Double stator disk motor without rotor yoke

A disc-type motor and double-stator technology, which is applied in the direction of motors, electric vehicles, electrical components, etc., can solve the problems of slow punching process, difficult core manufacturing, and difficult winding of windings, so as to reduce manufacturing man-hours and improve slot Full rate, the effect of solving manufacturing difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

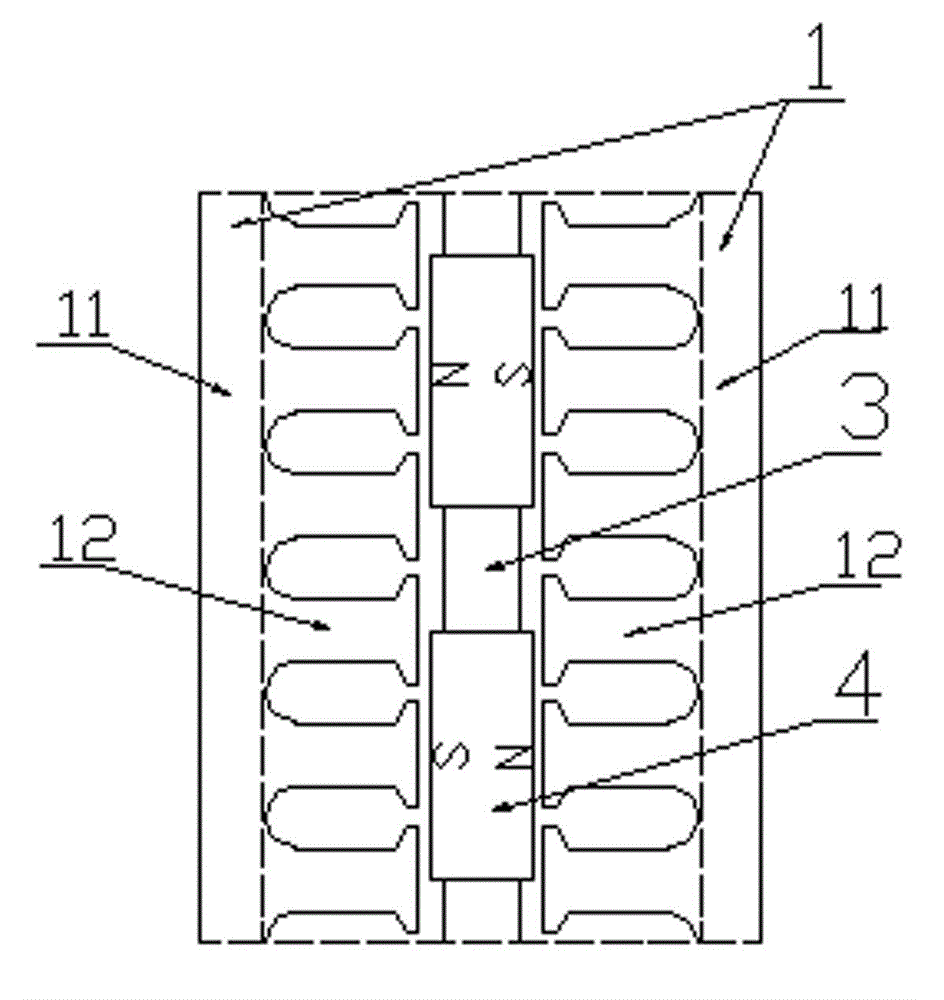

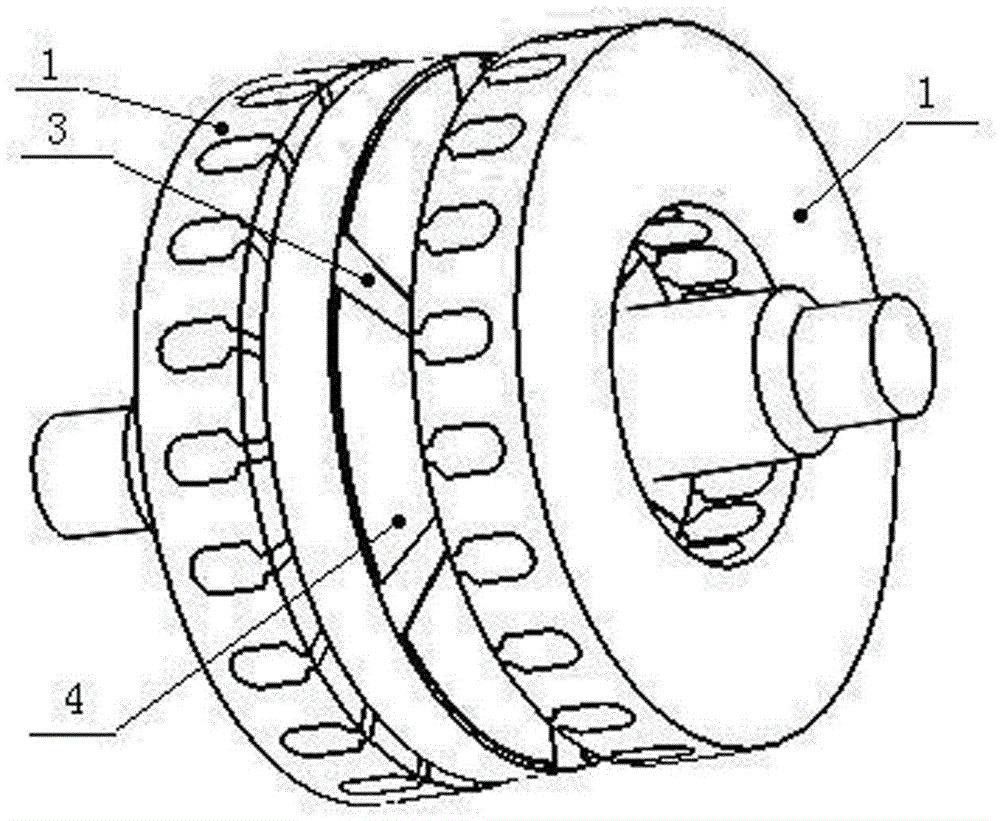

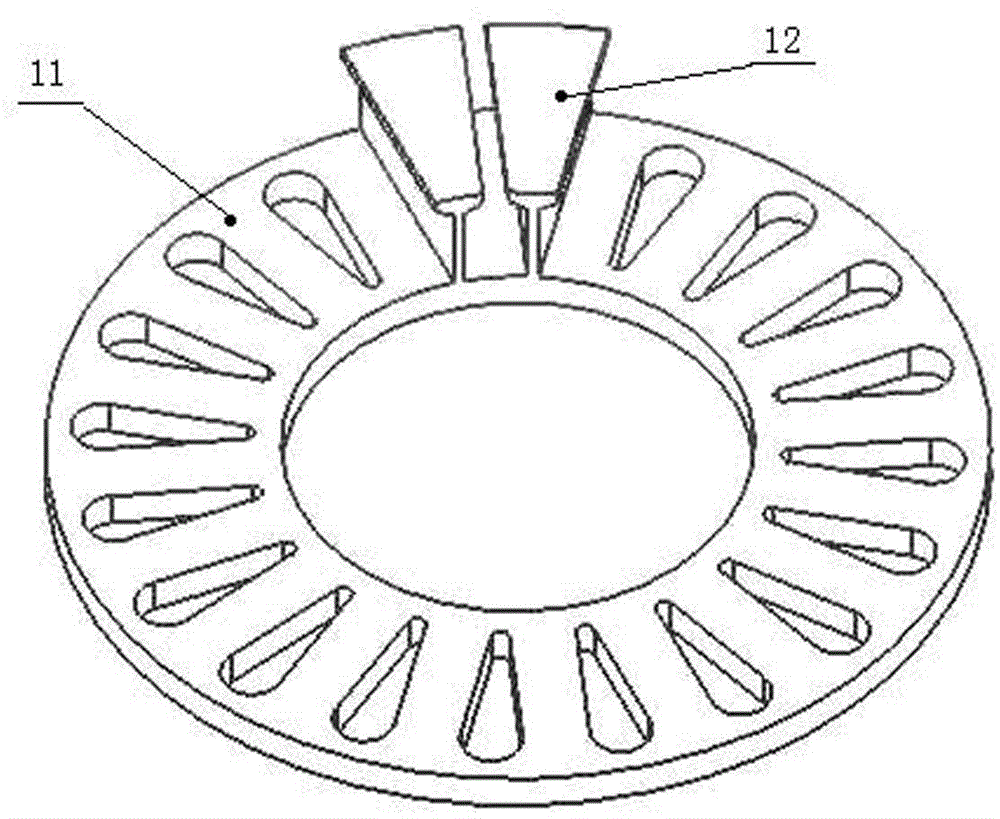

[0013] see figure 1 , 2 , 3. The present invention includes two stators 1 and a rotor disc 3, and the rotor disc is located between the two stators. The stator 1 is composed of a stator yoke 11 and an armature tooth 12. The stator yoke 11 adopts the traditional lamination method and is formed by laminating silicon steel sheets in the axial direction, and the armature tooth 12 is made of soft magnetic composite material (SMC). , the stator winding is wound on the armature teeth, and then fixed on the stator yoke. The rotor disk 3 is made of non-magnetic material, and the permanent magnets 4 are evenly embedded in the rotor disk, the direction of the magnetic poles of the permanent magnets is parallel to the axial direction, and the polarities of adjacent magnetic poles of the permanent magnets are opposite.

[0014] Such as figure 1 As shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com