Medium and low temperature coal tar processing method

A technology for low-temperature coal tar and a treatment method, which is applied in the field of coal chemical technology, can solve problems such as heavy component processing, and achieve the effects of stable performance, improved utilization rate, and prolonged catalyst life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

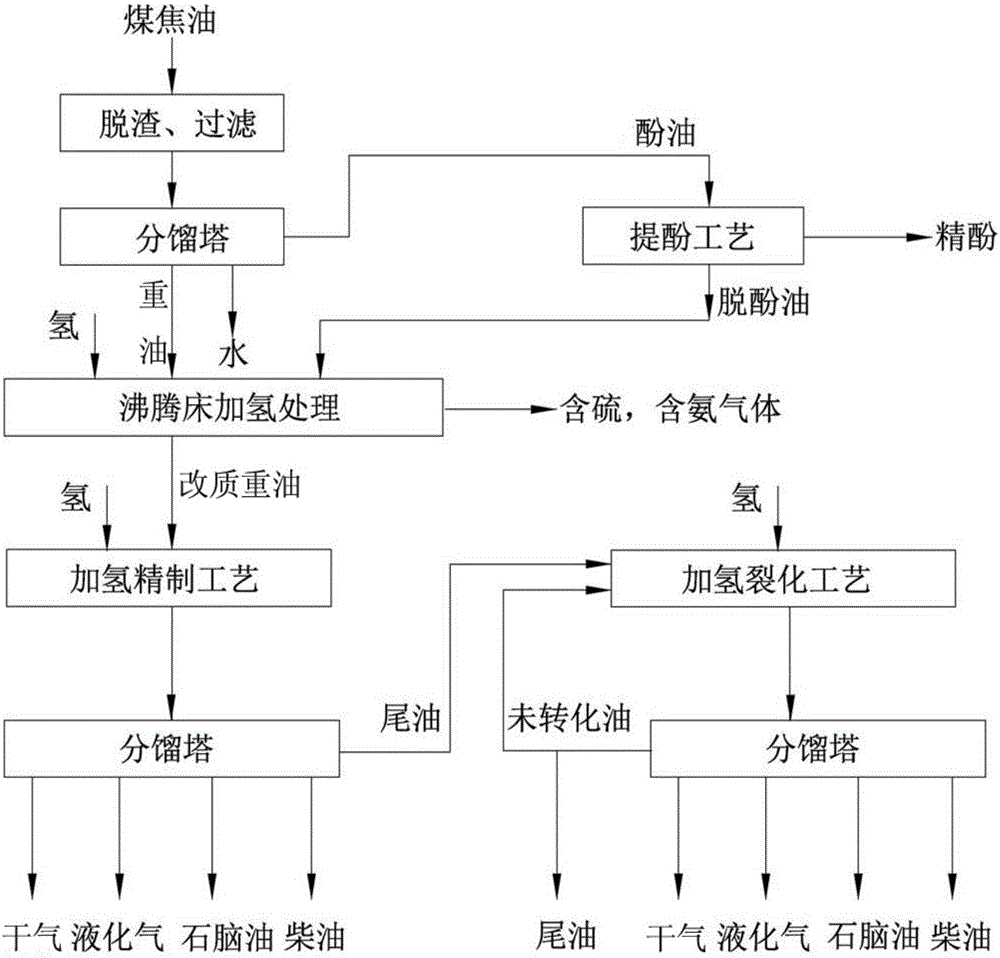

[0041] (1) Low-temperature dry distillation coal tar from lignite in Shenmu County, the properties are shown in Table 1, sent to the pretreatment unit to remove solid impurities, electric desalination and fractional distillation dehydration, and the solids in the coal tar were removed to a diameter of 50um;

[0042] (2) After the treatment in step (1), enter the atmospheric fractionation tower for fractionation, and fractionate water, phenol oil (side stream) and heavy oil;

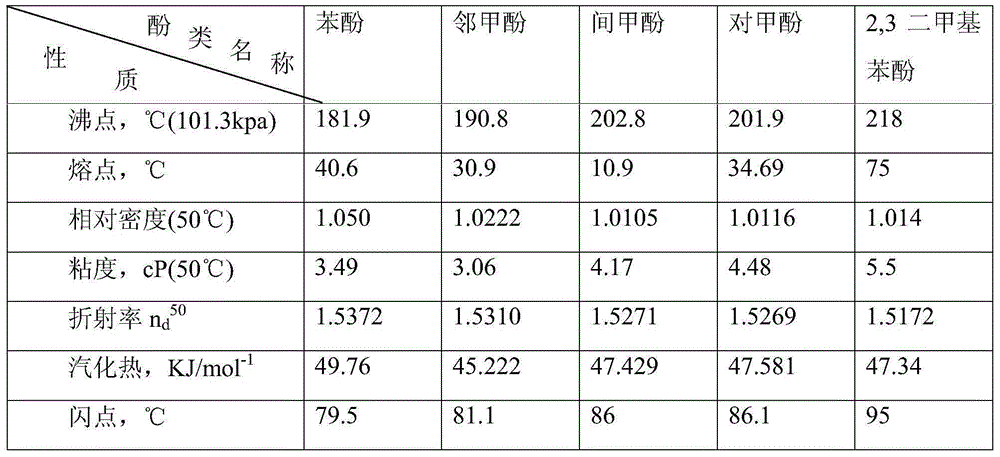

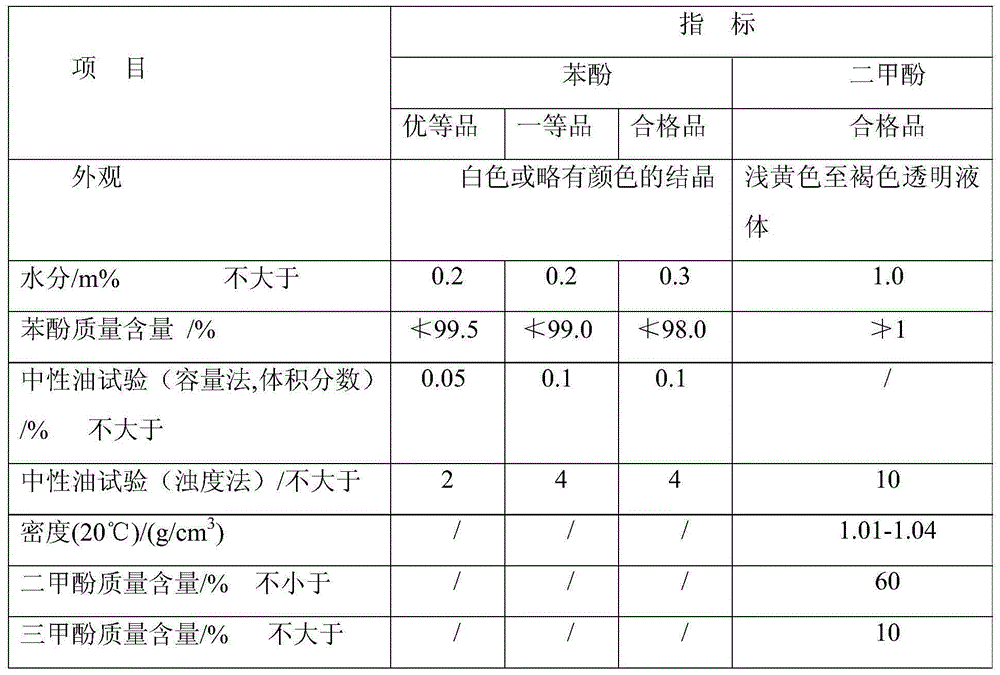

[0043] (3) The phenol oil obtained in step (2) is subjected to phenol extraction treatment, and then enters a phenol oil extraction device to separate refined phenol products and dephenolized oil;

[0044] (4) Mix the heavy oil obtained in step (2) and the dephenolized oil obtained in step (3) into an ebullated bed reactor for hydrogenation reaction to obtain modified heavy oil and sulfur-containing and ammonia-containing gas by-products; the reaction temperature is 360 ℃, reaction pressure 12MPa, hydroge...

Embodiment 2

[0048] (1) Medium and low temperature dry distillation coal tar from lignite in Shenmu County, the properties are shown in Table 2, sent to the pretreatment unit to remove solid impurities, electric desalination and fractional distillation dehydration, and the solids in the coal tar were removed to a diameter of 40um;

[0049] (2) After the treatment in step (1), enter the atmospheric fractionation tower for fractionation, and fractionate water, phenol oil (side stream) and heavy oil;

[0050] (3) The phenol oil obtained in step (2) is subjected to phenol extraction treatment, and then enters a phenol oil extraction device to separate refined phenol products and dephenolized oil;

[0051] (4) Mix the heavy oil obtained in step (2) and the dephenolized oil obtained in step (3) into an ebullated bed reactor for hydrogenation reaction to obtain modified heavy oil and sulfur-containing and ammonia-containing gas by-products; the reaction temperature is 380 ℃, reaction pressure 16M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com