LED light source packaging structure

A technology of LED light source and packaging structure, which is applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problems of low heat dissipation capacity, resin aging, complex packaging process of LED light source module, etc., and achieve high heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

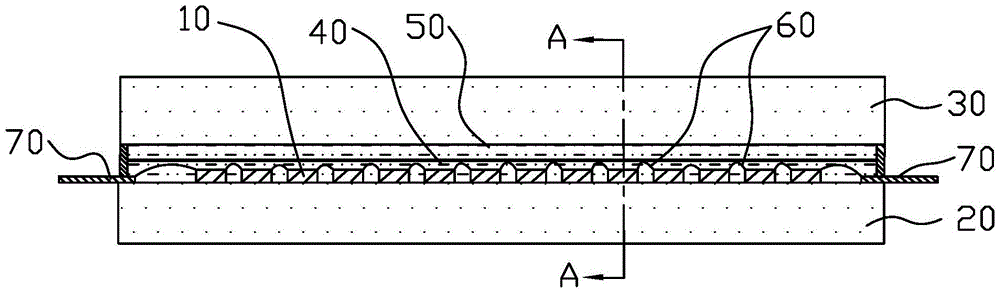

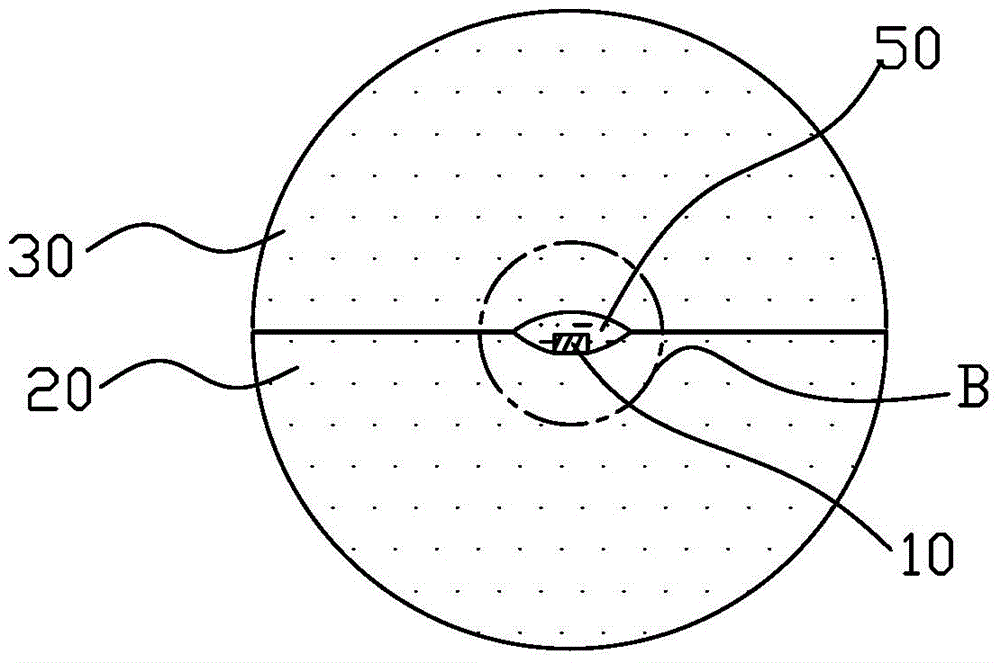

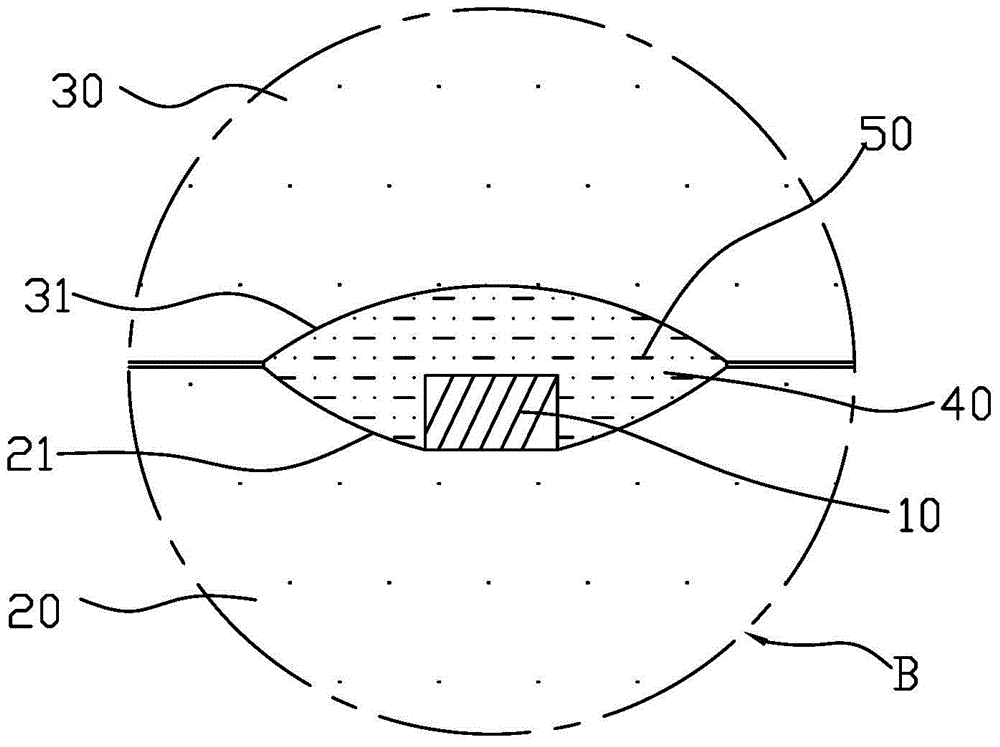

[0014] figure 1 It is a structural schematic diagram of the first embodiment of the packaging structure of the LED light source of the present invention. Please refer to figure 1 The LED light source packaging structure includes LED chips 10 , a base plate 20 and a cover plate 30 , these LED chips 10 are fixed on the base plate 20 , and these LED chips 10 are thermally connected to the base plate 20 .

[0015] Please refer to Figure 1 to Figure 3 The base plate 20 is integrally made of a transparent or translucent heat-conducting material mixed with phosphor powder. Preferably, the base plate 20 is made of phosphor powder and a transparent and highly thermally conductive inorganic material with good chemical compatibility and wettability with the phosphor powder. The bottom plate 20 is provided with a trapezoidal groove 21 (such a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com