Shear-type elastic wheel for rail transit vehicles

A technology for rail transit vehicles and elastic wheels, which is applied to the field of shear elastic wheels for rail transit vehicles, can solve the problems of increasing the difficulty of wheel production and manufacturing, large rubber vulcanization equipment, and high maintenance costs, so as to improve ride comfort and reduce Use and maintenance cost, reasonable structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

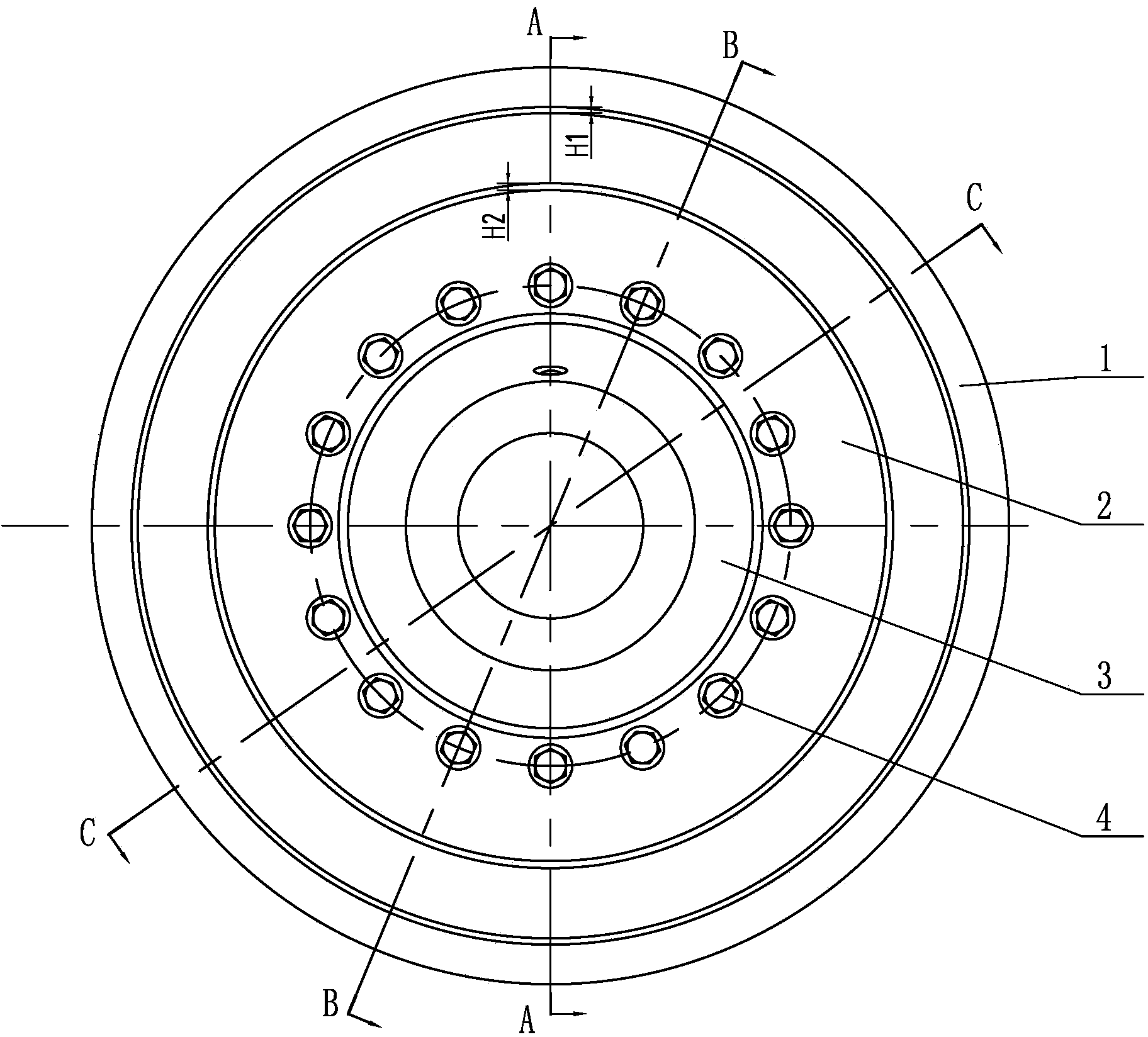

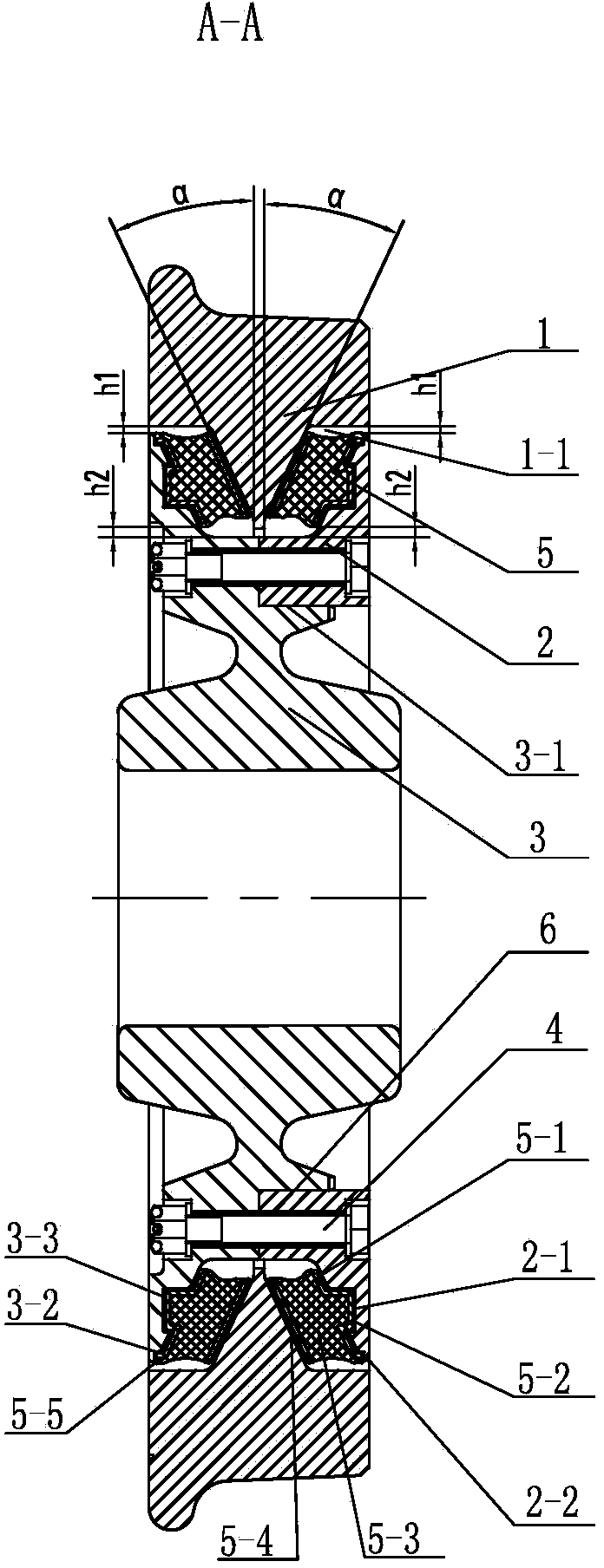

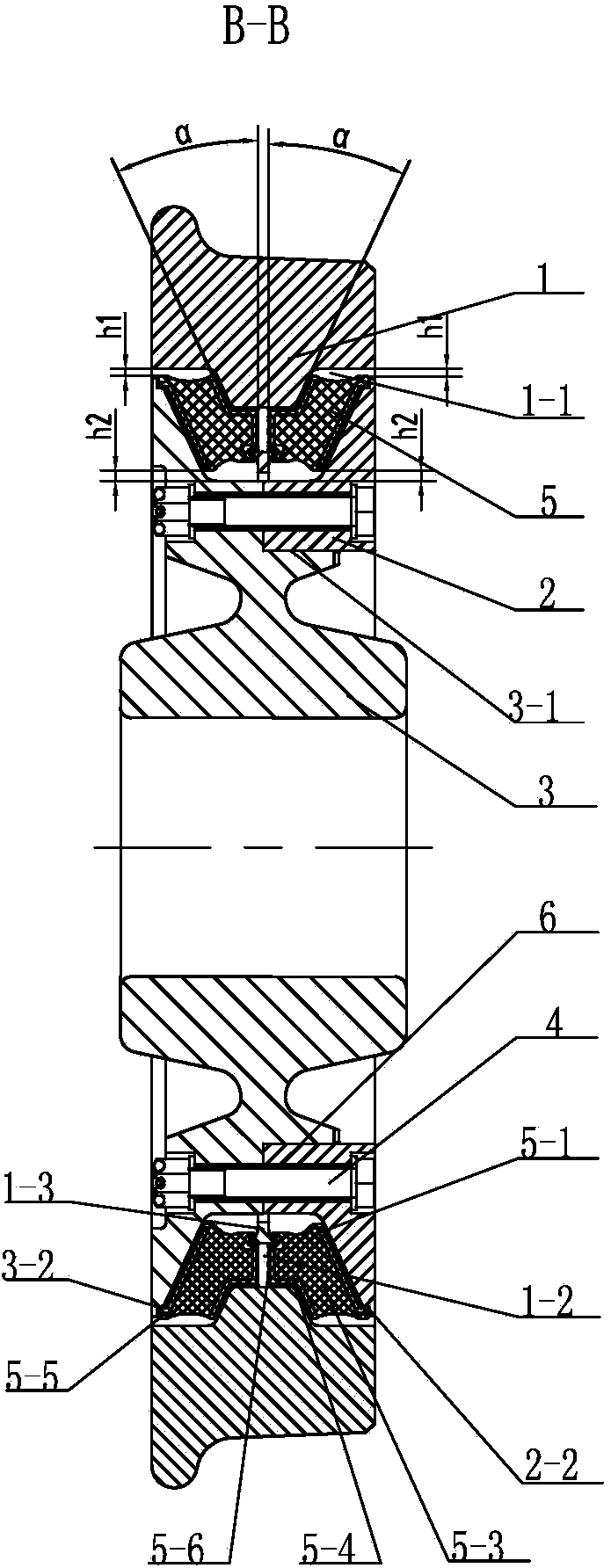

[0016] See Figure 1~4 As shown, the vehicle shear type elastic wheel of the present invention comprises a tire 1 with mounting ring grooves 1-1 on both sides, a wheel center 3 with a gap 3-1, a pressure ring 2 and two elastic discs 5, The ring 2 is set at the gap 3-1 of the wheel center 3 and is fastened to the wheel center 3. The tire 1, the pressure ring 2 and the wheel center 3 can be connected by more than four uniformly distributed fasteners 4. The ring 2 and the wheel center 3 are evenly arranged with 8 to 24 installation holes along their circumference, and the shaft sleeve 6 is installed in the installation holes. The fasteners 4 can be bolts and lock nuts, and each bolt is installed in the corresponding installation hole and Locking by a lock nut, or the present invention adopts a snap ring connection, and the pressure ring 2 is connected to the wheel center 3 through the snap ring, so that the tire 1, the wheel center 3, the pressure ring 2 and the elastic disc 5 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com