Dolomite-periclase-calcium zirconate composite fireproof material and preparation method thereof

A refractory material, calcium zirconate technology, applied in the field of smelting refractory materials, can solve the problems of poor thermal shock stability, poor hydration resistance, no corrosion resistance, etc., to improve performance, reduce sintering temperature, and increase service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

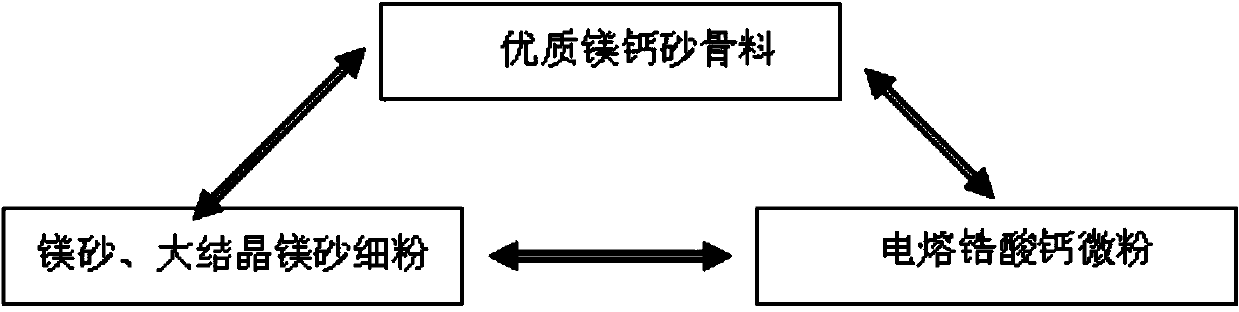

Method used

Image

Examples

Embodiment Construction

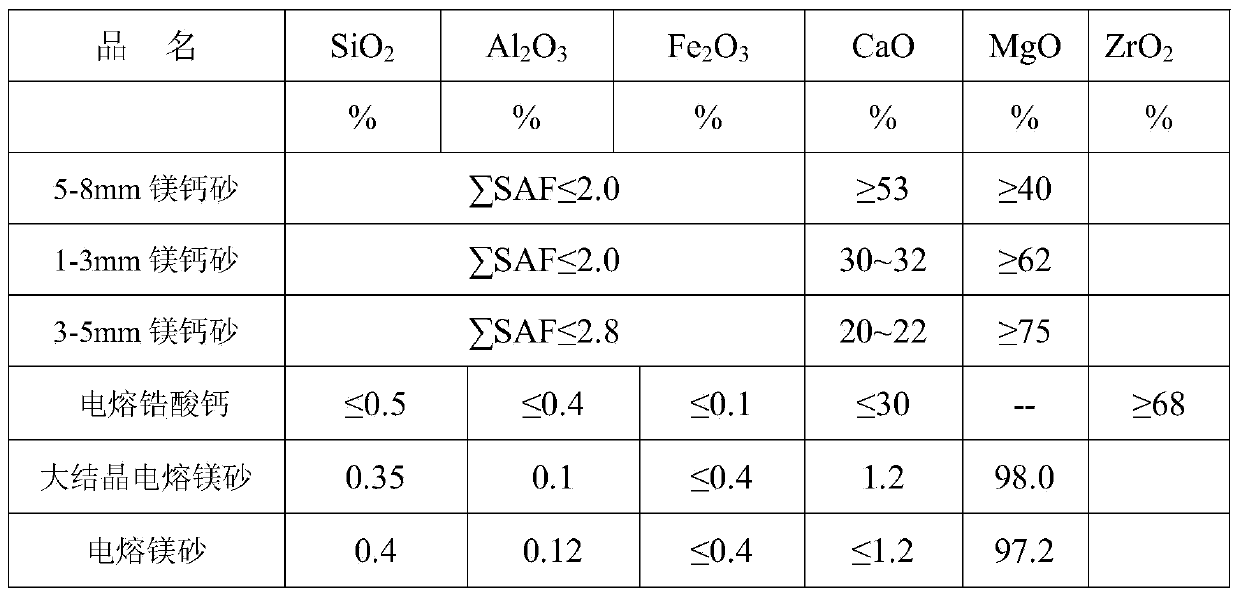

[0029] High-quality dolomite-periclase-calcium zirconate composite refractory material is prepared from the following raw materials by weight percentage: 5-8mm magnesia-calcium sand 8-10%; 3-5mm magnesia-calcium sand 9-18%; 1 -3mm magnesia calcium sand 10-22%; 0.5-1mm fused calcium zirconate 5-10%; 0.5-1mm magnesia 5-10%; 600 mesh fused calcium zirconate 3-10%; ≤0.5 mm magnesia 15-24%; large crystal magnesia 3-10%; binder 1-3%; sintering agent 1-2%.

[0030] The binding agent is made by dehydrating paraffin wax.

[0031] The sintering agent can be selected from any of the following materials: aluminum oxide, titanium oxide, boron oxide, and cerium oxide.

[0032] Prepare this high-quality dolomite-periclase-calcium zirconate composite refractory material based on 1000 kg of refractory material, the steps are as follows:

[0033] 1) Material preparation: The magnesia-calcium sand is mechanically crushed through the jaw crusher, the roller crusher, and the cone crusher in sequ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com