Floor drain and water collecting and draining system thereof

A floor drain and funnel technology, applied in waterway systems, drainage structures, water supply devices, etc., can solve the problems of difficult construction, inconvenient repair, maintenance, and difficulty in rework, etc., to improve ground sanitary conditions, improve air environment quality, The effect of reducing the difficulty of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

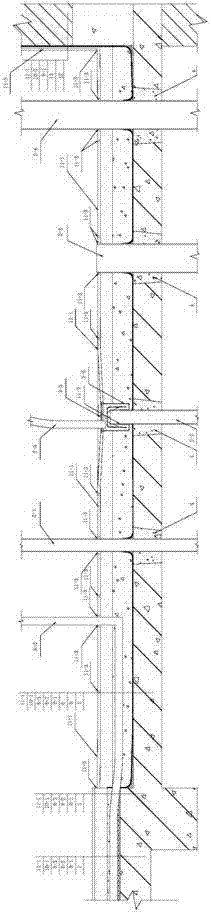

[0063] Embodiment 1. A floor drain, including an anti-odor funnel (3-1), an anti-odor cover (3-2), a water inlet guard (3-3), a large-mouth movable cover grate for pure water filtration (3-4), and its characteristics The reason is: the water inlet of the funnel (3-1) is equipped with a special-shaped non-coil material waterproof joint eaves on the outer ring, the water outlet has a water guide in the pipe and a standard socket outside, and the water-sealed and odor-proof water storage overflow bin is equipped in the funnel. The anti-odor cover (3-2) with water self-cleaning function is snapped into the anti-odor funnel (3-1) and snapped into the overflow nozzle of the water storage overflow bin. The upper part of the funnel has a side water inlet and can The height-adjustable water inlet guard (3-3), the large-mouth movable cover grate for pure water filtration (3-4) or the decorative pure water filter large-mouth movable cover grate (3-5), placed on the water inlet guard (3-4)...

Embodiment 2

[0064] Example 2. A floor drain. On the basis of Example 1, the water-sealed and anti-odor water storage overflow bin and the anti-odor cover in the anti-odor funnel are removed to form a straight-through funnel, and the water inlet guard (3-3) is added. The large-mouth movable cover grate for pure water filtration (3-4) or the large-mouth movable cover grate for pure pure water filtration (3-5) are combined into a low-position direct-buried straight-through floor drain product. (see attached Figure 5 , 6 , 7).

Embodiment 3

[0065] Embodiment 3, a floor drain, on the basis of embodiment 1 or 2, the pure water filter large mouth movable cover grate (3-4) or the pure water filter decorative large mouth movable cover grate (3-5), but they are all Independent monolithic components. (see accompanying drawings 13 and 14).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com