start stirring and mix the acetone and n-hexane evenly.

[0042] Heat the reaction kettle, and turn on the condensing circulating water of the solvent reflux system. When the temperature of the solvent rises to 40°C, add refrigerator waste mixed plastic with a particle size of less than 10mm into the reactor according to the weight ratio of solvent and refrigerator waste mixed plastic at 1:0.5, and stir and dissolve until the solid material no longer shrinks.

[0043] Put the plastic solution directly from the bottom of the reactor on a filter with a mesh size of 2 mm, and collect and filter the ABS solution. After the filtration is completed, the filtrate on the net is transferred to another three-port reaction kettle with a capacity of 240 liters as soon as possible.

...

Embodiment 2

[0050] See the process flow figure 1 .

[0051] Add a solvent consisting of 85% by mass of industrial acetone and 15% by mass of n-hexane from the feeding port of a 300-liter three-port dissolution reactor, start stirring and mix the acetone and n-hexane evenly.

[0052] Heat the reaction kettle, and turn on the condensing circulating water of the solvent reflux system. When the temperature of the solvent rises to 35°C, add refrigerator waste mixed plastic with a particle size of less than 10mm into the reactor according to the weight ratio of solvent and refrigerator waste mixed plastic at 1:0.3, and stir and dissolve until the solid material no longer shrinks.

[0053] Put the supernatant on a filter with a mesh size of 2 mm, and collect and filter the ABS solution. After the filtration is completed, the filtrate on the net is transferred to another three-port reaction kettle with a capacity of 240 liters as soon as possible.

[0054] After filtering the obtained ABS solu...

Embodiment 3

[0060] See the process flow figure 2 .

[0061] Add a solvent consisting of 90% by mass of industrial acetone and 10% by mass of n-hexane from the feeding port of a 300-liter three-port dissolution reactor, start stirring and mix the acetone and n-hexane evenly.

[0062] The waste and old mixed plastics of the refrigerator are crushed to a particle size of less than 10mm, and the obtained particles are processed by conventional air separation, and the air containing foam enters the foam treatment process. The particles that have been treated by winnowing are washed with water, filtered, dried and sedimented to remove sand. Get pre-processed refrigerator waste mixed plastic.

[0063] Heat the reaction kettle, and turn on the condensing circulating water of the solvent reflux system. When the temperature of the solvent rises to 38°C, add refrigerator waste mixed plastic with a particle size of 7mm to the reactor according to the weight ratio of solvent and refrigerator waste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com