A kind of preparation method of superhydrophobic aluminum and aluminum alloy surface

A kind of aluminum alloy surface and aluminum alloy technology, which is applied to the device for coating liquid on the surface, special surface, plating of superimposed layers, etc., can solve the problems of high price, complicated preparation process, low efficiency, etc., and achieve good surface hydrophobicity Non-toxic, easy to obtain raw materials, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

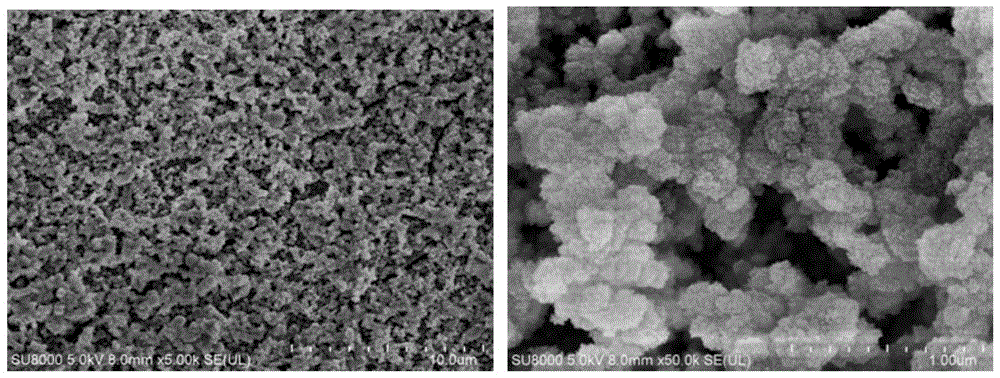

[0033] Wash the aluminum alloy of grade 2024 with water, acetone and ethanol for 5 minutes respectively; For 4h, the concentration of sodium metaaluminate in the mixed solution is 0.15M, and the concentration of urea is 0.6M, obtain as figure 1 The rough surface composed of nanoparticles is shown; then put the aluminum alloy sheet into the reactor, and drop 1-2 drops of 1H,1H,2H,2H-perfluorooctyltriethoxysilane at 110℃ The chemical vapor deposition reaction was carried out under temperature conditions for 2 hours, and the hydrophobic molecules were modified on the surface of the roughened aluminum alloy to obtain a transparent superhydrophobic self-cleaning coating, that is, a superhydrophobic aluminum alloy was obtained.

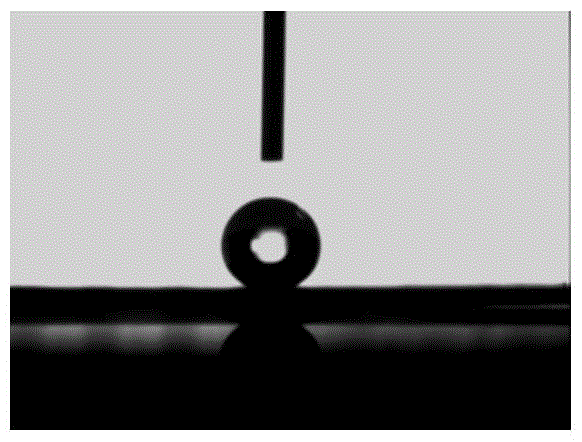

[0034] The distilled water contact angle performance test was carried out on the treated aluminum alloy surface. The test results show that the treated aluminum alloy surface has super-hydrophobic functional properties, and the contact angle of distilled w...

Embodiment 2

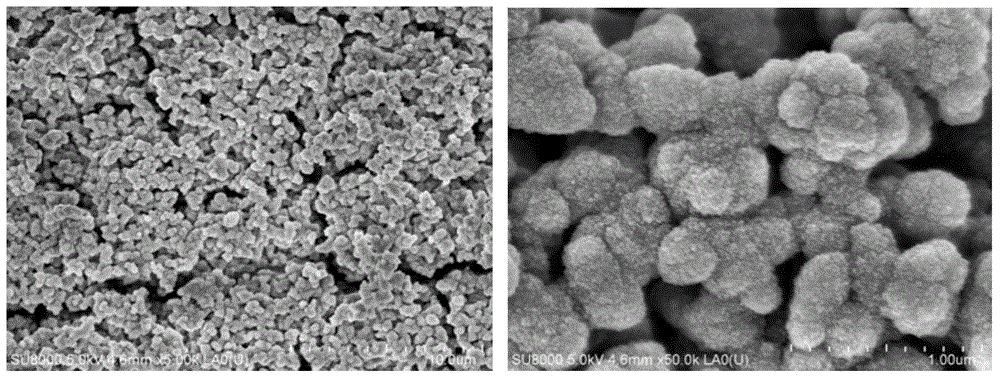

[0036] Wash the aluminum alloy of grade 2024 with water, acetone and ethanol for 5 minutes respectively; For 24h, the concentration of sodium metaaluminate in the mixed solution is 0.15M, and the concentration of urea is 0.6M, obtain as image 3 The rough surface composed of nanoparticles is shown; then the chemical vapor deposition reaction was carried out at 120 ° C for 2 h, and the hydrophobic molecules 1H, 1H, 2H, 2H-perfluorooctyltriethoxysilane were modified on the roughened surface On the surface of the aluminum alloy, a transparent superhydrophobic self-cleaning coating is obtained, that is, a superhydrophobic aluminum alloy is obtained.

[0037] The distilled water contact angle performance test was carried out on the treated aluminum alloy surface. The test results show that the treated aluminum alloy surface has super-hydrophobic functional properties, and the contact angle of distilled water droplets on the aluminum alloy surface reaches 155°±1°, Figure 4Photo o...

Embodiment 3

[0039] Wash the aluminum alloy of grade 2024 with water, acetone and ethanol for 5 minutes respectively; For 2h, the concentration of sodium metaaluminate in the mixed solution is 0.15M, and the concentration of urea is 0.6M; then the aluminum alloy sheet is put into the reactor, and 1-2 drops of 1H, 1H, 2H, 2H-Perfluorooctyltriethoxysilane was subjected to chemical vapor deposition reaction at 120°C for 2 hours, and the hydrophobic molecular alkane was modified on the roughened aluminum alloy surface to obtain a transparent superhydrophobic self-cleaning coating, that is, a superhydrophobic self-cleaning coating. Hydrophobic aluminum alloy.

[0040] The distilled water contact angle performance test was carried out on the treated aluminum alloy surface. The test results show that the treated aluminum alloy surface has super-hydrophobic functional properties, and the contact angle of distilled water droplets on the aluminum alloy surface reaches 150°±1°, Figure 5 Photo of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com