Giant salamander extract and preparation method thereof

A technology of extract and giant salamander, applied in the field of giant salamander extract and its preparation, can solve the problems of high cost, few synthetic methods, large-scale preparation, low content, etc., and achieve the effect of mild conditions, no adverse by-products, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

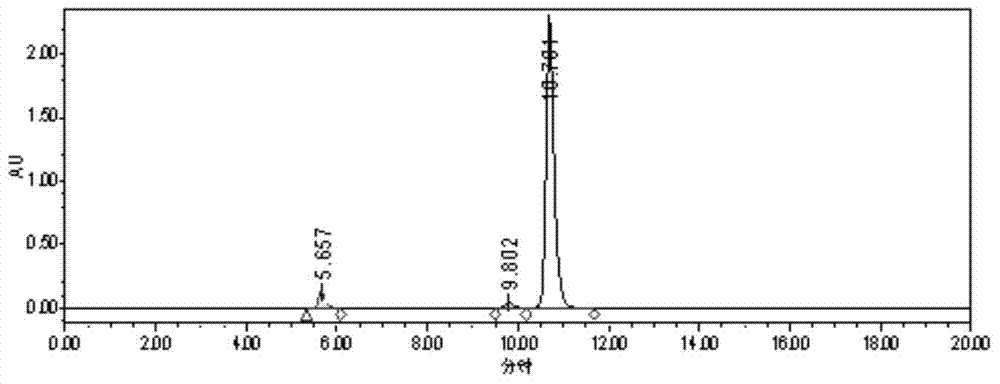

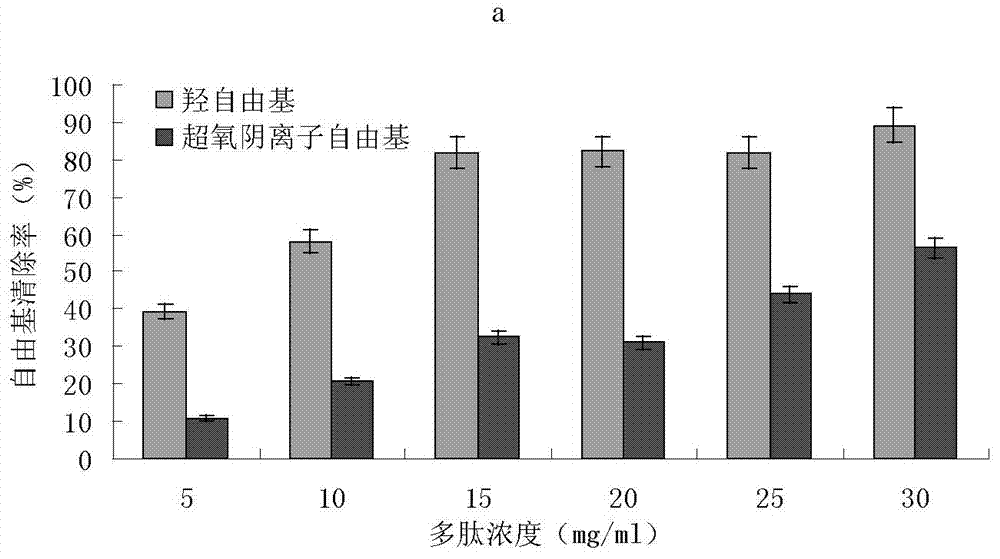

Image

Examples

Embodiment 1

[0045] Make the isolated giant salamander meat tissue into minced meat, add water, the mass ratio of minced meat and water is 1:10, mix well, add enzyme I alkaline protease Alcalase to carry out enzymatic hydrolysis I, the dosage of alkaline protease Alcalase is the total amount of minced meat and water. 0.2% of the mass, the enzymolysis temperature is 45°C, the enzymolysis time is 60min, the enzymolysis pH value is 10, and the stirring speed is 100r / min;

[0046]Add enzyme II flavor protease to the obtained enzymolysis solution I to carry out enzymolysis II, the amount of flavor protease is 0.2% of the mass of enzymolysis solution I, the enzymolysis temperature is 45°C, the enzymolysis time is 30min, and the enzymolysis pH is 7. Take the supernatant by centrifugation (stirring speed 100r / min) to obtain enzymatic hydrolysis solution II, then add activated carbon for decolorization and deodorization, the dosage is 0.3% of the mass of enzymatic hydrolysis solution II, the treatme...

Embodiment 2

[0074] After the isolated giant salamander meat tissue is made into minced meat, add water, the mass ratio of minced meat and water is 1:1, mix well, add enzyme I Alcalase alkaline protease to carry out enzymatic hydrolysis I, the dosage of Alcalase alkaline protease is the total amount of minced meat and water. 0.6% of the mass, the enzymolysis temperature is 55°C, the enzymolysis time is 80min, the enzymolysis pH value is 10, and the stirring speed is 150r / min;

[0075] Add enzyme II flavor protease to the obtained enzymolysis solution I to carry out enzymolysis II, the amount of flavor protease is 0.6% of the mass of enzymolysis solution I, the enzymolysis temperature is 50°C, the enzymolysis time is 30min, and the enzymolysis pH value is 7. Take the supernatant by centrifugation (stirring speed 150r / min) to obtain the enzymatic solution II, then add activated carbon for decolorization and deodorization, the dosage is 0.5% of the mass of the enzymatic solution II, the treatm...

Embodiment 3

[0103] After the isolated giant salamander meat tissue is made into minced meat, add water, the mass ratio of minced meat to water is 1:5, mix well, add enzyme I alkaline protease Alcalase to carry out enzymatic hydrolysis I, the amount of alkaline protease Alcalase is the total amount of minced meat and water. 1.0% of the mass, the enzymolysis temperature is 30°C, the enzymolysis time is 120min, the enzymolysis pH value is 10, and the stirring speed is 250r / min;

[0104] Add enzyme II flavor protease to the obtained enzymolysis solution I to carry out enzymolysis II, the amount of flavor protease is 1.0% of the mass of the enzymolysis solution I, the enzymolysis temperature is 55°C, the enzymolysis time is 30min, and the enzymolysis pH is 9. Centrifuge (stirring speed is 150r / min) to take the supernatant to obtain the enzymatic hydrolysis solution II, then add activated carbon for decolorization and deodorization, the dosage is 0.5% of the mass of the enzymatic hydrolysis solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com