Tensioning type micro-bending forming method and device

A tension-type, micro-bending technology, applied in forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of insufficient rigidity of the micro-bending punch, long forming cycle, and difficulty in mass production, etc., to achieve micro-bending forming Convenience and reliability, enhanced usability, and controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

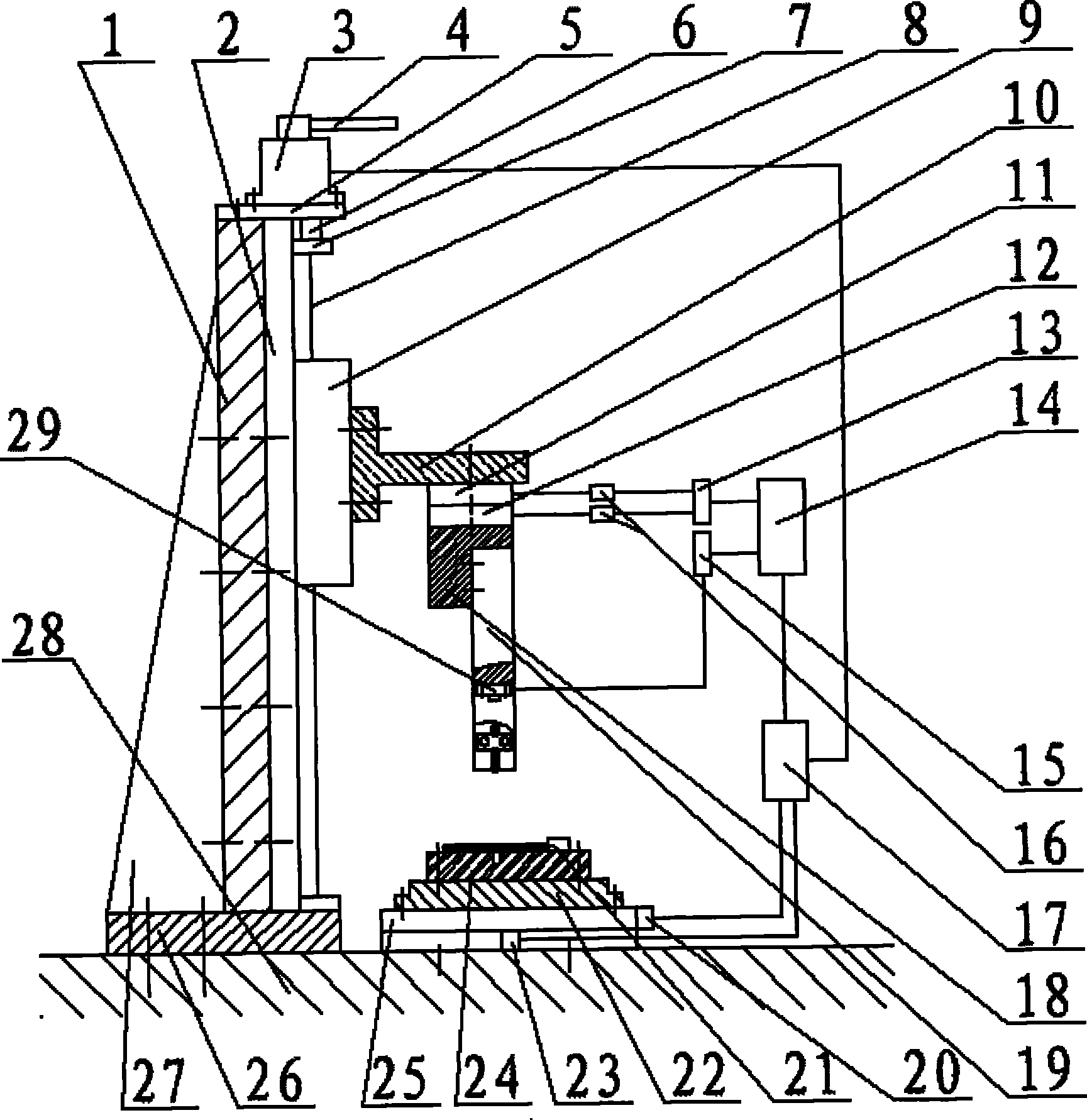

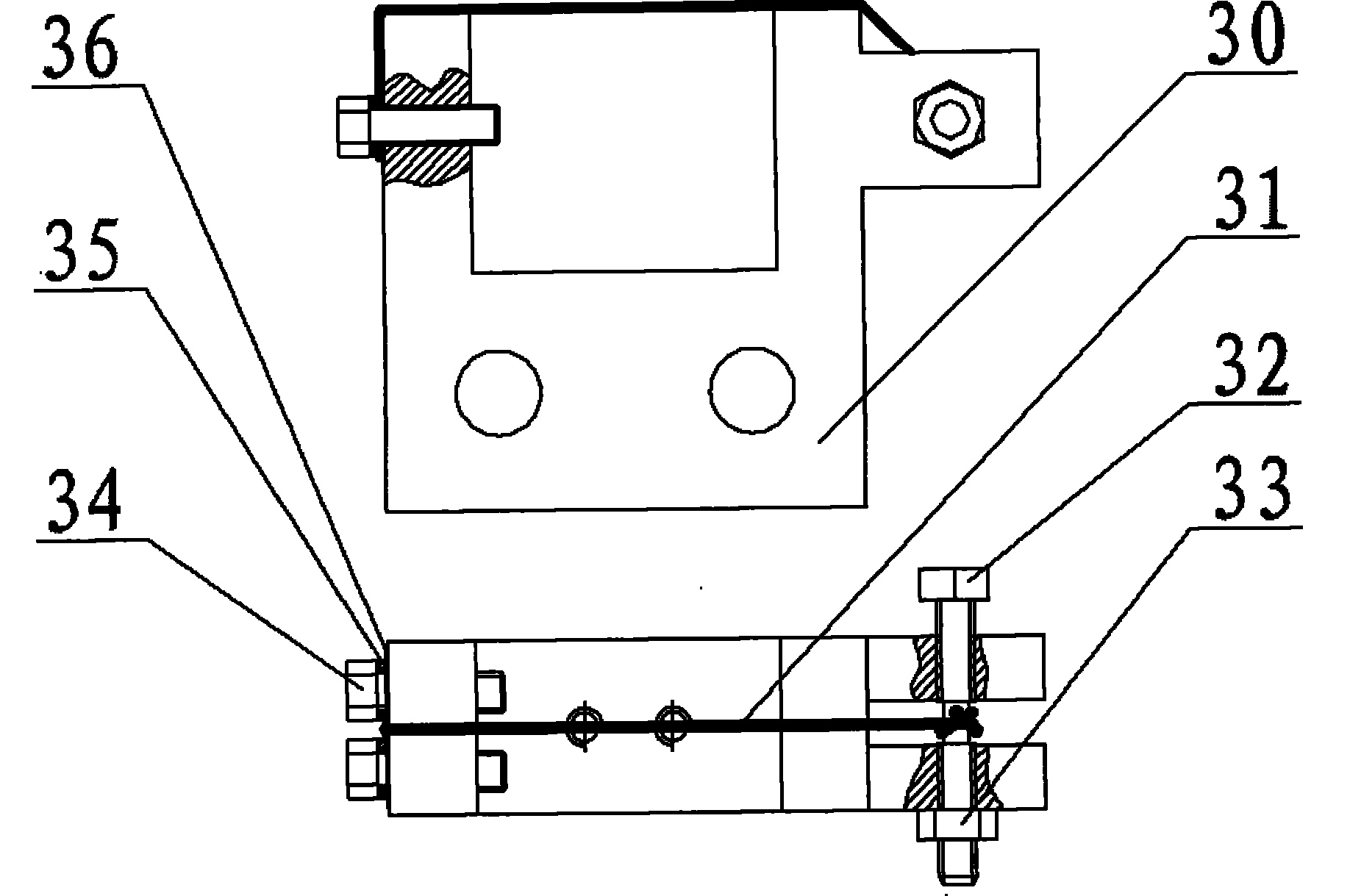

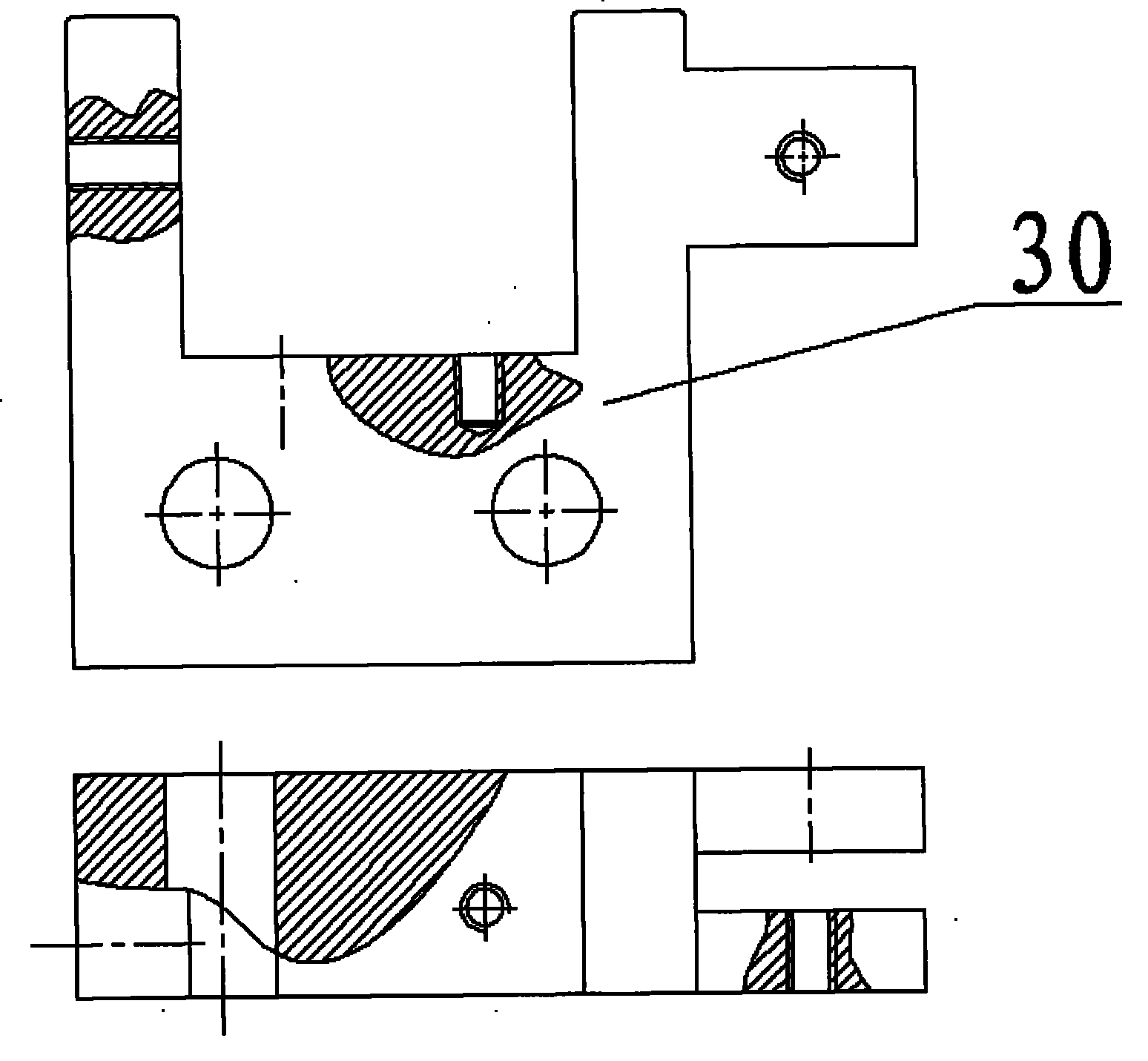

[0043] combine figure 1 , figure 2 and image 3 , the tension-type micro-bending forming method is as follows:

[0044] As required, the fixed base 26 is installed on the mounting table 28, then the angle iron fixed block 27 is installed on the fixed base 26, then the loading frame 1 is installed on the right side of the angle iron fixed block 27, and the sliding panel 9 is connected with the wire The bar 8 and the square guide rail 2 are installed on the loading frame 1, the fixed plate 7 and the shaft coupling 6 are installed on the leading screw 8, and the mounting plate 5 is installed on the loading frame 1, and the stepper motor I 3 is installed on the mounting plate 5 Then T-shaped plate 10 is installed on the sliding panel 9, displacement sensor 11 and force sensor 12 are installed below T-shaped plate 10, L-shaped plate 18 is installed below force sensor 12, connected by displacement sensor 11 and force sensor 12 Afterwards, through the transmitter 16, connect the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com