Preparing method of modified aluminum oxide dehydrant

A technology of alumina and dehydrating agent, applied in chemical instruments and methods, separation methods, other chemical processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A method for preparing modified alumina dehydrating agent. After mixing macroporous aluminum glue, macroporous silica gel, calcium oxide, zinc oxide and tianqing powder uniformly, they are kneaded, formed, pelletized, dried and calcined in sequence. , Impregnation, secondary drying, and secondary roasting to make finished products, which are used in the dehydration process before separating chlorine and oxygen from the mixed gas generated by the catalytic oxidation reaction of hydrogen chloride by the adsorption separation method; aluminum glue: silica gel: calcium oxide: zinc oxide: The mass ratio of Tian Qingfen is 70-82:7-14:0.5-2.0:5-10:5-10.

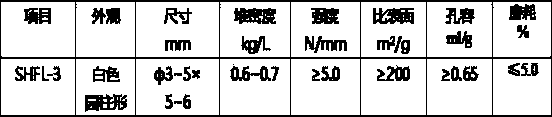

[0037] The physical properties of the modified alumina dehydrating agent are: size ф3~5×6mm, bulk density 0.6-0.7 kg / L, strength ≥5.0 N / mm, specific surface ≥200 m 2 / g, pore volume ≥0.65ml / g, abrasion ≤5.0%.

[0038] The chemical composition of the modified alumina dehydrating agent is: 75.0-82.0% Al 2 O 3 , 8.0-11.5% SiO 2 , 0.8...

Embodiment 2

[0047] A preparation method of modified alumina dehydrating agent, including: after mixing aluminum glue, silica gel, calcium oxide, zinc oxide and tianqing powder uniformly, then sequentially undergoing kneading, forming, pelletizing, one-time drying, one-time roasting and dipping , Secondary drying, secondary roasting to make the finished product, the mass ratio of aluminum glue: silica gel: calcium oxide: zinc oxide: Tianqing powder is 82:7:1:5:5.

[0048] In this embodiment, the chemical composition of the modified alumina dehydrating agent is: 75.0% Al 2 O 3 , 11.5% SiO 2 , 1.2% Na 2 O, 3.0% CaO, 9.0% ZnO, and 0.3% impurities.

[0049] In this embodiment, in the kneading process, deionized water is added to the mixture, and the mass of the added deionized water is 40% of the blend.

[0050] In this embodiment, in the pelletizing process, the extruded body is cut into pellets with a specification of Φ3×5 mm.

[0051] In this embodiment, in the primary drying process, the drying te...

Embodiment 3

[0057] A preparation method of modified alumina dehydrating agent, including: after mixing aluminum glue, silica gel, calcium oxide, zinc oxide and tianqing powder uniformly, then sequentially undergoing kneading, forming, pelletizing, one-time drying, one-time roasting and dipping , Secondary drying, secondary roasting to make finished products, the mass ratio of aluminum glue: silica gel: calcium oxide: zinc oxide: Tianqing powder is 70:14:2.0:6:8.

[0058] In this embodiment, the chemical composition of the modified alumina dehydrating agent is: 82.0% Al 2 O 3 , 8.0% SiO 2 , 0.8% Na 2 O, 1.6% CaO, 7.4% ZnO, 0.2% impurity.

[0059] In this embodiment, in the kneading process, deionized water is added to the mixture, and the mass of the added deionized water is 65% of the blend.

[0060] In this embodiment, in the pelletizing process, the extruded green body is cut into pellets with a specification of Φ5×6 mm.

[0061] In this embodiment, in the primary drying process, the drying tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com