A kind of micro-bending device and method of clustered and combined mold sleeves

A micro-bending and combined technology, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of low precision of forming workpieces, high energy consumption of laser heating, and difficulties in mold manufacturing, so as to improve positioning efficiency and accuracy , Conducive to mass production, convenient selection of bolts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

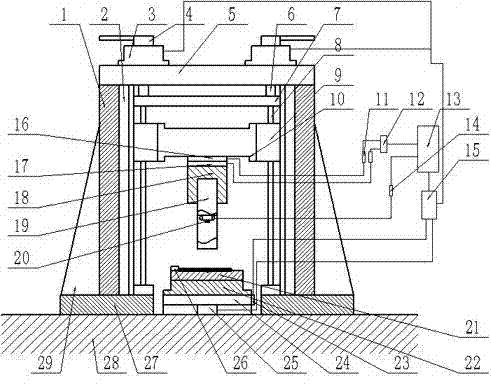

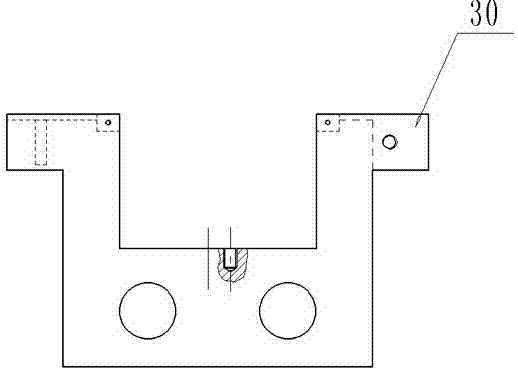

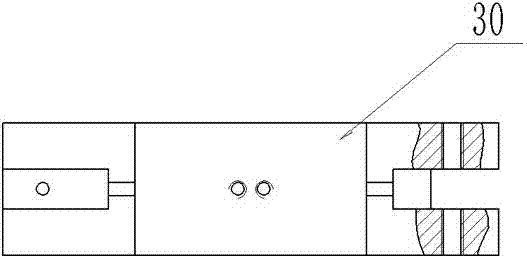

[0029] The devices and methods described will be described in detail below in conjunction with the accompanying drawings.

[0030] The forming device proposed by the present invention includes six parts: a mounting table 28, a translational loading workbench, a data acquisition system, a bundled and combined punch mold assembly 19, a die assembly and a control system. The power source is provided by the translational loading workbench, and the data acquisition system provides the information required for control. The mold set cluster combined punch assembly 19 and the die assembly complete the forming and bending. The control system mainly controls the displacement, speed and to medium. The details of each part will be introduced in detail in conjunction with the figure below.

[0031] combine figure 1 , the translational loading table consists of a fixed base 27, an angle iron fixed block 29, a loading frame 1, a square guide rail 2, a screw 8, a sliding panel 9, a fixing p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com