Method for preparing high-adhesive force solid acrylic resin modified by organosilane

A solid acrylic and acrylic resin technology, used in coatings, powder coatings, polyester coatings, etc., can solve the problems of poor adhesion of powder coatings, decreased coating storage, inconvenient operation, etc., to improve adhesion and water resistance. effect of cooking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Add 250g of toluene to a 1000ml four-necked flask equipped with a stirring device, condenser, dropping funnel, thermometer and nitrogen inlet, fill it with nitrogen, heat to reflux, drop the monomer mixture (see Table 1 for the formula), drop Adding time is controlled at 3.5 hours. After the dropwise addition is completed, cool down to 70°C and keep the temperature for 3 hours. Dissolve 3g of 2,2′-azobisisobutyronitrile with 20g of toluene and add it to the reaction system at one time. Insulated and refluxed for 1.5 hours. Use normal pressure distillation to remove most of the solvent. When a small amount of solvent remains, you can use reduced pressure distillation to remove the solvent, discharge while hot, cool, and pulverize. Finally, the product silane-modified acrylic resin 1 was obtained.

Embodiment 2-3

[0020] Example 2-3 The preparation method is the same as that of Example 1. The ratio of the monomer mixture is shown in Table 1. Silane-modified acrylic resins 2 and 3 were prepared respectively. The experimental results are shown in Table 1.

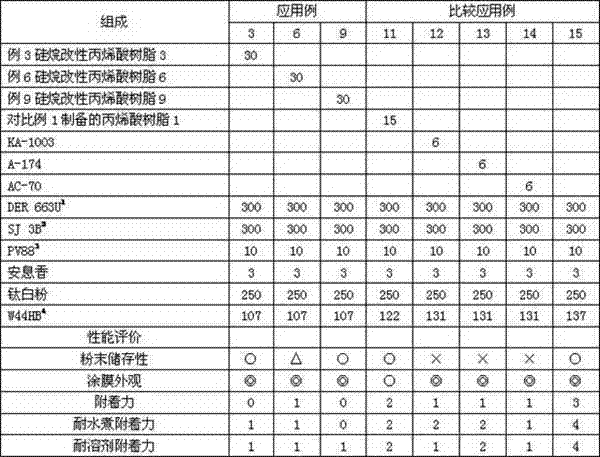

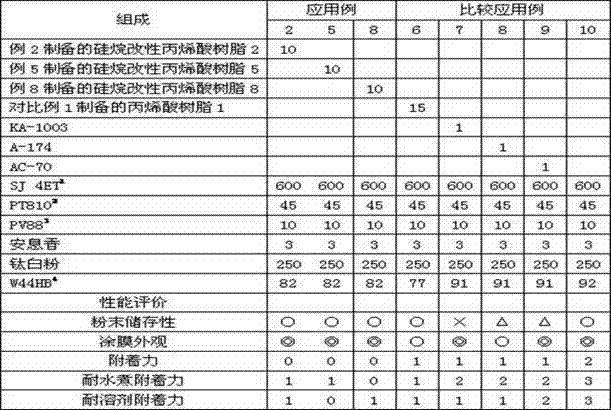

[0021] Table 1

[0022]

[0023] *:Vinyltrichlorosilane

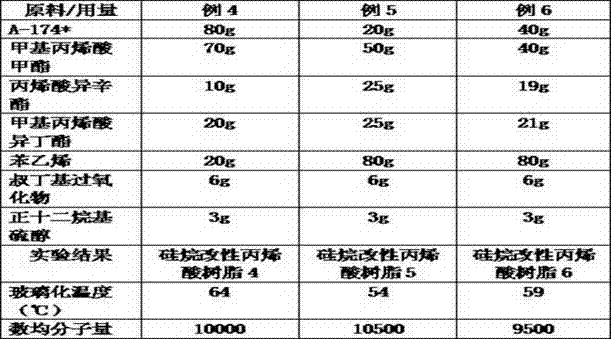

Embodiment 4

[0025] Add 250g of toluene to a 1000ml four-necked flask equipped with a stirring device, condenser, dropping funnel, thermometer and nitrogen inlet, fill it with nitrogen, heat to reflux, drop the monomer mixture (see Table 2 for the formula), drop Adding time is controlled at 3.5 hours. After the dropwise addition is completed, cool down to 90°C and keep the reaction at this temperature for 3 hours. Dissolve 2g of tert-butyl peroxide in 20g of toluene and add it to the reaction system at one time, then keep warm and reflux for 1 hour. Use normal pressure distillation to remove most of the solvent. When a small amount of solvent remains, you can use reduced pressure distillation to remove the solvent, discharge while hot, cool, and pulverize. Finally, a silane-modified acrylic resin 4 was obtained. The experimental results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com